The cost of a laser cutter can vary greatly depending on the type of laser cutter, its size, and the features it offers. Generally, laser cutters range in price from a few thousand dollars for a small hobbyist laser cutter to hundreds of thousands of dollars for a large industrial laser cutter. Small hobbyist laser cutters are typically priced between $2,000 and $10,000, while industrial laser cutters can cost anywhere from $50,000 to $500,000 or more. The cost of a laser cutter also depends on the type of laser it uses. CO2 laser cutters are the most common type of laser cutter and are typically the most affordable, while fiber laser cutters are more expensive but offer higher precision and faster cutting speeds. Additionally, the cost of a laser cutter can be affected by the type of materials it can cut, the size of the cutting area, the power of the laser, and the features it offers.

How deep can a laser cutter cut?

The depth of cut that a laser cutter can achieve depends on a variety of factors, including the type of material being cut, the power of the laser, and the speed of the cutting process. Generally speaking, a laser cutter can cut through a variety of materials, including wood, acrylic, and metal, with a depth of up to 0.5 inches (1.27 cm). However, this depth can be increased by increasing the power of the laser, or by slowing down the cutting process. For example, a laser cutter with a higher power output can cut through thicker materials, such as steel, with a depth of up to 1 inch (2.54 cm). Additionally, a slower cutting speed can also increase the depth of cut, as it allows the laser to penetrate deeper into the material.

In addition to the power and speed of the laser cutter, the type of material being cut also affects the depth of cut. For example, softer materials, such as wood, can be cut with a greater depth than harder materials, such as steel.

What is the difference between a laser engraver and a laser cutter?

A laser engraver and a laser cutter are both tools that use laser technology to cut or engrave materials. The main difference between the two is the type of material they are used to cut or engrave. A laser engraver is used to engrave or etch designs onto softer materials such as wood, leather, and plastic. A laser cutter is used to cut through harder materials such as metal, glass, and stone. Laser engravers are also used to create intricate designs on softer materials, while laser cutters are used to create precise cuts on harder materials.

The type of laser used in each tool also differs. Laser engravers typically use a CO2 laser, while laser cutters use a fiber laser. The CO2 laser is better suited for engraving softer materials, while the fiber laser is better suited for cutting harder materials.

The speed and accuracy of each tool also differs. Laser engravers are typically slower than laser cutters, but they are more precise and can create intricate designs.

What can you cut with a laser cutter?

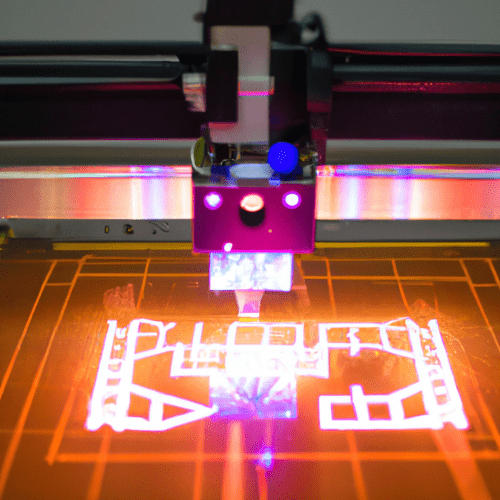

A laser cutter is a powerful tool that can be used to cut a variety of materials. It uses a focused beam of light to cut through materials such as wood, acrylic, paper, fabric, leather, and even metal. The laser cutter is able to cut intricate shapes and patterns with precision and accuracy. It is also capable of engraving and etching designs onto the material.

The laser cutter is a versatile tool that can be used for a variety of projects. It can be used to cut intricate shapes and patterns in wood, acrylic, paper, fabric, leather, and metal. It can also be used to engrave and etch designs onto the material. It is a great tool for creating custom signs, stencils, and other craft projects.

The laser cutter is also capable of cutting through thicker materials such as foam, rubber, and plastic. It can be used to create custom parts for a variety of applications such as robotics, 3D printing, and prototyping. It is also capable of cutting through thicker materials such as aluminum and stainless steel.

How much does a laser metal cutter cost?

The cost of a laser metal cutter can vary greatly depending on the type of machine, its size, and the features it offers. Generally, a small desktop laser cutter can cost anywhere from $4,000 to $8,000, while a larger industrial laser cutter can cost upwards of $100,000. The cost of the laser cutter also depends on the type of laser used, the wattage of the laser, and the type of materials it can cut. For example, a laser cutter with a higher wattage and the ability to cut thicker materials will cost more than one with a lower wattage and the ability to cut thinner materials. Additionally, the cost of the laser cutter may also include the cost of the software, maintenance, and other accessories.

How much is a industrial laser cutter?

The cost of an industrial laser cutter can vary greatly depending on the type of laser cutter, the size of the laser cutter, and the features included. Generally, industrial laser cutters range in price from around $10,000 to over $100,000. Smaller laser cutters, such as those used for hobby or small business applications, may cost around $10,000 to $20,000. Mid-sized laser cutters, such as those used for medium-sized businesses, may cost around $30,000 to $50,000. Large industrial laser cutters, such as those used for large-scale production, may cost around $60,000 to $100,000 or more. Additionally, the cost of an industrial laser cutter may also include the cost of installation, training, and maintenance.

How do I choose a laser cutter?

Choosing a laser cutter can be a daunting task, as there are many different types and models available on the market. The first step in choosing a laser cutter is to determine what type of material you will be cutting. Different laser cutters are designed to cut different materials, so it is important to know what type of material you will be cutting before you start shopping. Once you have determined the type of material you will be cutting, you can begin to narrow down your search.

The next step is to consider the size of the laser cutter you need. Laser cutters come in a variety of sizes, from small desktop models to large industrial models. Consider the size of the material you will be cutting and the size of the projects you will be working on to determine the size of the laser cutter you need.

The power of the laser cutter is also an important factor to consider. The power of the laser cutter will determine how quickly it can cut through the material and how precise the cuts will be.

How much does an industrial laser cost?

The cost of an industrial laser can vary greatly depending on the type of laser, its power, and the features it offers. Generally, industrial lasers can range from a few thousand dollars to hundreds of thousands of dollars. For example, a basic CO2 laser with a power of 10 watts may cost around $3,000, while a more powerful CO2 laser with a power of 100 watts may cost around $50,000. Additionally, industrial lasers with higher power and more features may cost even more. For example, a fiber laser with a power of 1,000 watts may cost around $200,000.

The cost of an industrial laser also depends on the manufacturer and the type of laser. For example, a CO2 laser from a well-known manufacturer may cost more than a CO2 laser from a lesser-known manufacturer. Additionally, the cost of a fiber laser may be higher than the cost of a CO2 laser due to the complexity of the technology.