The cost of a laser cutting machine can vary greatly depending on the type of machine, its size, and the features it offers. Generally, the cost of a laser cutting machine can range from a few thousand dollars for a small desktop machine to hundreds of thousands of dollars for a large industrial machine. The cost of the machine also depends on the type of laser used, the power of the laser, and the type of materials it can cut. For example, a CO2 laser cutting machine is typically more expensive than a fiber laser cutting machine. Additionally, the cost of the machine can be affected by the type of software and automation it offers, as well as the type of maintenance and support it requires. Ultimately, the cost of a laser cutting machine will depend on the specific needs of the user and the type of application it will be used for.

How much does a laser cutter cost?

The cost of a laser cutter can vary greatly depending on the size, power, and features of the machine. Generally, small hobby laser cutters can cost anywhere from $2,000 to $8,000, while industrial-grade laser cutters can cost anywhere from $10,000 to $100,000 or more. The cost of a laser cutter also depends on the type of laser used, the size of the cutting area, the speed of the machine, and the materials it can cut. For example, a laser cutter with a larger cutting area and higher power will cost more than one with a smaller cutting area and lower power. Additionally, laser cutters that can cut a wider variety of materials, such as wood, metal, and plastic, will cost more than those that can only cut one type of material. Finally, laser cutters with faster cutting speeds will cost more than those with slower cutting speeds.

How much does a metal cutting machine cost?

The cost of a metal cutting machine can vary greatly depending on the type of machine, its size, and the features it offers. Generally, a basic metal cutting machine can cost anywhere from a few hundred dollars to several thousand dollars. For example, a small manual metal cutting machine may cost around $200, while a larger, more advanced machine with automated features may cost up to $10,000 or more. The cost of a metal cutting machine also depends on the type of metal it is designed to cut. For example, a machine designed to cut aluminum may cost more than one designed to cut steel. Additionally, the cost of a metal cutting machine may be affected by the brand, the quality of the machine, and the features it offers. For example, a machine with a higher quality build and more advanced features may cost more than a basic machine. Ultimately, the cost of a metal cutting machine will depend on the type of machine, its size, the type of metal it is designed to cut, the brand, the quality, and the features it offers.

How long does a laser cutting machine last?

The longevity of a laser cutting machine depends on a variety of factors, including the type of machine, the quality of the machine, the frequency of use, and the maintenance and care given to the machine. Generally speaking, a laser cutting machine can last anywhere from 10 to 20 years, depending on the aforementioned factors. For example, a high-quality machine that is well-maintained and used regularly can last up to 20 years, while a lower-quality machine that is not well-maintained and used infrequently may only last 10 years. Additionally, the type of machine can also affect its longevity. For example, a CO2 laser cutting machine typically lasts longer than a fiber laser cutting machine. Ultimately, the longevity of a laser cutting machine is determined by the quality of the machine, the frequency of use, and the maintenance and care given to the machine.

How much is laser cutting per hour?

The cost of laser cutting per hour depends on a variety of factors, including the type of material being cut, the complexity of the design, the size of the job, and the type of laser being used. Generally, laser cutting services charge by the hour, with rates ranging from $50 to $150 per hour. For example, a small job with a simple design on a thin material may cost around $50 per hour, while a large job with a complex design on a thick material may cost around $150 per hour. Additionally, some laser cutting services may offer discounts for bulk orders or for repeat customers.

The cost of laser cutting can also vary depending on the type of laser being used. For example, CO2 lasers are typically more expensive than fiber lasers, and the cost of laser cutting can also be affected by the wattage of the laser. Generally, higher wattage lasers are more expensive than lower wattage lasers.

How thick can a laser cutter cut?

The thickness of material that a laser cutter can cut depends on the power of the laser, the material being cut, and the type of laser cutter being used. Generally, laser cutters are capable of cutting through materials up to 1/4 inch thick, although some laser cutters can cut through thicker materials. The power of the laser is the most important factor in determining the thickness of material that can be cut. The higher the power of the laser, the thicker the material that can be cut. The type of laser cutter also affects the thickness of material that can be cut. For example, CO2 laser cutters are capable of cutting through thicker materials than fiber laser cutters. Additionally, the type of material being cut also affects the thickness of material that can be cut. For example, some materials, such as wood, can be cut more easily than other materials, such as metal.

What can you cut with a laser cutter?

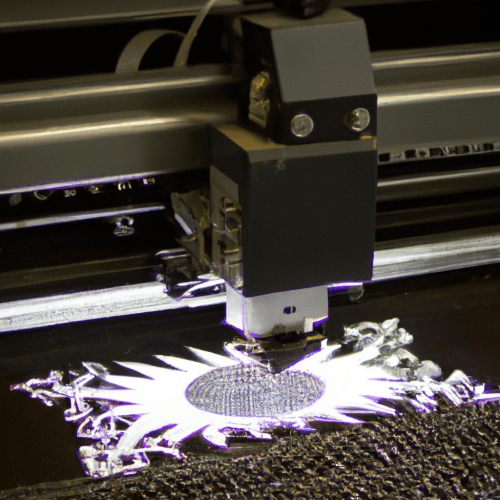

A laser cutter is a powerful tool that can be used to cut a variety of materials. It uses a focused beam of light to cut through materials such as wood, acrylic, paper, fabric, leather, and even metal. The laser cutter is capable of cutting intricate shapes and designs with precision and accuracy.

The laser cutter is most commonly used to cut wood, acrylic, and paper. It can be used to cut intricate shapes and designs in wood, such as furniture, signs, and decorations. It can also be used to cut intricate shapes and designs in acrylic, such as jewelry, awards, and trophies. The laser cutter can also be used to cut intricate shapes and designs in paper, such as cards, invitations, and scrapbooking projects.

The laser cutter can also be used to cut fabric, leather, and even metal. It can be used to cut intricate shapes and designs in fabric, such as clothing, quilts, and upholstery. It can also be used to cut intricate shapes and designs in leather, such as wallets, purses, and belts.

How much does a laser engraver cost?

The cost of a laser engraver can vary greatly depending on the type of machine, its size, and the features it offers. Generally, a basic laser engraver can cost anywhere from $2,000 to $10,000. More advanced models with larger working areas and more features can cost up to $50,000 or more. The cost of the laser engraver also depends on the type of laser used. CO2 lasers are the most common type of laser used in engraving and can cost anywhere from $2,000 to $20,000. Fiber lasers are more expensive and can cost up to $50,000 or more. The cost of the laser engraver also depends on the type of materials it can engrave. Some laser engravers are designed to work with specific materials, such as wood, metal, or plastic, while others are designed to work with a variety of materials. The cost of the laser engraver also depends on the size of the working area.

How much does a steel laser cutter cost?

The cost of a steel laser cutter can vary greatly depending on the size, power, and features of the machine. Generally, a small steel laser cutter with a power of 500W or less can cost anywhere from $5,000 to $20,000. A larger machine with a power of 1,000W or more can cost anywhere from $20,000 to $100,000 or more. The cost of the machine also depends on the type of laser used, the type of cutting bed, and the type of software used to control the machine. Additionally, the cost of the machine can be affected by the cost of the materials used to build the machine, the cost of the maintenance and repair services, and the cost of the consumables such as the laser tubes, mirrors, and lenses.

How much does a Trumpf laser cost?

The cost of a Trumpf laser varies greatly depending on the type of laser, its size, and the features it has. Generally, the cost of a Trumpf laser can range from around $50,000 for a small, basic model to over $1 million for a large, high-end model. The cost of a Trumpf laser also depends on the type of laser, such as a CO2 laser, a fiber laser, or a disk laser. Additionally, the cost of a Trumpf laser can be affected by the features it has, such as the power output, the speed of the laser, and the type of cutting head.

When purchasing a Trumpf laser, it is important to consider the size of the laser, the type of laser, and the features it has. It is also important to consider the cost of the laser, as well as the cost of any additional features or accessories that may be needed. Additionally, it is important to consider the cost of maintenance and repair, as well as the cost of any training that may be required to use the laser.