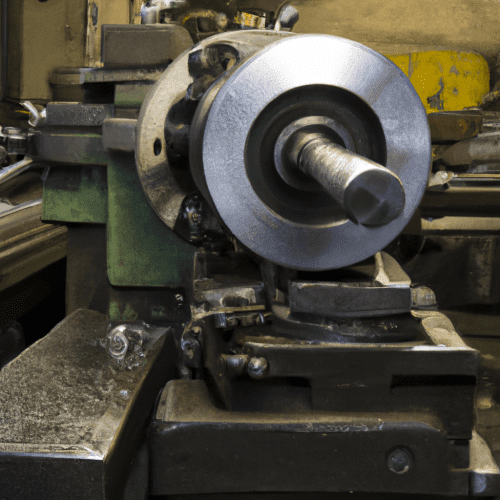

A lathe is a machine tool used to shape and form materials such as metal, wood, and plastic. It is one of the oldest and most versatile machine tools, and is used in a variety of applications, including metalworking, woodworking, and plasticworking. A lathe consists of a bed, a headstock, a tailstock, and a tool rest. The bed is the base of the machine, and the headstock and tailstock are mounted on it. The headstock holds the spindle, which is the rotating part of the machine, and the tailstock holds the cutting tool. The tool rest is used to support the cutting tool.

A teach in lathe is a type of lathe that is designed to be used in a teaching environment. It is typically a smaller, simpler version of a standard lathe, and is designed to be easier to use and understand. It usually has fewer features than a standard lathe, and is often used to teach basic lathe operations. It is also often used to teach more advanced operations, such as threading and drilling.

What are the 3 types of lathe?

The three main types of lathes are engine lathes, turret lathes, and special-purpose lathes.

Engine lathes are the most common type of lathe and are used for general-purpose turning. They are also known as bench lathes, and are used for a variety of operations such as facing, turning, drilling, reaming, and threading. Engine lathes are usually manually operated and are used for small to medium-sized parts.

Turret lathes are similar to engine lathes, but they are equipped with a turret that can hold multiple cutting tools. This allows the operator to quickly change tools and perform multiple operations in one setup. Turret lathes are used for high-volume production and are usually automated.

Special-purpose lathes are designed for specific operations and are used for complex parts. These lathes are usually computer-controlled and can perform multiple operations in one setup. Examples of special-purpose lathes include CNC lathes, Swiss-type lathes, and multi-spindle lathes.

What is the XY and Z on a lathe?

The XY and Z on a lathe refer to the three axes of motion that the cutting tool can move in. The X-axis is the horizontal axis, and is used for moving the cutting tool across the workpiece. The Y-axis is the vertical axis, and is used for moving the cutting tool up and down. The Z-axis is the longitudinal axis, and is used for moving the cutting tool in and out. These three axes of motion are used to create the desired shape of the workpiece.

What is a 3 axis lathe?

A 3 axis lathe is a type of machine tool used for metalworking operations such as turning, drilling, boring, and threading. It is a specialized type of lathe that is designed to work with three axes of motion, which are the X, Y, and Z axes. The X axis is the horizontal axis, the Y axis is the vertical axis, and the Z axis is the rotational axis. The 3 axis lathe is capable of performing a variety of machining operations, including turning, facing, boring, threading, and drilling. It is also capable of performing complex operations such as contouring, grooving, and threading.

The 3 axis lathe is typically used for the production of parts with complex shapes and features. It is capable of producing parts with high precision and accuracy, and is often used in the production of parts for the aerospace, automotive, and medical industries. The 3 axis lathe is also used in the production of parts for the military, as well as for the production of parts for the consumer market.

What is a lathe What are the types of lathe?

A lathe is a machine tool used for shaping and machining metal, wood, and other materials. It is used to turn cylindrical or conical shapes, as well as to cut threads, tapers, and other shapes. Lathes are used in a variety of industries, including automotive, aerospace, and medical.

There are several types of lathes, including engine lathes, turret lathes, and CNC lathes. Engine lathes are the most common type of lathe and are used for general-purpose machining. They are capable of performing a variety of operations, including turning, facing, drilling, and threading. Turret lathes are similar to engine lathes, but they have a turret that can be used to quickly change tools. CNC lathes are computer-controlled and are used for more complex operations. They are capable of performing multiple operations in a single setup, which makes them more efficient than manual lathes.

What are the types of lathe bed?

A lathe bed is the foundation of a lathe machine, and is the most important part of the machine. It is the part that holds the cutting tool and the workpiece in place, and is responsible for providing the necessary support and stability for the machine to function properly. There are several different types of lathe beds, each with its own unique features and advantages.

The most common type of lathe bed is the flat bed. This type of bed is the most basic and is the most common type used in most lathe machines. It is made up of a flat surface, usually made of cast iron, and is designed to provide a stable and level surface for the cutting tool and the workpiece. The flat bed is usually the most economical option, and is the most common type used in most lathe machines.

Another type of lathe bed is the V-bed. This type of bed is designed to provide a more rigid and stable surface for the cutting tool and the workpiece. It is usually made of cast iron and is designed to provide a more rigid and stable surface.