What is a laser cutting machine?

A laser cutting machine is a type of CNC (Computer Numerical Control) machine that uses a laser beam to cut materials such as metal, plastic, wood, and other materials. The laser beam is generated by a laser source, which is typically a gas laser or a solid-state laser. The laser beam is then focused and directed onto the material to be cut by a set of mirrors and lenses. The laser beam is then used to heat and melt the material, which is then cut by a high-pressure stream of gas, such as nitrogen or oxygen. The laser cutting machine is capable of cutting complex shapes with high precision and accuracy. It is also capable of cutting materials with different thicknesses and materials, making it a versatile tool for many applications.

What can we do with laser cutting machine?

A laser cutting machine is a powerful tool that can be used for a variety of applications. It is a type of CNC (Computer Numerical Control) machine that uses a laser beam to cut materials such as wood, plastic, metal, and even fabric. The laser beam is directed by a computer, which allows for precise and intricate cuts. Laser cutting machines are used in a variety of industries, including automotive, aerospace, medical, and electronics.

One of the most common uses of a laser cutting machine is for cutting and engraving. The laser beam can be used to cut intricate shapes and patterns into a variety of materials, such as wood, plastic, metal, and fabric. The laser beam can also be used to engrave text, logos, and other designs onto the material. This is often used for creating custom signs, awards, and other items.

Another common use of a laser cutting machine is for marking and etching. The laser beam can be used to mark and etch text, logos, and other designs onto a variety of materials.

What is laser cutting process?

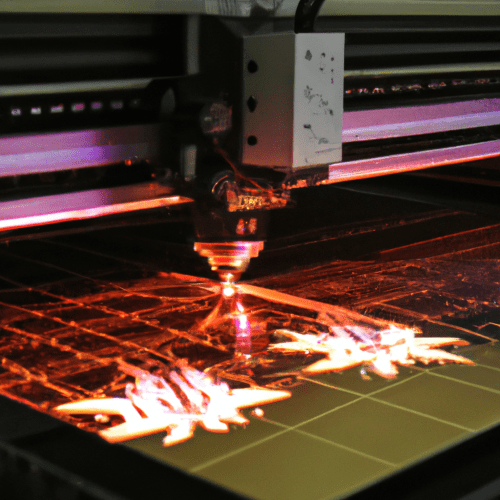

Laser cutting is a process that uses a focused beam of light to cut materials such as wood, metal, plastic, and fabric. The laser beam is generated by a laser source, which is then directed at the material to be cut. The laser beam is focused by a lens or a mirror, and is then directed at the material. The laser beam is then absorbed by the material, causing it to heat up and vaporize. The vaporized material is then blown away by a gas, such as nitrogen or oxygen, leaving a clean cut edge.

The laser cutting process is highly accurate and can be used to cut intricate shapes and patterns. It is also very fast, and can be used to cut large quantities of material in a short amount of time. The laser cutting process is also very versatile, and can be used to cut a variety of materials, including wood, metal, plastic, and fabric.

The laser cutting process is also very cost-effective, as it requires minimal setup and maintenance costs.

Can you make money with a laser cutter?

Yes, you can make money with a laser cutter. Laser cutters are a versatile tool that can be used to create a variety of products, from custom signs and labels to intricate jewelry and artwork. With the right materials and a bit of creativity, you can turn your laser cutter into a profitable business.

The first step to making money with a laser cutter is to determine what type of products you want to create. You can use a laser cutter to create custom signs, labels, and artwork, as well as intricate jewelry and other items. Once you have decided what type of products you want to create, you can start researching the materials and supplies you will need to get started. You will also need to decide on a pricing structure for your products.

Once you have the materials and supplies you need, you can start creating your products. You can use a variety of software programs to design your products, or you can create them from scratch. Once you have designed your products, you can use your laser cutter to cut them out of the materials you have chosen.

What industries use laser cutters?

Laser cutters are used in a variety of industries, including automotive, aerospace, medical, electronics, and manufacturing. In the automotive industry, laser cutters are used to cut and shape metal parts for cars, trucks, and other vehicles. In the aerospace industry, laser cutters are used to cut and shape metal parts for aircraft, spacecraft, and other aerospace components. In the medical industry, laser cutters are used to cut and shape medical implants and prosthetics. In the electronics industry, laser cutters are used to cut and shape circuit boards and other electronic components. In the manufacturing industry, laser cutters are used to cut and shape metal parts for a variety of products, including furniture, appliances, and other consumer goods. Laser cutters are also used in the arts and crafts industry to create intricate designs and patterns in wood, metal, and other materials. Laser cutters are also used in the jewelry industry to cut and shape precious metals and stones.