CNC programming has become an increasingly popular career choice in recent years due to its potential for job security and high earning potential. It is a technical field that requires a strong understanding of computer-aided design (CAD) and computer-aided manufacturing (CAM) software, as well as a basic knowledge of mathematics, physics, and engineering principles. With the right training and experience, CNC programmers can become highly sought after professionals in a wide variety of industries. As the demand for skilled CNC programmers increases, the job outlook for this profession looks positive.

The Benefits of CNC Programming as a Career Choice

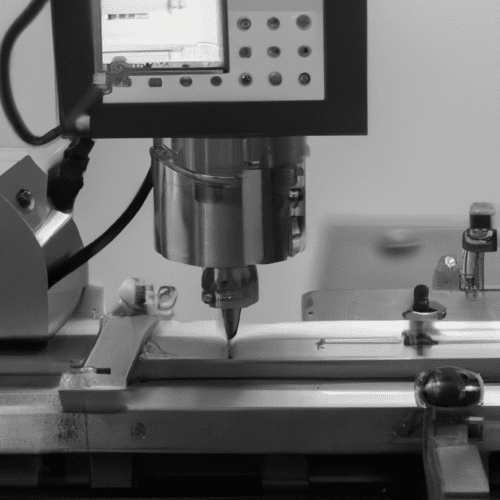

CNC programming is a highly sought-after career choice in the manufacturing industry. It provides a stable career path with competitive salaries and a wide range of job opportunities. CNC programming is a technical field that combines engineering knowledge with computer programming skills. It requires a comprehensive understanding of CAD/CAM software, G-code programming, machining processes, and geometry. CNC programming is an attractive career choice due to its stability. CNC programmers are in demand across many industries, and the job outlook for the future is positive. This demand is driven by the rise in computer-aided manufacturing (CAM) technology, which is used to create complex and accurate parts. The precision and repeatability of CNC machines are what make them so desirable in the manufacturing industry. In addition to job stability, CNC programming is a lucrative career choice. CNC programmers typically earn salaries that are above the national average.

The salary range varies depending on experience level, but experienced CNC programmers can earn salaries in the six-figure range. CNC programming is also a versatile career choice. CNC programmers can specialize in a wide range of areas, from aerospace to medical device manufacturing. This allows CNC programmers to gain experience and knowledge in different industries, as well as expand their skill set. Overall, CNC programming is a great career choice. It offers job stability, a competitive salary, and the potential to specialize in different areas. Those interested in CNC programming should pursue a degree in engineering or computer science, as well as gain experience with CAD/CAM software and machining processes. With the right qualifications and experience, CNC programming can lead to a long and rewarding career.

What Education and Training is Needed to Become a CNC Programmer?

Becoming a CNC (Computer Numerical Control) Programmer requires specialized education and training. A high school diploma or GED is a prerequisite, and post-secondary education is highly recommended. An Associate’s degree in Computer Numerical Control (CNC) Programming or a related field is often preferred. Additionally, certification in CNC programming is available and can be beneficial for career advancement. CNC Programmers must have a strong understanding of the principles of industrial technology, mathematics, and engineering. They must be able to read and interpret blueprints and CAD (Computer Aided Design) drawings, and be proficient in the use of computers and CNC machinery.

Familiarity with G-code programming language is also essential. Employers may provide additional on-the-job training for CNC Programmers to teach them how to operate and program their equipment. This type of training can range from a few days to several weeks, depending on the complexity of the machinery and the capabilities of the programmer. In addition to formal education and training, CNC Programmers must also possess certain personal qualities, such as strong problem-solving skills, attention to detail, and the ability to work in a fast-paced environment.

How the CNC Programming Industry is Evolving

The CNC programming industry is continuing to evolve in order to keep up with the rapid advancements in technology. As technology continues to improve, CNC programming is becoming more sophisticated and precise in its capabilities. One of the most notable advancements in CNC programming is the implementation of 3D printing and machining technology. This has allowed CNC programmers to create more complex and intricate parts with greater precision than ever before. This technology has also enabled CNC programmers to work with a wider range of materials, including metals, plastics and composites. Another major advancement in the industry is the use of simulation software and virtual prototyping. This technology allows CNC programmers to test and refine their programs in a virtual environment before they are implemented on the actual machine. This allows for more efficient and accurate programming, as well as reducing the cost of production.

The use of advanced robotics and automation is also becoming more prevalent in the CNC programming industry. Robotics and automated systems are being used to increase productivity and reduce labor costs. This technology is also allowing CNC programmers to focus on more complex tasks, such as designing and programming robots to perform complicated tasks. Finally, CNC programming is becoming more accessible and user-friendly thanks to the advent of cloud computing and mobile applications. These tools allow CNC programmers to work remotely and collaborate with teams from around the world. This has opened up the CNC programming industry to a larger pool of talent, as well as allowing for more efficient and cost-effective programming. All in all, the CNC programming industry is continuing to evolve and improve in order to keep up with the demands of modern technology. As these advancements continue to be implemented, CNC programming will become more efficient, precise and cost-effective for businesses and consumers alike.

Exploring the Different Types of CNC Programmers

CNC (Computer Numerical Control) programming is a specialized field of engineering that requires knowledge of a variety of disciplines, including mathematics, computer science, and engineering. As such, there are several different types of CNC programmers, each with their own strengths and weaknesses. The most common type of CNC programmer is the manual programmer. These programmers use traditional, manual programming techniques to create programs for CNC machines. Manual programming requires a great deal of skill and experience, and can be time consuming. Another type of CNC programmer is the conversational programmer. This type of programmer writes programs in a conversational language, allowing them to quickly create programs for CNC machines without the need for complex mathematical equations. Conversational programming is often used for simple, repetitive tasks. A third type of CNC programmer is the CAD/CAM programmer.

This type of programmer uses computer-aided design and manufacturing software to create complex, three-dimensional designs that are then converted into programs for CNC machines. CAD/CAM programming is well-suited for complex projects that require detailed designs. Finally, a fourth type of CNC programmer is the parametric programmer. This type of programmer creates programs by entering parameters that define the shape, size, and other characteristics of the part being manufactured. Parametric programming is often used for projects that require highly precise parts with exact specifications. Each of these CNC programming types has its own strengths and weaknesses. It is important to understand the differences between them in order to choose the best type of programmer for a particular project.

Skilled CNC Programmers: What Makes Them Special?

Skilled CNC programmers are highly sought after in the machining industry due to their specialized knowledge and expertise. They are responsible for creating CNC programs for automated machines, which are used in a variety of industries such as automotive, aerospace, and medical. CNC programmers must have a thorough understanding of the various control systems, cutting tools, and materials used in the machining process. They must also be knowledgeable about the various programming languages used to create CNC programs. Additionally, they must have a keen eye for detail and be able to troubleshoot any issues that may arise with the program or machine. Skilled CNC programmers are also highly organized and meticulous. They must be able to work with precision and accuracy to ensure that the CNC program will run as expected. They must also be able to work quickly and efficiently to meet tight deadlines. Overall, skilled CNC programmers are highly sought after due to their specialized knowledge, expertise, and attention to detail. They are a valuable asset to any machining company, as they are the ones responsible for creating the CNC programs that make the work of the machinists easier.