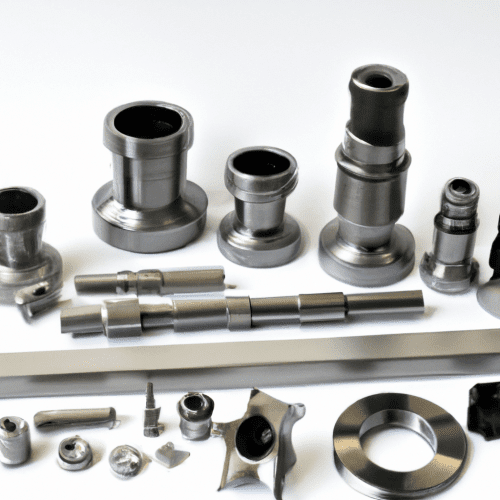

CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape and cut materials into a desired shape or size. The components used in CNC machining include:

- CNC Machine: This is the main component of CNC machining and is used to control the cutting and shaping of the material. It consists of a computer, motors, and other components that are used to control the machine.

- Cutting Tools: These are the tools used to cut and shape the material. They can be made from a variety of materials such as carbide, high-speed steel, and diamond.

- Workpiece: This is the material that is being cut and shaped. It can be made from a variety of materials such as metal, plastic, wood, and composites.

- CAD/CAM Software: This is the software used to create the design for the CNC machine. It is used to create the code that will be used to control the machine.

- Fixtures: These are used to hold the workpiece in place while it is being cut and shaped. They can be made from a variety of materials such as aluminum, steel, and plastic.

- Coolant: This is used to cool the cutting tools and workpiece during the machining process. It can be made from a variety of materials such as water, oil, and air.

What type of motors are used in CNC machining?

The type of motor used in CNC machining depends on the type of CNC machine being used. Generally, stepper motors are used in CNC mills and lathes, while servo motors are used in CNC routers. Stepper motors are used because they are reliable and accurate, and they can be used to precisely control the speed and position of the machine. Servo motors are used in CNC routers because they are more powerful and can handle higher speeds and heavier loads. Both types of motors are typically controlled by a computer, which sends signals to the motor to control its speed and position.

What type of control systems are used in CNC machining?

CNC (Computer Numerical Control) machining uses a variety of control systems to control the motion of the machine and the cutting tools. The most common type of control system used in CNC machining is the G-code control system. G-code is a programming language that is used to control the motion of the machine and the cutting tools. It is a numerical control language that is used to control the motion of the machine and the cutting tools. Other types of control systems used in CNC machining include the PLC (Programmable Logic Controller) and the CAM (Computer Aided Manufacturing) systems. The PLC is a type of control system that is used to control the motion of the machine and the cutting tools. The CAM system is a type of control system that is used to control the cutting tools and the motion of the machine.

What type of cutting tools are used in CNC machining?

CNC machining typically uses a variety of cutting tools, including end mills, drills, reamers, taps, and countersinks. End mills are the most common type of cutting tool used in CNC machining and are used to cut a variety of materials, including aluminum, steel, and plastic. Drills are used to create holes in materials, while reamers are used to enlarge existing holes. Taps are used to create threads in materials, and countersinks are used to create a conical shape in the material.

What type of software is used to control CNC machines?

CNC (Computer Numerical Control) machines are controlled by a specialized type of software known as CNC software. This software is used to create and store instructions for the machine, which are then used to control the machine’s movements. CNC software typically includes features such as CAD/CAM (Computer Aided Design/Computer Aided Manufacturing) capabilities, 3D simulation, and G-code programming. Additionally, some CNC software packages include features such as toolpath optimization, collision detection, and automatic tool selection.

What type of sensors are used in CNC machining?

CNC machining typically uses a variety of different sensors to measure and monitor the machining process. These sensors can include linear position sensors, rotary position sensors, force sensors, temperature sensors, and proximity sensors. Linear position sensors measure the linear position of the machine’s axes, while rotary position sensors measure the angular position of the machine’s axes. Force sensors measure the force applied to the machine’s cutting tool, while temperature sensors measure the temperature of the cutting tool and the workpiece. Proximity sensors measure the distance between the cutting tool and the workpiece. These sensors are used to ensure that the machining process is accurate and efficient.

What type of lubricants are used in CNC machining?

The type of lubricant used in CNC machining depends on the type of material being machined and the type of cutting tool being used. Generally, a light mineral oil or a synthetic oil is used for machining aluminum, brass, and other non-ferrous metals. For machining steel, a heavier oil such as a straight mineral oil or a synthetic oil is used. For high-speed machining, a synthetic oil with a high viscosity index is recommended. For machining stainless steel, a synthetic oil with a high sulfur content is recommended. For machining titanium, a synthetic oil with a high chlorine content is recommended. For machining plastics, a synthetic oil with a low chlorine content is recommended.

What type of coolants are used in CNC machining?

The type of coolant used in CNC machining depends on the type of material being machined and the type of cutting tool being used. Generally, water-soluble coolants are used for machining aluminum, brass, and other non-ferrous metals. Oil-based coolants are used for machining ferrous metals such as steel and iron. Synthetic coolants are also used for machining ferrous metals, as they provide better lubrication and cooling than oil-based coolants. In addition, semi-synthetic coolants are used for machining aluminum and other non-ferrous metals, as they provide better lubrication and cooling than water-soluble coolants.

What type of materials are used in CNC machining?

CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape a variety of materials into a desired shape or form. The materials used in CNC machining can range from metals such as aluminum, steel, brass, and titanium, to plastics such as polycarbonate, nylon, and polypropylene. Other materials used in CNC machining include composites, ceramics, and wood. Depending on the application, the material used in CNC machining can vary. For example, aluminum is often used for parts that require high strength and light weight, while plastics are often used for parts that require flexibility and durability.