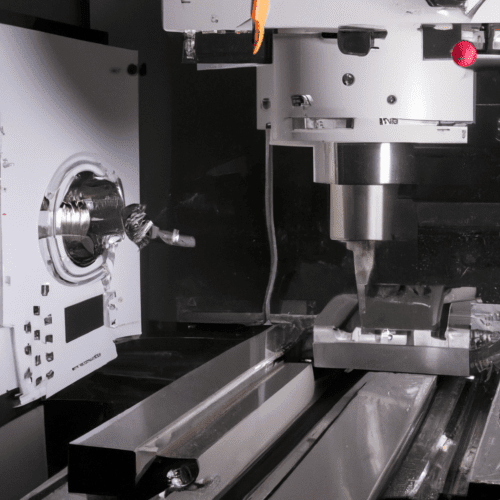

A CNC machine is a computer numerically controlled (CNC) machine that uses a set of instructions to automate the process of machining materials. The instructions are programmed into a computer and sent to the machine, which then controls the motion of the cutting tool to shape the material into the desired shape. CNC machines are used in a variety of industries, from automotive to aerospace to medical. They provide precision and accuracy in the manufacturing process, as well as reduce the need for manual labor. CNC machines can be used for a variety of purposes, including milling, drilling, and cutting of materials. They are also commonly used for 3D printing and engraving. CNC machines are becoming increasingly popular due to their cost-effectiveness and efficiency.

The Benefits of Using a CNC Machine: What You Need to Know

CNC machines are becoming increasingly popular in the manufacturing industry due to their versatility and accuracy. CNC stands for Computer Numerical Control, and is a computer-controlled machining process that is used to create precision parts and components. CNC machines are used in a variety of industries, including automotive, aerospace, medical, and more. The benefits of using a CNC machine are numerous. Since CNC machines are computer-controlled, the process of creating parts and components is highly accurate and consistent. This eliminates the need for manual labor and ensures that parts are manufactured with precision and accuracy. Additionally, CNC machines are able to produce parts with complex shapes and geometries that may not be possible with manual processes. CNC machines are also very efficient since they can process multiple parts in a single cycle. This reduces the amount of time and resources required to manufacture parts and components.

Moreover, CNC machines can produce multiple parts at once, allowing for larger production runs with shorter lead times. CNC machines also require less maintenance than traditional machining processes. This is because they rely on computer-controlled processes that are more reliable and require less regular maintenance. Additionally, CNC machines are able to handle high levels of pressure, making them suitable for use in a range of industrial applications. Finally, CNC machines are incredibly cost-effective. The low cost of production and maintenance makes them a great choice for businesses looking to reduce costs while still producing high-quality parts and components. Overall, the benefits of using a CNC machine are clear. CNC machines offer accuracy, efficiency, reliability, and cost-effectiveness, making them a great choice for businesses looking to streamline their production processes.

Common Uses of CNC Machines: A Comprehensive Guide

CNC machines are computer-controlled tools that are used to cut and shape materials, from metals and plastics to wood and foam. They are used in a wide variety of industries, from automotive and aerospace, to medical and consumer products. CNC machines are highly versatile, and can be used to create a wide range of products with exact precision. CNC machines are used to create prototypes for products, as well as for production runs. Complex parts with intricate details can be created with precision and accuracy, making them ideal for creating custom parts or for large-scale production. CNC machines can be used to create complex curves and shapes, as well as intricate details, such as engravings and cutting patterns. CNC machines are used to cut materials into shapes for industrial and commercial applications. For example, they can be used to cut metal into custom shapes for automotive parts, aerospace parts, and medical devices.

They can also be used to cut plastics and foams into specific shapes for consumer products, such as furniture and toys. CNC machines can also be used to engrave and cut intricate designs into a variety of materials. This process is often used to create custom gifts and awards, as well as for decorative purposes. CNC machines can also be used to cut holes into materials for industrial and commercial applications, such as for air and water pipes. CNC machines can also be used for machining operations, such as drilling and milling. This is a precise process that can be used to cut and shape materials into specific shapes. It is often used to create parts for medical devices, as well as parts for machines and engines. CNC machines are a versatile and powerful tool that can be used to create a variety of products. They are used in virtually every industry, from automotive and aerospace to medical and consumer products, and can produce a range of products with exact precision and accuracy.

An Introduction to CNC Machining: What You Should Know

CNC machining is a manufacturing process used to create components and products with precise dimensions and tight tolerances. It is a process that uses computer-controlled machines to shape and cut materials such as metals, plastics, and composites. CNC machining is widely used across many industries, including automotive, aerospace, medical, and electronics. CNC stands for Computer Numerical Control, which means the machines are directed by a computer program. The program provides instructions in the form of a series of commands, such as coordinates and speed, that are input into the machine. The machine is then able to interpret and follow these instructions to create the desired product. CNC machining is a highly accurate process that produces high-precision parts and components. It is capable of producing intricate shapes and patterns with a high level of accuracy. The process is also faster and more cost-effective than many traditional machining methods.

One of the main advantages of CNC machining is its ability to produce complex shapes that would be difficult to produce by hand or with traditional machining methods. The machines are also able to produce components with very tight tolerances, which is important for many industries. The process can be broken down into three main steps: programming, machining, and inspection. The first step involves programming the machine with the desired dimensions and other specifications. The second step involves the actual machining process, where the machine uses cutting tools to shape and cut the material. The last step involves inspecting the finished product to ensure it meets the desired specifications. CNC machining is a highly versatile and valuable manufacturing process. It is capable of producing components with high precision, intricate shapes, and tight tolerances. It is also cost-effective and efficient, making it a popular choice for many industries.

The History of CNC Machining: How It Has Evolved Over Time

CNC (Computer Numerical Control) machining is a process that has revolutionized the manufacturing industry by allowing for greater precision and accuracy. CNC machining is used to create complex parts and components from a wide range of materials, including plastics, metals, and composites. The history of CNC machining dates back to the 1950s when the first numerical control (NC) machine was invented. This machine used punched tape to record a series of commands, which were then used to control the cutting tool. NC machines quickly replaced manual machining and allowed for greater precision and accuracy in manufacturing. In the late 1960s, the first CNC machine was developed. This machine was able to read and interpret instructions directly from a computer, allowing for further automation and accuracy. CNC machines quickly replaced the NC machines and allowed for even greater precision and accuracy in manufacturing.

Since then, CNC machines have become even more advanced. CNC machines now have the ability to sense and adjust to changes in the material they are cutting, allowing for even greater precision and accuracy. They can also be programmed to produce complex shapes and patterns with ease. CNC machining has come a long way since its invention in the 1950s. It has revolutionized the manufacturing industry by allowing for greater precision and accuracy in producing parts and components. CNC machines have allowed manufacturers to produce complex parts and components with greater speed and accuracy than ever before.

Troubleshooting Common CNC Machine Problems: Tips and Techniques

CNC machines are highly complex pieces of machinery used in various industrial applications. Despite their complexity, they are fairly reliable. Nonetheless, malfunctions do occur, and when they do, it can be challenging to troubleshoot and diagnose the exact cause of the problem. Fortunately, there are some tips and techniques that can help. The first step is to identify the problem. This involves careful observation of the machine’s behavior and sound. If it’s a mechanical issue, it’s likely that the machine will be making a loud noise such as grinding or banging. If it’s a programming issue, the machine may be producing an error message or displaying strange behaviors. Once the problem is identified, the next step is to assess the severity of the issue. If it’s a minor issue, it can often be resolved through troubleshooting. This involves systematically checking and testing the various components of the machine to see if any are malfunctioning or need adjustment.

If the issue is more complex and requires more expertise, it’s best to contact a professional for help. They may be able to provide more technical advice and help diagnose the issue more quickly. Finally, it’s important to take preventative measures to avoid future problems. This includes regularly checking and cleaning the machine, ensuring that it is properly lubricated, and ensuring that all parts are in good working order. It’s also important to keep up with maintenance and regularly update firmware and software. By following these tips and techniques, it’s possible to diagnose and resolve most CNC machine problems. Doing so will help ensure that the machine operates efficiently and effectively.