CNC (Computer Numerical Control) machines are automated machines that are used to produce parts and components with high precision and repeatability. They are typically used in manufacturing, engineering, and other industrial applications. CNC machines are programmed using a computer-aided design (CAD) software, which allows the user to create a 3D model of the part or component that needs to be produced. The CAD software then generates a set of instructions, known as G-code, which is used to control the CNC machine.

CNC machines are typically used to produce parts and components with high accuracy and repeatability. They are capable of producing parts with tight tolerances and complex geometries. CNC machines are also capable of producing parts with a high degree of surface finish. CNC machines are also capable of producing parts with a high degree of automation, which reduces the need for manual labor and increases production efficiency.

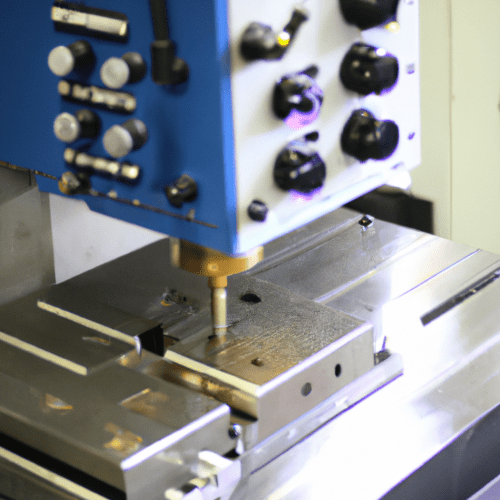

CNC machines are typically composed of several components, including a controller, a spindle, a tool changer, and a worktable.

What is the most common type of CNC machine?

The most common type of CNC machine is a milling machine. CNC milling machines use computer numerical control (CNC) to control the motion of the machine’s cutting tools. They are typically used to create parts with complex shapes and features, such as those found in the automotive, aerospace, and electronics industries. CNC milling machines can be used to cut a variety of materials, including metals, plastics, and composites. They are also used to create molds and dies for injection molding and die casting. CNC milling machines are available in a variety of sizes and configurations, and can be used for a variety of applications.

What is CNC standard?

CNC (Computer Numerical Control) is a manufacturing process that uses computer-controlled machines to produce parts and components with a high degree of accuracy and repeatability. CNC machines are programmed with a set of instructions that tell the machine how to move and what operations to perform. The instructions are written in a language called G-code, which is a standard language used by CNC machines. CNC machines can be used to produce a wide variety of parts and components, from simple to complex.

CNC machines are used in a variety of industries, including automotive, aerospace, medical, and consumer products. CNC machines are used to produce parts for cars, airplanes, medical devices, and consumer products. CNC machines are also used to produce parts for industrial machinery, such as pumps, valves, and other components.

CNC machines are highly accurate and repeatable, and they can produce parts with a high degree of precision. CNC machines are also very efficient, as they can produce parts quickly and with minimal waste.

What all can a CNC machine do?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. CNC machines are used to create precision parts and components from a variety of materials, including metal, plastic, wood, and composites. CNC machines are used in a wide range of industries, including aerospace, automotive, medical, and consumer products.

CNC machines are capable of performing a variety of tasks, including cutting, drilling, milling, grinding, and turning. They can also be used to create complex shapes and patterns, as well as to create intricate details on parts and components. CNC machines are also capable of performing a variety of finishing operations, such as polishing, sanding, and painting.

CNC machines are highly accurate and can produce parts and components with tight tolerances. They are also capable of producing parts and components with a high degree of repeatability, meaning that the same part can be produced multiple times with the same results.

Are small CNC machines worth it?

Whether or not a small CNC machine is worth it depends on a variety of factors, such as the intended use, the budget, and the user’s experience level. Small CNC machines are typically less expensive than larger machines, making them a great option for those on a budget. They are also easier to use and require less space, making them ideal for hobbyists and those with limited experience. However, they are not as powerful as larger machines and may not be able to handle more complex projects. Additionally, they may not be able to produce the same level of precision as larger machines.

Ultimately, the decision of whether or not a small CNC machine is worth it depends on the individual’s needs and preferences. If the user is looking for a machine that is affordable, easy to use, and requires minimal space, then a small CNC machine may be the right choice. However, if the user is looking for a machine that can handle more complex projects and produce higher levels of precision, then a larger machine may be the better option.

What do you look for in a CNC lathe?

When looking for a CNC lathe, there are several factors to consider. First, you should consider the size of the lathe. This will depend on the size of the parts you are machining and the amount of space you have available. You should also consider the type of material you will be machining. Different materials require different cutting tools and speeds, so you should make sure the lathe you choose is capable of machining the materials you need. Additionally, you should consider the type of control system the lathe has. Some CNC lathes are operated manually, while others are operated with a computer numerical control (CNC) system. CNC systems allow for more precise and automated machining, so if you need a high level of accuracy, you should look for a CNC lathe. Finally, you should consider the cost of the lathe. CNC lathes can be expensive, so you should make sure you are getting the best value for your money.

How do I choose a machining tool?

Choosing the right machining tool for a particular job is an important decision that can have a significant impact on the quality and cost of the finished product. The first step in selecting the right tool is to understand the job requirements. Consider the material to be machined, the size and shape of the part, the desired surface finish, and the accuracy and tolerances required. Once these parameters are established, the next step is to determine the type of machining process that will be used. This will determine the type of tool that is needed. For example, a milling machine requires a different type of tool than a lathe.

Once the type of machining process is determined, the next step is to select the tool material. Common tool materials include high-speed steel, carbide, and ceramics. Each material has its own advantages and disadvantages, so it is important to consider the application and the desired performance. For example, high-speed steel is a good choice for general-purpose machining, while carbide is better suited for high-performance applications.

Are all CNC machines the same?

No, all CNC machines are not the same. CNC stands for Computer Numerical Control, and it is a type of automation technology used to control machine tools. CNC machines come in a variety of shapes and sizes, and they can be used for a variety of different tasks. Depending on the type of CNC machine, it can be used for cutting, drilling, milling, grinding, and other machining operations. CNC machines can also be used for 3D printing, laser cutting, and other specialized tasks.

The type of CNC machine used will depend on the type of task it is being used for. For example, a CNC milling machine is used for cutting and shaping metal, while a CNC lathe is used for turning and shaping metal. CNC routers are used for cutting and shaping wood, plastic, and other materials. CNC plasma cutters are used for cutting metal, while CNC laser cutters are used for cutting and engraving a variety of materials.