CNC material refers to any substance or material that can be effectively machined, cut, or shaped using Computer Numerical Control technology. These materials range from metals like aluminum, steel, and brass to plastics, wood, and composites. The choice of CNC material depends on the specific application, desired properties, and manufacturing requirements. Metals are often used for their strength and durability, while plastics offer lightweight and cost-effective solutions. Wood and composites provide unique aesthetic qualities and specialized performance characteristics.

The versatility of CNC machining allows for precise manipulation of these materials, enabling the creation of complex shapes, intricate designs, and high-precision components across various industries including aerospace, automotive, medical, and consumer goods manufacturing. The selection of appropriate CNC materials is crucial for achieving optimal results in terms of functionality, appearance, and cost-effectiveness in the final product.

Most Common Material Used for CNC Tooling

When we discuss CNC, it’s inevitable to talk about the materials compatible with this technology. The material chosen will significantly influence the process, finish, durability, and application of the product.

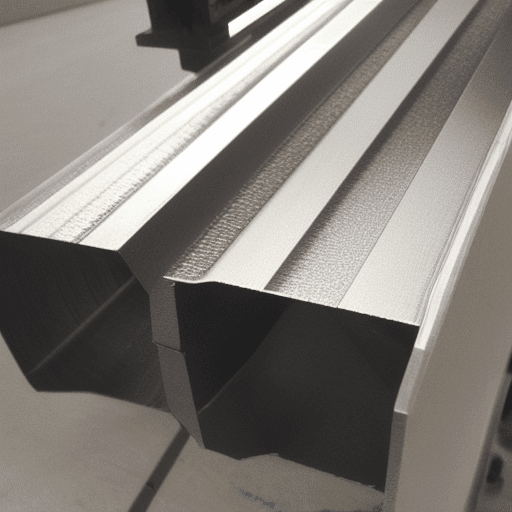

- Aluminum: One of the most popular materials for CNC tooling, aluminum, is favored for its lightweight and strength. Its natural resistance to corrosion and its excellent thermal and electrical conductivity make it a favorite in various industries, including aerospace, automotive, and electronics.

- Brass: This material is often used when a gold-like appearance is desired. It’s easily machined and has decent thermal conductivity. Common uses for CNC-machined brass include musical instruments, decorative items, and electrical connectors.

- Plastics (like ABS, Polycarbonate, and PTFE): Plastics are frequently used for prototyping or when a lighter, corrosion-resistant material is needed. Each plastic has its own unique properties, so the choice between them depends on the application.

- Stainless Steel: Known for its resistance to corrosion and high tensile strength, stainless steel is a common choice for industrial and medical applications.

- Titanium: While more challenging to machine than aluminum, titanium provides a higher strength-to-weight ratio. This makes it ideal for aerospace applications.

- Wood: While not as common as metals or plastics, CNC machines can also be used to carve intricate designs into wood, making it a choice for furniture and decorative items.

CNC in Metal: Precision, Flexibility, and Efficiency

Metalworking has been revolutionized by CNC. The precision, speed, and flexibility offered by CNC machining have allowed metal industries to produce high-quality parts consistently and efficiently.

- Milling: This is perhaps the most common CNC metalworking process. Milling machines use rotary cutting tools to remove material from a workpiece.

- Turning: Here, a cutting tool moves in a linear manner while the workpiece rotates. Lathes, both CNC and conventional, execute the turning process.

- Drilling: CNC drilling involves using multi-point drill bits to produce holes in the metal.

- Electrical Discharge Machining (EDM): This process is used to mold hard metals by sending electrical discharges between the material and an electrode. The electrical sparks produce intense heat, melting and vaporizing a tiny portion of the metal.

- Benefits of CNC in Metal:

- Precision: CNC machines can produce parts with a high degree of accuracy, essential for industries like aerospace and automotive.

- Consistency: Once a design is programmed into a CNC machine, it can produce hundreds, or even thousands, of parts with minimal variance between them.

- Flexibility: Changing a design is as simple as altering the software’s program, making CNC machines highly adaptable.

Best Material for CNC Carving

CNC carving, distinct from typical machining operations, often focuses on intricate designs, detailed patterns, or relief artwork on a material’s surface. Therefore, the best material for CNC carving should not only be easy to machine but should also render a high-quality finish.

- Wood: One of the most traditional materials for carving, wood is widely favored in CNC applications. Its malleability makes it easy to carve intricate designs. Common choices include:

- Hardwood (e.g., oak, maple, walnut) for its durability and beautiful grain.

- Softwood (e.g., pine, cedar) for ease of carving.

- Plastics: Many plastics, such as ABS or polycarbonate, offer smooth carving experiences. They are particularly useful when a lightweight or transparent object is desired.

- Soft Metals: Metals like aluminum and brass are popular choices for CNC carving due to their ability to hold detail well, providing a sophisticated and lasting finish.

Understanding CNC Alloy

An alloy is a mixture of two or more elements, with at least one of them being a metal. In the realm of CNC machining, the term “CNC alloy” usually refers to metals commonly machined using CNC methods, which have been alloyed to enhance certain properties.

- Properties Enhanced by Alloying:

- Strength: Metals can be strengthened by adding other elements. For example, the addition of carbon can make iron into steel.

- Corrosion Resistance: Certain alloys, like stainless steel (an alloy of iron, carbon, and chromium), have enhanced resistance against rust and corrosion.

- Heat Resistance: Some alloys are developed to withstand high temperatures without deforming or melting.

- Common CNC Alloys:

- Aluminum Alloys (e.g., 6061, 7075): Known for their light weight and strength, they’re often used in aerospace and automotive parts.

- Stainless Steel Alloys: Preferred for their corrosion resistance, they’re widely used in food processing, medical, and marine applications.

- Brass Alloys: Often chosen for their machinability and aesthetic appeal.

Materials Used in a Mill

Milling is a versatile CNC operation, and as such, mills can accommodate a broad spectrum of materials, from metals to plastics. Here’s a closer look:

- Metals:

- Aluminum: Easily machinable and lightweight.

- Steel: Both carbon steel and stainless steel are frequently milled. While they are tougher to mill than aluminum, they offer higher strength.

- Brass and Bronze: These are not only machinable but also provide a unique finish.

- Titanium: Strong and lightweight but requires careful milling due to its toughness.

- Plastics:

- ABS: One of the most common plastics milled because of its strength and durability.

- Nylon: Known for its wear resistance and strength.

- Polycarbonate and Acrylic: Often milled when a transparent component is needed.

- Other Materials:

- Wood: From hardwoods to softwoods, mills can handle various wood types.

- Foam: Ideal for lightweight models or prototypes.

- Ceramics: These can be milled but often require specialized milling bits due to their brittleness.

Metals Suitable for CNC Machining

The ability of CNC machines to handle a plethora of metals is one of the reasons they’re so integral to modern manufacturing. Almost all metals can be CNC machined to some extent, but the feasibility and results depend on the metal’s properties and the intended application. Some of the most commonly machined metals include:

- Aluminum: This is a favorite in the CNC world. It’s lightweight, has good thermal and electrical conductivity, and offers a smooth finish. Industries from automotive to aerospace to electronics rely heavily on CNC-machined aluminum parts.

- Steel: Both carbon steel and stainless steel are frequently machined. Carbon steel is known for its strength and versatility, while stainless steel, alloyed with elements like chromium, boasts impressive resistance to corrosion and is often used in medical and food processing industries.

- Brass: This metal is not only aesthetically pleasing but also relatively easy to machine. Its gold-like appearance, combined with its machinability, makes it a choice material for decorative items, instruments, and certain electrical components.

- Titanium: Renowned for its high strength-to-weight ratio, titanium is challenging to machine but is crucial in industries that require durable yet lightweight components, such as aerospace.

- Copper: Although softer and less frequently machined than the others, copper is essential for electrical components due to its exceptional electrical conductivity.

The Significance of CNC

CNC technology has reshaped the landscape of manufacturing, and its importance cannot be overstated. Here’s why:

- Precision: CNC machines are known for their exactness. They can produce components with tight tolerances, ensuring parts fit and function as intended.

- Consistency: Replicating a design hundreds or thousands of times over with minimal variation is a forte of CNC machines. This consistency ensures every part meets the required standards and specifications.

- Efficiency: CNC machines can operate continuously, 24/7, only requiring pauses for maintenance or tool changes. This capability accelerates production timelines.

- Flexibility: Adapting to design changes or shifting between projects is much simpler with CNC than with manual machining. It often involves just loading a new program.

- Safety: By automating processes, CNC machines reduce the need for direct human intervention, decreasing the chances of workplace injuries.

CNC Machinist: The Human Behind the Machine

While CNC machines are automated, they don’t operate in isolation. A CNC machinist is a skilled professional responsible for setting up, operating, and maintaining CNC machines. These individuals translate computer-designed models into physical objects.

A CNC machinist’s duties extend beyond just loading materials and pressing start. They must have a deep understanding of the materials they work with, the tools required for various operations, and the software guiding the machinery. Their expertise ensures that the machine produces parts correctly, efficiently, and safely. They often troubleshoot issues, make necessary adjustments, and ensure the final product aligns with quality standards.

CNC Sheet Explored

When one mentions a CNC sheet, it could encompass two distinct perspectives. Firstly, a CNC sheet can refer to a flat, thin piece of material that is prepared for CNC processing. This sheet, often made of metal, plastic, or wood, is ready for procedures such as engraving, bending, or cutting. On another note, a CNC sheet can also represent a programmatic document, often a part of Computer-Aided Manufacturing (CAM) software outputs, that outlines the sequences and instructions for the CNC machine to enact. This includes the defined tool paths, tool changes, and various operational parameters.

Delving into CNC Engineering

CNC engineering, a niche within the broader field of mechanical and manufacturing engineering, emphasizes the design, creation, and optimization of processes centered on CNC machinery. The professionals in this sector are adept at crafting parts tailored for CNC machining, selecting the most effective machining tactics, and finetuning production techniques to heighten efficiency and precision. Advanced software tools are often at their disposal, aiding them in constructing digital models with impeccable accuracy and simulating the machining course to foresee and resolve potential complications.

The Strength of CNC Aluminium

Aluminium, when subjected to CNC machining processes, possesses commendable strength. However, this strength isn’t purely an outcome of the CNC process but is innately tied to the specific type of aluminium alloy chosen and any subsequent treatments or finishes it undergoes. As a baseline, CNC machining inherently doesn’t compromise the strength of aluminium. Instead, it shapes and structures it to match designated specifications. The real robustness of CNC aluminium lies in its original alloy formulation and any heat treatments or hardening processes it’s subjected to post-machining.

The Ideal Aluminium for CNC

The realm of aluminium alloys is vast, but only a select few are predominantly chosen for CNC operations, owing to their compatibility with machining processes and the resultant finish and strength they offer:

- 6061 Aluminium: A favorite amongst machinists and engineers, 6061 aluminium stands out due to its exceptional machinability, impressive resistance to corrosion, and overall versatility. It has become a staple in various sectors, from automotive components to electronic housings.

- 7075 Aluminium: Distinguished by its superior strength-to-weight ratio, 7075 aluminium finds its prime application in domains where resilience is non-negotiable. Aerospace components, which demand lightweight materials without compromising on strength, often rely on this particular alloy. However, it’s worth noting that its corrosion resistance doesn’t match up to that of 6061.