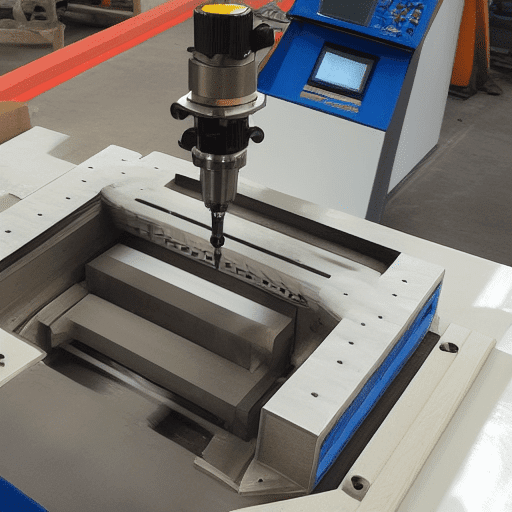

A CNC router is a computer-controlled cutting machine used to cut a variety of materials, such as wood, plastic, and metal. While CNC routers offer a number of advantages, such as increased accuracy and repeatability, they also have some disadvantages.

One of the main disadvantages of using a CNC router is the cost. CNC routers are expensive, and the cost of the machine itself is only the beginning. In addition to the cost of the machine, you will also need to purchase software, tools, and materials. This can add up quickly, making CNC routers cost-prohibitive for some people.

Another disadvantage of CNC routers is the complexity of the machines. CNC routers are highly complex machines, and require a certain level of technical knowledge to operate. This means that it can take a significant amount of time to learn how to use a CNC router, and even more time to become proficient.

Finally, CNC routers require a significant amount of maintenance. The machines need to be regularly cleaned and lubricated, and the tools need to be sharpened or replaced. This can be time-consuming and costly, and can add to the overall cost of using a CNC router.

Overall, while CNC routers offer a number of advantages, they also have some significant disadvantages. The cost of the machine, the complexity of the machine, and the amount of maintenance required can all add up, making CNC routers cost-prohibitive for some people.

What are some disadvantages of using CNC?

CNC (Computer Numerical Control) is a type of automation technology used in manufacturing processes that involves the use of computers to control machine tools. CNC machines are used to produce parts with high precision and accuracy, and can be used to produce parts in large quantities. While CNC machines offer many advantages, there are also some disadvantages associated with their use.

One of the main disadvantages of CNC machines is their high cost. CNC machines are more expensive than traditional machine tools, and require a significant investment in both the machine and the software used to control it. Additionally, CNC machines require specialized training and expertise to operate, which can add to the cost of using them.

Another disadvantage of CNC machines is that they are not as flexible as traditional machine tools. CNC machines are programmed to perform specific tasks, and cannot be easily adapted to perform different tasks. This means that if a part needs to be changed or modified, the CNC machine must be reprogrammed, which can be time consuming and costly.

What are the disadvantages of milling machine?

Milling machines can be very expensive, especially when compared to other types of machining tools. They also require a large amount of space in a workshop, as they are typically much larger than other types of machining tools. Additionally, milling machines require a significant amount of setup time before they can be used, which can be costly in terms of both time and money. Furthermore, milling machines are not as precise as other types of machining tools, and they can be difficult to use for certain types of materials. Finally, milling machines can be quite loud, which can be a nuisance in a workshop environment.

What are the advantages and disadvantages of a CNC router?

Advantages of a CNC Router:

1. Increased Accuracy: CNC routers are capable of producing parts with a high degree of accuracy and repeatability. This is due to the fact that the machine is programmed to follow a specific set of instructions, which eliminates the possibility of human error.

2. Increased Speed: CNC routers are capable of producing parts at a much faster rate than manual machines. This is due to the fact that the machine is programmed to follow a specific set of instructions, which eliminates the need for manual labor.

3. Increased Versatility: CNC routers are capable of producing parts in a variety of materials, including wood, plastic, metal, and composites. This is due to the fact that the machine is programmed to follow a specific set of instructions, which eliminates the need for manual labor.

4. Reduced Labor Costs: CNC routers are capable of producing parts with minimal labor costs. This is due to the fact that the machine is programmed to follow a specific set of instructions, which eliminates the need for manual labor.

What are the advantages of CNC?

CNC (Computer Numerical Control) is a type of automation technology that uses computer-controlled machines to perform a variety of tasks. CNC machines are used in a wide range of industries, from aerospace to automotive, and offer a number of advantages over traditional manual machining.

One of the primary advantages of CNC machines is their accuracy and repeatability. CNC machines are programmed with precise instructions, and can be used to produce parts with extremely tight tolerances. This makes them ideal for producing parts with complex shapes and intricate details. CNC machines are also able to produce parts with a high degree of consistency, which is important for mass production.

Another advantage of CNC machines is their speed. CNC machines are able to produce parts much faster than manual machines, which can significantly reduce production time and costs. CNC machines are also able to produce parts with a high degree of complexity, which can be difficult or impossible to achieve with manual machines.

What are the advantages and disadvantages of CNC machines over conventional machines?

The advantages of CNC machines over conventional machines are numerous. CNC machines are more precise and accurate than conventional machines, allowing for greater accuracy and repeatability in the production of parts. CNC machines are also faster than conventional machines, allowing for faster production times and higher output. CNC machines are also more versatile than conventional machines, allowing for the production of a wider variety of parts. Additionally, CNC machines are easier to program and operate than conventional machines, allowing for greater flexibility in the production process.

The disadvantages of CNC machines over conventional machines are also numerous. CNC machines are more expensive than conventional machines, making them cost prohibitive for some applications. Additionally, CNC machines require more maintenance than conventional machines, as they are more complex and require more frequent calibration and maintenance. CNC machines also require more skilled operators than conventional machines, as they require a greater understanding of the programming and operation of the machine. Finally, CNC machines are more difficult to repair than conventional machines, as they require specialized tools and knowledge to repair.

Is CNC machine noisy?

CNC machines can be noisy depending on the type of machine and the type of work being done. Generally, CNC machines are louder than manual machines because they use high-speed spindles and cutting tools. The noise level of a CNC machine can range from a low hum to a loud roar, depending on the type of machine and the type of work being done. For example, a CNC milling machine will be louder than a CNC lathe because the milling machine is cutting metal at a much higher speed. Additionally, the type of cutting tool being used can also affect the noise level. For example, a high-speed steel cutting tool will be louder than a carbide cutting tool.

In addition to the noise generated by the machine itself, the environment in which the machine is operating can also affect the noise level. For example, if the machine is in a room with poor acoustics, the noise level will be higher than if the machine is in a room with good acoustics. Additionally, the type of material being cut can also affect the noise level.

What is the biggest disadvantage of using CNC?

The biggest disadvantage of using CNC (Computer Numerical Control) is the cost. CNC machines are expensive to purchase and maintain, and require a significant amount of training to operate. Additionally, CNC machines require a large amount of energy to run, which can be costly. Furthermore, CNC machines are not as flexible as manual machines, as they are limited to the specific programming that is used to control them. This means that if a part needs to be changed or modified, the entire program must be re-written, which can be time consuming and costly. Finally, CNC machines are not as accurate as manual machines, as they are limited by the precision of the programming. This can lead to errors in the finished product, which can be costly to fix.

What is not the advantage of CNC machine?

One of the main advantages of CNC machines is their ability to produce parts with high accuracy and repeatability. However, this is not the only advantage of CNC machines. Other advantages include their ability to produce complex shapes, their ability to produce parts quickly, their ability to produce parts with a high degree of consistency, and their ability to produce parts with a high degree of precision.

However, one of the disadvantages of CNC machines is their high cost. CNC machines are typically more expensive than traditional machining methods, such as manual machining. Additionally, CNC machines require a high level of skill and knowledge to operate, and they require a significant amount of maintenance and upkeep. Furthermore, CNC machines are not suitable for all types of machining, as they are limited in the types of materials they can work with.

What are the advantages of using CNC machines?

The use of CNC machines offers a number of advantages over traditional manual machining. CNC machines are able to produce parts with greater accuracy and repeatability than manual machining, as they are programmed to follow a specific set of instructions. This means that the same part can be produced multiple times with the same exact specifications. CNC machines also offer greater speed and efficiency than manual machining, as they are able to complete complex tasks in a fraction of the time it would take a human operator. Additionally, CNC machines are able to produce parts with greater precision and detail than manual machining, as they are able to cut and shape materials with greater accuracy and consistency. CNC machines also require less manual labor, as they are able to operate autonomously, meaning that fewer workers are needed to operate them. Finally, CNC machines are able to produce parts with greater complexity than manual machining, as they are able to produce parts with intricate shapes and designs that would be difficult or impossible to produce with manual machining.

Is CNC machine noisy?

CNC machines can be noisy depending on the type of machine and the type of work it is doing. Generally, CNC machines are louder than manual machines because they use high-speed spindles and cutting tools. The noise level of a CNC machine can range from a low hum to a loud roar, depending on the type of machine and the type of work it is doing. For example, a CNC milling machine will be much louder than a CNC lathe because the milling machine is cutting metal at a much higher speed. Additionally, the type of cutting tool being used can also affect the noise level. For example, a high-speed steel cutting tool will be much louder than a carbide cutting tool. In addition to the noise from the machine itself, the environment in which the machine is operating can also affect the noise level. If the machine is in a room with poor acoustics, the noise level can be amplified.

What are the disadvantages of machining?

Machining is a process that involves cutting and shaping materials to create a desired product. While it is a highly efficient and precise method of manufacturing, there are some disadvantages associated with it.

One of the main disadvantages of machining is the cost. Machining is a labor-intensive process that requires specialized equipment and highly trained personnel. This can make it expensive to set up and maintain a machining operation. Additionally, the cost of the materials used in machining can be high, as they must be of a certain quality and grade to ensure the accuracy and precision of the finished product.

Another disadvantage of machining is the time it takes to complete a job. Machining is a slow process, as each step must be completed with precision and accuracy. This can lead to long lead times for projects, which can be a problem for businesses that need to meet tight deadlines.

The accuracy of machining is also a disadvantage. While machining is a highly precise process, it is not perfect.

What is the difference between conventional and CNC machines?

The primary difference between conventional and CNC (Computer Numerical Control) machines is the means by which the machine is controlled. Conventional machines are manually operated, meaning that the operator must manually control the machine’s movements and functions. CNC machines, on the other hand, are computer-controlled, meaning that the machine is programmed to perform specific tasks and functions.

Conventional machines are typically used for simpler tasks, such as drilling, milling, and turning. These machines are relatively inexpensive and require minimal training to operate. CNC machines, however, are more complex and are used for more intricate tasks, such as engraving, cutting, and shaping. CNC machines are more expensive and require more training to operate.

Another difference between conventional and CNC machines is the level of precision they can achieve. Conventional machines are limited in their precision, as they are manually operated and can only achieve a certain level of accuracy.

Are CNC routers worth it?

CNC routers can be a great investment for businesses that need to produce a large number of parts quickly and accurately. CNC routers are computer-controlled machines that use a cutting tool to cut out parts from a variety of materials, such as wood, plastic, and metal. They are capable of producing parts with a high degree of accuracy and repeatability, and can be programmed to produce parts with complex shapes and intricate details. CNC routers are also relatively easy to use, and can be operated by a single person with minimal training.

The cost of a CNC router can vary greatly depending on the size and capabilities of the machine, but they are generally more expensive than manual routers. However, the cost of a CNC router can be offset by the increased efficiency and accuracy that it provides. CNC routers can also be used to produce parts in large quantities, which can help to reduce the cost of production.

Overall, CNC routers can be a great investment for businesses that need to produce a large number of parts quickly and accurately.