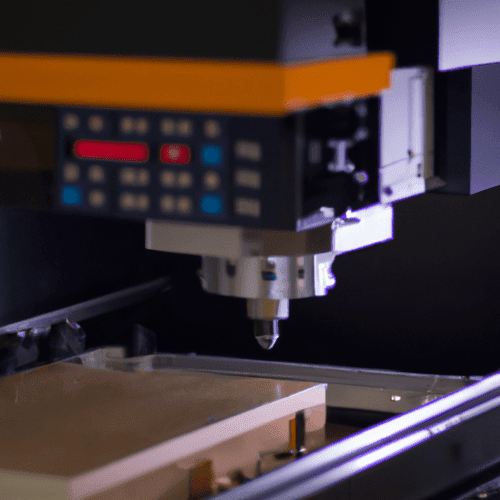

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to remove material from the workpiece, which is then moved in various directions to shape the desired part. Milling machines can be used to perform a variety of operations, including drilling, boring, reaming, tapping, and countersinking. They can also be used to create complex shapes and contours, as well as to cut threads and other features. Milling machines are available in both horizontal and vertical configurations, and can be used for a variety of materials, including wood, plastic, and metal. They are often used in manufacturing, automotive, aerospace, and other industrial applications.

What is milling machine?

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to shape and form the material into a variety of different shapes and sizes. Milling machines can be used to perform a variety of operations, including drilling, boring, reaming, tapping, and threading. They can also be used to create complex shapes and contours, as well as to cut slots and keyways. Milling machines are used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing. They are also used in the production of precision parts and components.

What are the uses of milling machine?

Milling machines are used in a variety of industries for a variety of purposes. They are most commonly used in the manufacturing industry for machining solid materials such as metal and wood. They can also be used to shape plastic and other materials. Milling machines are used to create precise shapes and sizes, as well as to create custom parts for specific applications.

Milling machines are used to cut and shape materials such as metal, wood, and plastic. They are used to create parts with complex shapes and contours, as well as to create flat surfaces. They are also used to create grooves, slots, and other features. Milling machines are used to create a variety of products, including gears, screws, and other components.

Milling machines are also used in the automotive industry to create parts for engines and other components. They are used to create parts with complex shapes and contours, as well as to create flat surfaces. They are also used to create grooves, slots, and other features.

What is milling machine and its types?

A milling machine is a machine tool used for the shaping of metal and other solid materials. Its basic form is that of a rotating cutter or endmill which rotates about the spindle axis (similar to a drill), and a movable table to which the workpiece is affixed. Milling machines are used to cut and shape a variety of materials, including metals (such as steel, aluminum, brass, and iron), wood, and plastic.

There are several different types of milling machines, each with its own unique characteristics and capabilities. The most common types are vertical milling machines, horizontal milling machines, and combination milling machines.

Vertical milling machines are the most common type and feature a vertically oriented spindle that holds and rotates the cutting tool against the workpiece. The cutting tool can be moved up and down, as well as side to side, to create the desired shape.

Horizontal milling machines feature a horizontally oriented spindle that holds and rotates the cutting tool against the workpiece.

What is the difference between a lathe and a milling machine?

A lathe and a milling machine are both used in manufacturing, but they have very different functions. A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, or deformation. It is used to shape metal, wood, or other materials. A milling machine is a machine tool used to machine solid materials. It uses a rotating cutting tool to remove material from the workpiece in a variety of directions. It can be used to drill, bore, cut gears, and produce slots.

The main difference between a lathe and a milling machine is the way in which they cut material. A lathe uses a single-point cutting tool to cut material, while a milling machine uses a multi-point cutting tool to cut material. A lathe is used to shape a workpiece by rotating it against a cutting tool, while a milling machine is used to shape a workpiece by moving the cutting tool across the workpiece in various directions.

What is the process of milling?

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. It is commonly used to create parts with complex shapes and features, such as slots, grooves, and contours. The process of milling begins with the selection of the appropriate cutting tool for the job. This tool is typically a multi-point cutting tool, such as an end mill or a drill bit. The cutting tool is then mounted in a milling machine, which is a machine that holds and rotates the cutting tool.

Once the cutting tool is mounted, the workpiece is then placed in the milling machine and secured in place. The cutting tool is then moved in a specific direction and at a specific speed to begin the cutting process. The cutting tool is typically moved in a linear direction, but can also be moved in a circular pattern. As the cutting tool moves, it removes material from the workpiece in the form of chips. The chips are then collected and disposed of.

What is milling machine in mechanical?

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to remove material from the workpiece, which is then moved in various directions to shape the final product. Milling machines can be used to perform a variety of operations, including drilling, boring, reaming, tapping, and threading. They can also be used to create complex shapes and contours, as well as to cut slots and keyways. Milling machines are used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing. They are also used in the production of precision parts, such as gears, bearings, and other components. Milling machines are available in both horizontal and vertical configurations, and can be used for a variety of operations, including drilling, boring, reaming, tapping, and threading.

What is milling machine Mcq?

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to shape and form the material into a desired shape or size. Milling machines can be used to perform a variety of operations, including drilling, boring, cutting, routing, and grinding. They can also be used to produce complex shapes and contours. Milling machines are used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing. They are also used in the production of precision parts and components.

Milling machines are typically classified according to the number of axes they have. The most common types are vertical milling machines, horizontal milling machines, and combination milling machines. Vertical milling machines have a vertical spindle that moves the cutting tool up and down. Horizontal milling machines have a horizontal spindle that moves the cutting tool side to side. Combination milling machines have both a vertical and a horizontal spindle, allowing for more complex operations.

What is the difference between milling and drilling?

Milling and drilling are two common machining processes used in manufacturing and production. While both processes involve cutting and removing material from a workpiece, there are some key differences between the two.

Milling is a machining process that uses a rotating multi-point cutting tool to remove material from a workpiece. The cutting tool is moved in a linear or rotary motion, and the workpiece is moved in the opposite direction. Milling is used to create complex shapes and contours, as well as to create flat surfaces and slots. It is also used to create threads and other features.

Drilling is a machining process that uses a rotating cutting tool to create a hole in a workpiece. The cutting tool is moved in a linear motion, and the workpiece is held stationary. Drilling is used to create holes of various sizes and depths, as well as to create threaded holes.

The main difference between milling and drilling is the type of cutting tool used and the motion of the cutting tool.

What are the parts of milling machine?

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically consists of a base, a table that moves in the X, Y, and Z directions, and a spindle that rotates around the Z axis. The spindle is driven by a motor, and can be moved up and down, as well as in and out, to create different shapes and depths. The table can also be moved in the X and Y directions to create different shapes and sizes.

The main parts of a milling machine include the base, the table, the spindle, the motor, the feed mechanism, the cutting tool, and the workpiece. The base is the foundation of the machine and provides support for all the other parts. The table is the part of the machine that moves in the X, Y, and Z directions and is used to hold the workpiece. The spindle is the part of the machine that rotates around the Z axis and is driven by the motor.