What is the purpose of a reference list?

A reference list is a list of sources that have been cited in an academic paper or other document. It provides a way for readers to locate the sources that have been used in the paper, and it also serves as a way to give credit to the authors of those sources. The reference list should include all sources that have been cited in the paper, including books, articles, websites, and other sources. It should be organized in a consistent format, such as alphabetical order, and should include all the necessary information for each source, such as the author’s name, title, date of publication, and URL (if applicable).

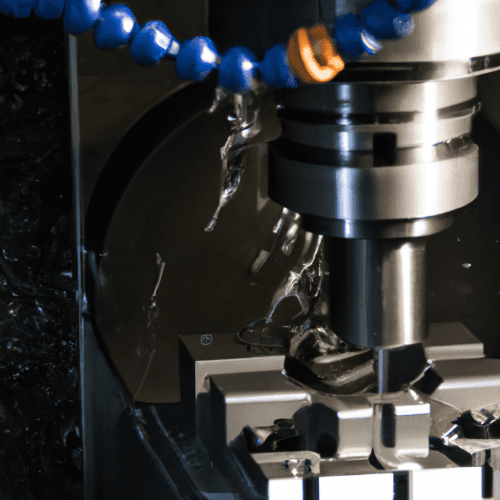

What software is typically used to create a program for CNC machining?

A program for CNC machining is created by a CNC programmer, who is responsible for writing the code that will control the CNC machine. The programmer will use a CAD/CAM software package to create the program, which will include instructions for the machine to follow. The program will include information such as the type of material to be machined, the size and shape of the part, the cutting tools to be used, and the sequence of operations to be performed. Once the program is written, it is tested and verified to ensure that it will produce the desired results. The program is then loaded into the CNC machine, and the machine is ready to begin machining the part.

What are the steps involved in creating a program for CNC machining?

The most common software used to create programs for CNC machining is Computer Aided Design (CAD) software. CAD software is used to create 3D models of the parts that will be machined, which can then be used to generate the CNC program. Popular CAD software for CNC machining includes Autodesk Fusion 360, Solidworks, and CATIA. Additionally, Computer Aided Manufacturing (CAM) software is often used to generate the CNC program from the 3D model. Popular CAM software for CNC machining includes Mastercam, GibbsCAM, and EdgeCAM.

What types of data are typically included in a program for CNC machining?

- Design the program: This involves creating a 3D model of the part to be machined, and then using CAD/CAM software to create the CNC program.

- Select the tooling: This involves selecting the appropriate cutting tools, such as end mills, drills, taps, and reamers, for the job.

- Set up the machine: This involves setting up the CNC machine with the appropriate tooling and workholding devices.

- Load the program: This involves loading the CNC program into the machine’s memory.

- Run the program: This involves running the program and monitoring the machine’s performance.

- Check the results: This involves inspecting the machined part to ensure that it meets the desired specifications.

What is the purpose of a reference list?

A program for CNC machining typically includes a variety of data types, including:

- Geometric data: This includes the shape and size of the part being machined, as well as the tool path and cutting parameters.

- Tool data: This includes the type of tool being used, the cutting speed, feed rate, and other parameters.

- Material data: This includes the type of material being machined, its hardness, and other properties.

- Machine data: This includes the type of machine being used, its speed, and other parameters.

- Process data: This includes the type of process being used, the cutting parameters, and other parameters.

- Program data: This includes the program code, the sequence of operations, and other parameters.

How is a program for CNC machining tested and verified?

The benefits of using a program for CNC machining are numerous.

- Increased Efficiency: CNC machining programs allow for faster and more accurate machining processes, resulting in increased efficiency and productivity. This can lead to shorter lead times and lower costs.

- Improved Quality: CNC machining programs allow for more precise and consistent machining processes, resulting in improved quality and accuracy. This can lead to fewer defects and improved product performance.

- Reduced Waste: CNC machining programs allow for more efficient use of materials, resulting in less waste and lower costs.

- Increased Flexibility: CNC machining programs allow for more flexibility in the machining process, allowing for more complex designs and shapes to be machined.

- Reduced Labor Costs: CNC machining programs allow for fewer operators to be used in the machining process, resulting in reduced labor costs.

- Improved Safety: CNC machining programs allow for safer machining processes, reducing the risk of injury to operators.

What safety protocols should be followed when creating a program for CNC machining?

A program for CNC machining is tested and verified by running a series of tests to ensure that the program is producing the desired results. The tests can include running the program on a CNC machine to check for accuracy, running simulations to check for accuracy, and running a series of tests to check for any errors or inconsistencies in the program. Additionally, the program can be tested and verified by running a series of tests to check for any potential safety issues or hazards that may arise from running the program. Finally, the program can be tested and verified by running a series of tests to check for any potential issues with the CNC machine itself, such as wear and tear, or any other potential problems that may arise from running the program.

What are the most common errors encountered when creating a program for CNC machining?

- Ensure that all personnel involved in the CNC machining process are properly trained and certified in the use of the CNC machine.

- Ensure that all personnel are aware of the safety protocols and procedures for the CNC machining process.

- Ensure that all personnel are wearing the appropriate safety gear, such as safety glasses, gloves, and hearing protection.

- Ensure that all personnel are aware of the potential hazards associated with the CNC machining process, such as flying debris, sparks, and noise.

- Ensure that all personnel are aware of the proper emergency procedures in the event of an accident or injury.

- Ensure that all personnel are aware of the proper maintenance and cleaning procedures for the CNC machine.

- Ensure that all personnel are aware of the proper storage and disposal procedures for any hazardous materials used in the CNC machining process.

- Ensure that all personnel are aware of the proper safety protocols for the disposal of any hazardous waste generated during the CNC machining process.

- Ensure that all personnel are aware of the proper safety protocols for the disposal of any scrap material generated during the CNC machining process.

- Ensure that all personnel are aware of the proper safety protocols for the disposal of any hazardous fumes generated during the CNC machining process.