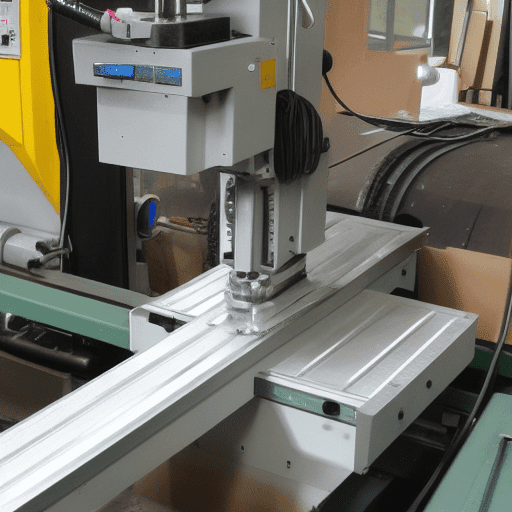

CNC milling machines are automated milling machines used to produce high precision parts with tight tolerances. They are controlled by a computer program that directs the movements of the cutting tool and the workpiece. A CNC milling machine offers various operations to be carried out, including drilling, boring, reaming, tapping, counterboring, countersinking, and milling.

Drilling involves creating cylindrical holes in the workpiece by rotating a drill bit at high speed and feeding it into the material. As the cutting edges of the drill bit remove material, the hole is formed in the workpiece.

Boring is the process of enlarging an existing hole. The boring tool is held in a spindle and is rotated at high speed while being fed into the workpiece. The cutting edges of the boring tool remove material from the workpiece to enlarge the hole.

Reaming is the process of creating a smooth, accurate hole in a workpiece. The reamer is held in a spindle and is rotated at high speed while being fed into the workpiece. The cutting edges of the reamer remove material from the workpiece to create the hole.

Tapping is the process of creating a threaded hole in a workpiece. The tap is held in a spindle and is rotated at high speed while being fed into the workpiece. The cutting edges of the tap remove material from the workpiece to create the threaded hole.

Counterboring is the process of enlarging the top of a hole to a larger diameter. The counterbore is held in a spindle and is rotated at high speed while being fed into the workpiece. The cutting edges of the counterbore remove material from the workpiece to enlarge the hole.

Countersinking is the process of creating a conical hole in a workpiece. The countersink is held in a spindle and is rotated at high speed while being fed into the workpiece. The cutting edges of the countersink remove material from the workpiece to create the conical hole.

What are different types of milling operations?

There are several different types of milling operations, each tailored to specific machining requirements and producing various shapes and features. Some common types of milling operations include:

- Face Milling: In face milling, the cutting tool’s axis is perpendicular to the workpiece surface. It is used to create flat surfaces and is often employed for roughing large areas.

- Peripheral Milling (or Slab Milling): In peripheral milling, the cutting tool’s axis is parallel to the surface being machined. It is commonly used to create flat surfaces, slots, and pockets.

- End Milling: End milling involves milling with the cutting tool’s end face, making it suitable for creating slots, pockets, and complex contours.

- Profile Milling: Profile milling is used to produce complex shapes or contours on the workpiece surface, where the cutting tool’s path follows the outline of the desired shape.

- Plunge Milling: Plunge milling is a type of end milling where the cutting tool is plunged into the workpiece to create holes or cavities.

- Ramp Milling: In ramp milling, the cutting tool is gradually ramped into the workpiece, allowing for smoother entry and exit of the tool, reducing tool wear and providing better surface finish.

- Pocket Milling: Pocket milling involves milling out material from a pocket or cavity in the workpiece, leaving a flat bottom surface.

- Drilling: Although drilling is a separate operation, it can be performed using a milling machine. It involves creating cylindrical holes in the workpiece using a rotating drill bit.

- Thread Milling: Thread milling is used to create threads on the workpiece by moving the cutting tool along a helical path.

- Gear Milling: Gear milling is employed to cut gears on the workpiece, either using specialized gear milling cutters or with the assistance of indexing.

- 3D Contouring: 3D contouring is used to produce intricate three-dimensional shapes and surfaces, often found in sculptural or artistic applications.

What is a 5 axis CNC machine?

A 5 axis CNC machine is a computer numerically controlled (CNC) machine that is capable of moving a tool or cutting head along five different axes simultaneously. This type of machine is used in a variety of industries, including aerospace, automotive, and medical device manufacturing. The five axes of motion are typically labeled X, Y, Z, A, and B. The X and Y axes are typically used for linear motion, while the Z axis is used for vertical motion. The A and B axes are used for rotational motion, allowing the tool or cutting head to move in a circular motion.

The 5 axis CNC machine is capable of producing complex parts with intricate shapes and details that would be difficult or impossible to produce with traditional machining methods. This type of machine is also capable of producing parts with a high degree of accuracy and repeatability. The 5 axis CNC machine is typically used for milling, drilling, and cutting operations, and can be used to produce parts from a variety of materials, including metals, plastics, and composites.

What are the five steps in the milling process?

T milling machine being used.

2. Setting the Workpiece: The next step is to set the workpiece in the milling machine. This involves positioning the workpiece in the correct orientation and securing it in place.

3. Setting the Cutting Parameters: The cutting parameters must be set before the milling process can begin. This includes the speed of the cutting tool, the feed rate, and the depth of cut.

4. Machining the Workpiece: Once the cutting parameters have been set, the milling machine can begin machining the workpiece

How many types of milling process are there?

The milling process involves the removal of material from a workpiece using a rotating cutting tool. There are typically five essential steps in the milling process:

- Face Milling: The first step involves securing the workpiece on the milling machine’s worktable. Face milling is used to create a flat surface on the top face of the workpiece. A face milling cutter with multiple cutting edges rotates and moves across the workpiece, shaving off material to achieve a smooth and even surface.

- Peripheral Milling: In this step, the milling cutter moves along the periphery or outer edges of the workpiece. This operation is commonly used to create straight edges, contours, or slots. Depending on the desired outcome, the cutter may move along the workpiece’s outer profile horizontally (along the X-axis) or vertically (along the Y-axis).

- End Milling: End milling involves cutting on the side of the workpiece using an end mill, which has cutting edges on the bottom and side of the tool. This process is used to create slots, pockets, and other features on the workpiece’s side. The end mill moves horizontally along the X-axis and may also move vertically along the Z-axis to achieve the desired depth of cut.

- Drilling: Drilling is a crucial step that involves creating cylindrical holes in the workpiece. A drill bit is used, and the rotating motion of the bit, along with a downward force, creates the hole. The drilling operation can be performed with the workpiece stationary or while moving the drill vertically (Z-axis) into the workpiece.

- Reaming: After drilling, the holes may have rough edges and inaccuracies. Reaming is the process of using a reamer tool to refine and improve the accuracy and surface finish of the drilled holes. The reamer is rotated and fed into the existing hole, removing a small amount of material to create a smoother, more precise hole.

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. There are several different types of milling processes, each of which has its own advantages and disadvantages. The most common types of milling processes are peripheral milling, face milling, end milling, and contour milling.

Peripheral milling is a process in which the cutting tool moves along the circumference of the workpiece. This type of milling is used to create slots, grooves, and other features on the outer surface of the workpiece. It is also used to create flat surfaces on the workpiece.

Face milling is a process in which the cutting tool moves perpendicular to the surface of the workpiece. This type of milling is used to create flat surfaces on the workpiece. It is also used to create slots, grooves, and other features on the surface of the workpiece.

Which of the following operation can be performed with milling cutter?

Milling cutters are a type of cutting tool used in milling machines or machining centers to perform milling operations (and occasionally in other machine tools). They remove material by their movement within the machine (e.g., a ball nose mill) or directly from the cutter’s shape (e.g., a form tool such as a hobbing cutter).

Milling cutters can be used to perform a variety of operations, including facing, slotting, pocketing, drilling, reaming, and tapping. Facing is the process of removing material from the end of a workpiece to produce a flat surface. Slotting is the process of cutting slots or grooves into a workpiece. Pocketing is the process of cutting out a pocket or recess in a workpiece. Drilling is the process of creating a hole in a workpiece. Reaming is the process of enlarging a hole that has already been drilled. Tapping is the process of cutting threads into a hole to create a threaded hole.

What is the function of a milling machine?

A milling machine is a machine tool used for the shaping of metal and other solid materials. Its basic form is that of a rotating cutter or endmill which rotates about the spindle axis (similar to a drill), and a movable table to which the workpiece is affixed. Milling machines are used to shape flat and irregular surfaces, cut grooves, slots, and gear teeth, and to drill, bore, and ream holes. They are also used to produce a variety of other shapes and contours.

Milling machines are typically classified according to the number of axes on which they can operate. The most common types are the vertical milling machine and the horizontal milling machine. The vertical milling machine has a spindle axis that is vertical and the table moves perpendicular to the spindle axis. The horizontal milling machine has a spindle axis that is horizontal and the table moves parallel to the spindle axis.