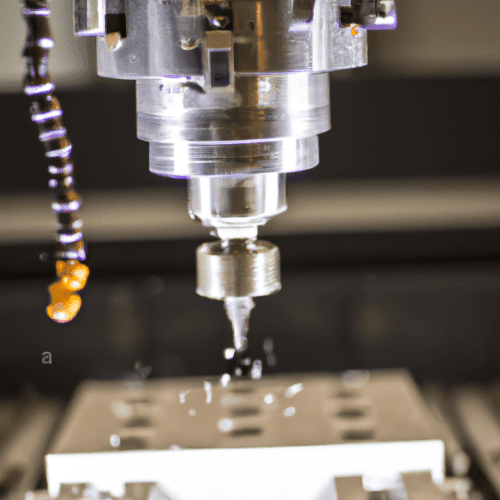

Milling is a machining process that involves the use of a rotating cutting tool to remove material from a workpiece. It is commonly used in the manufacturing industry to create parts with precise dimensions and shapes. Milling can be used to create a variety of shapes and features on a workpiece, including flat surfaces, curved surfaces, slots, grooves, and other complex shapes. It can also be used to create threads, holes, and other features.

Milling is a versatile process that can be used to create a variety of parts and components. It is often used to create parts for the automotive, aerospace, and medical industries. It can also be used to create parts for consumer products, such as furniture, appliances, and toys.

Milling can be used to create a variety of features on a workpiece, including slots, grooves, and other complex shapes. It can also be used to create threads, holes, and other features. Milling can also be used to create a variety of finishes on a workpiece, including smooth, textured, and polished surfaces.

Milling can also be used to create a variety of shapes and features on a workpiece, including flat surfaces, curved surfaces, slots, grooves, and other complex shapes. It can also be used to create threads, holes, and other features. Milling can also be used to create a variety of finishes on a workpiece, including smooth, textured, and polished surfaces.

Milling can also be used to create a variety of shapes and features on a workpiece, including flat surfaces, curved surfaces, slots, grooves, and other complex shapes. It can also be used to create threads, holes, and other features. Milling can also be used to create a variety of finishes on a workpiece, including smooth, textured, and polished surfaces.

Milling can also be used to create a variety of shapes and features on a workpiece, including flat surfaces, curved surfaces, slots, grooves, and other complex shapes. It can also be used to create threads, holes, and other features.

What kind of jobs can be done on a milling machine?

A milling machine is a versatile tool used in a variety of industrial and manufacturing settings. It is used to shape and cut materials such as metal, wood, and plastic. It can be used to create a variety of shapes and sizes, and can be used to create complex parts with precise dimensions. Common jobs that can be done on a milling machine include cutting, drilling, boring, reaming, tapping, and threading. It can also be used to create slots, grooves, and contours, as well as to create complex shapes and patterns. Additionally, milling machines can be used to create molds and dies, as well as to create intricate parts for medical and aerospace applications. In addition to these tasks, milling machines can also be used to sharpen tools, create gears, and create intricate parts for jewelry and other decorative items.

Why is milling important?

Milling is an important process in manufacturing as it is used to shape and finish materials such as metals, plastics, and wood. It is a process that uses a rotating cutting tool to remove material from a workpiece in order to create a desired shape or finish. Milling is used in a variety of industries, including automotive, aerospace, medical, and construction.

Milling is important because it is a precise and efficient way to shape and finish materials. It is a subtractive process, meaning that material is removed from the workpiece in order to create the desired shape or finish. This is in contrast to additive processes, such as 3D printing, which add material to the workpiece in order to create the desired shape or finish. Milling is also a versatile process, as it can be used to create a variety of shapes and finishes.

Milling is also important because it is a relatively fast process. It is much faster than other processes such as grinding, which can take much longer to complete.

What features can milling produce?

Milling is a machining process that uses a rotating cutting tool to shape and form materials such as metal, wood, and plastic. It is a versatile process that can produce a wide variety of features on a workpiece. Common features that can be produced with milling include slots, grooves, pockets, contours, threads, and flat surfaces.

Slots are linear cuts that can be straight, curved, or angled. They can be used to create a variety of shapes and sizes, and can be used to create a variety of features such as keyways, splines, and tapers. Grooves are similar to slots, but are typically curved or angled. They can be used to create a variety of shapes and sizes, and can be used to create a variety of features such as splines, keyways, and tapers.

How many types of milling are there?

Milling is a machining process that uses a rotating cutting tool to shape and form materials such as metal, wood, and plastic. It is one of the most commonly used processes in manufacturing and is used to create a variety of shapes and sizes. There are several different types of milling, each of which has its own unique characteristics and applications.

The most common type of milling is end milling, which is used to create flat surfaces, slots, and contours. This type of milling is done with a rotating end mill, which is a cutting tool with multiple cutting edges. End milling is used to create a variety of shapes, including slots, grooves, and pockets.

Face milling is another type of milling that is used to create flat surfaces. This type of milling is done with a rotating face mill, which is a cutting tool with multiple cutting edges. Face milling is used to create a variety of shapes, including flat surfaces, slots, and pockets.