A finger mill is a type of milling machine used for grinding or pulverizing materials. It is typically used in industrial settings for a variety of applications, including grinding, crushing, and pulverizing materials such as grains, spices, and other food products. The finger mill is composed of a rotating cylinder with a series of blades or fingers that are used to cut, grind, or pulverize the material. The material is fed into the cylinder and the blades or fingers rotate, cutting and grinding the material into a fine powder. The size of the powder can be adjusted by changing the speed of the rotation or the number of blades or fingers. Finger mills are used in a variety of industries, including food processing, pharmaceuticals, and chemical processing. They are also used in the production of animal feed, fertilizers, and other agricultural products. Finger mills are often used to grind or pulverize materials that are too large or too hard to be processed by other types of milling machines.

What is a finger mill?

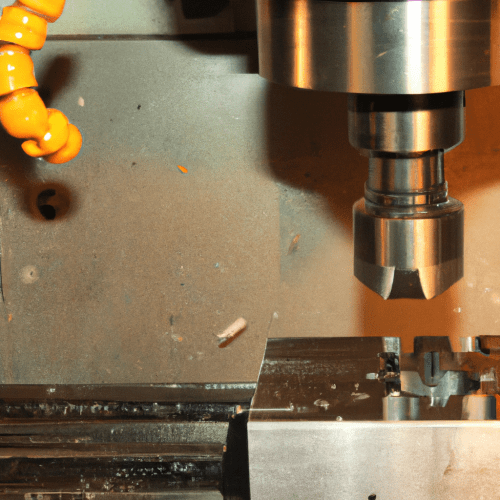

A finger mill is a type of milling machine that is used to shape and form metal and other materials. It is a specialized type of milling machine that uses a rotating cutting tool to shape and form the material. The cutting tool is usually a cylindrical tool with a cutting edge at the end, which is referred to as a finger. The finger mill is used to create intricate shapes and patterns in metal and other materials. It is often used in the production of jewelry, as well as in the production of precision parts for machines and other equipment. The finger mill is a versatile tool that can be used to create a variety of shapes and patterns in metal and other materials. It is also used in the production of medical implants and prosthetics.

What is the purpose of milling?

Milling is a machining process that involves the use of a rotating cutting tool to remove material from a workpiece. The purpose of milling is to shape and finish a workpiece by removing excess material, creating a desired shape, and creating a smooth surface finish. Milling can be used to create a variety of shapes and features, including slots, pockets, contours, and grooves. It can also be used to create complex shapes and features, such as curved surfaces and intricate patterns. Milling can also be used to create a variety of finishes, including a smooth, polished finish, a textured finish, or a matte finish. Milling is a versatile process that can be used to create a variety of components for a variety of applications, including automotive, aerospace, medical, and industrial components.

What are 2 flute end mills used for?

Flute end mills are a type of cutting tool used in milling operations. They are designed with a cutting edge that spirals around the circumference of the tool, allowing them to cut into a variety of materials. They are commonly used for machining operations such as slotting, pocketing, and contouring. They are also used for drilling, reaming, and countersinking.

Flute end mills are typically used for machining operations that require a high degree of precision and accuracy. They are capable of producing intricate shapes and detailed features, making them ideal for creating complex parts. They are also capable of producing smooth finishes, which is why they are often used for finishing operations. Additionally, they are capable of cutting through hard materials, such as stainless steel and titanium, making them a great choice for machining operations that require a high degree of strength and durability.

Which type of machining can be done by milling machine?

Milling machines are a type of machine tool used for machining solid materials such as metal, wood, and plastic. They are capable of cutting and shaping a variety of materials, including metal, wood, plastic, and composites. Milling machines are used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing.

Milling machines are capable of performing a variety of operations, including cutting, drilling, boring, reaming, tapping, and threading. They can also be used to create complex shapes and contours. Milling machines are typically used to produce parts with precise dimensions and shapes. They are also used to create intricate patterns and designs.

Milling machines are capable of performing a variety of operations, including face milling, shoulder milling, end milling, slotting, and contouring. Face milling is used to create flat surfaces on a workpiece. Shoulder milling is used to create a shoulder on a workpiece. End milling is used to create a flat surface on the end of a workpiece.

Which milling machine is used to cut gears?

A milling machine is a versatile tool used for cutting a variety of materials, including metal, wood, and plastic. It is most commonly used to cut gears, as it is capable of producing precise and intricate shapes with a high degree of accuracy. The type of milling machine used to cut gears is typically a gear hobbing machine, which is specifically designed for this purpose.

Gear hobbing machines are equipped with a rotating cutter, known as a hob, which is used to cut the gear teeth. The hob is mounted on a spindle, which is driven by a motor. The spindle is then moved in a linear direction, while the hob is rotated, to cut the gear teeth. The hob is designed to cut the gear teeth at a specific angle, which is determined by the gear’s pitch.

The gear hobbing machine is also equipped with a workpiece holder, which is used to secure the gear in place while it is being cut. The workpiece holder is adjustable, allowing the operator to adjust the position of the gear in relation to the hob.