A Finger Mill is a type of milling machine that is used to shape and form materials such as wood, metal, and plastic. It is a versatile tool that can be used for a variety of applications, including cutting, drilling, and grinding. The Finger Mill is designed to be used with a variety of materials, including wood, metal, and plastic. It is typically used to create intricate shapes and patterns, as well as to create smooth surfaces.

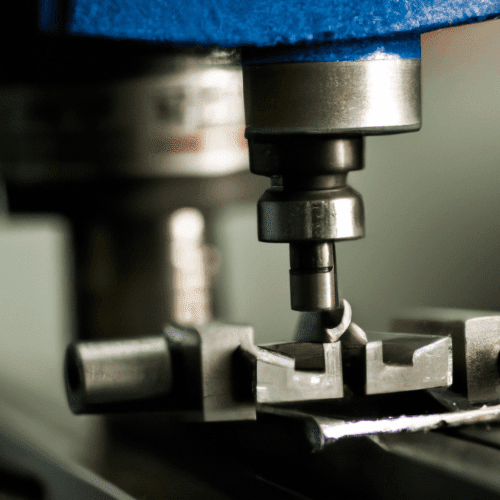

The Finger Mill is composed of a base, a motor, and a cutting head. The base is typically made of metal and is designed to provide a stable platform for the machine. The motor is used to power the cutting head, which is typically made of a high-speed steel or carbide. The cutting head is designed to rotate at high speeds, allowing it to cut through materials quickly and efficiently.

The Finger Mill is used in a variety of industries, including woodworking, metalworking, and plastics manufacturing. It is used to create intricate shapes and patterns, as well as to create smooth surfaces. It is also used to drill holes and to cut through materials. The Finger Mill is a versatile tool that can be used for a variety of applications, making it a valuable tool for any shop.

What can I do with a milling machine?

A milling machine is a versatile tool used in a variety of industrial and manufacturing applications. It is used to shape and cut materials such as metal, wood, and plastic. It can be used to create a variety of shapes and sizes, as well as to drill, bore, and cut into materials. It is also used to create intricate patterns and designs.

Milling machines are used in a variety of industries, including automotive, aerospace, medical, and electronics. They are used to create parts for engines, turbines, and other mechanical components. They are also used to create molds and dies for injection molding and die casting.

Milling machines can be used to create a variety of shapes and sizes, including flat surfaces, curved surfaces, and complex shapes. They can also be used to create intricate patterns and designs. They are used to create parts for engines, turbines, and other mechanical components.

Milling machines can also be used to create molds and dies for injection molding and die casting.

What can you do with a mini milling machine?

A mini milling machine is a versatile tool that can be used for a variety of projects. It is a smaller version of a full-sized milling machine and is typically used for hobbyists or small businesses. With a mini milling machine, you can perform a variety of operations, including drilling, milling, routing, boring, and tapping. You can also use it to create custom parts and components for a variety of projects.

Drilling is one of the most common operations that can be performed with a mini milling machine. It involves using a drill bit to create a hole in a workpiece. The drill bit is held in place by a chuck, which is attached to the spindle of the milling machine. The spindle is then rotated to create the hole. The size of the hole is determined by the size of the drill bit and the speed of the spindle.

Milling is another operation that can be performed with a mini milling machine. It involves using a cutting tool to remove material from a workpiece.

Can you use an endmill in a drill press?

No, you cannot use an endmill in a drill press. An endmill is a type of cutting tool used in milling machines, while a drill press is a type of machine used for drilling holes. Endmills are designed to cut in all directions, while drill presses are designed to only cut in one direction. Endmills are also designed to cut much deeper than drill bits, and the spindle of a drill press is not designed to handle the forces generated by an endmill. Additionally, the spindle of a drill press is not designed to rotate at the speeds necessary for an endmill to cut effectively. For these reasons, it is not recommended to use an endmill in a drill press.

What are mill drills used for?

Mill drills are a type of drill press that are used for a variety of machining operations. They are typically used to drill, bore, ream, countersink, and tap holes in a variety of materials, including metal, wood, and plastic. Mill drills are also used for milling operations, such as cutting slots, grooves, and keyways. They are designed to be more precise than a standard drill press, and are often used in the production of precision parts. Mill drills are available in a variety of sizes and configurations, and can be used for both manual and automated operations. They are typically used in industrial settings, but can also be used in home workshops.

What products are milled?

Milling is a process used to produce a variety of products, including food, pharmaceuticals, and industrial products. Food products that are milled include flour, cornmeal, and other grains. Pharmaceuticals that are milled include active ingredients, excipients, and other components. Industrial products that are milled include plastics, metals, and other materials.

Food products are milled by grinding the grain into a powder. This powder is then used to make flour, cornmeal, and other food products. The grinding process can be done using a variety of methods, including hammer mills, roller mills, and stone mills.

Pharmaceuticals are milled using a variety of methods, including wet milling, dry milling, and micronization. Wet milling involves the use of a liquid to break down the active ingredients into smaller particles. Dry milling involves the use of a mechanical device to break down the active ingredients into smaller particles. Micronization is a process that uses high-pressure air to break down the active ingredients into smaller particles.

Which type of machining can be done by milling machine?

Milling machines are a type of machine tool used for machining solid materials such as metal, wood, and plastic. They are capable of cutting and shaping a variety of materials, including metal, wood, plastic, and composites. Milling machines are used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing.

Milling machines are capable of performing a variety of operations, including cutting, drilling, boring, reaming, tapping, and threading. They can also be used to create complex shapes and contours. Milling machines are typically used to produce parts with precise dimensions and shapes. They are also used to create intricate patterns and designs.

Milling machines are capable of performing a variety of operations, including face milling, shoulder milling, end milling, slotting, and contouring. Face milling is used to create flat surfaces on a workpiece. Shoulder milling is used to create a shoulder on a workpiece. End milling is used to create a flat surface on the end of a workpiece.

What can you do with a Bridgeport milling machine?

A Bridgeport milling machine is a versatile tool used in a variety of industrial and commercial applications. It is a type of vertical milling machine that uses a rotating cutting tool to shape and form materials such as metal, wood, and plastic. The Bridgeport milling machine is capable of performing a wide range of operations, including drilling, boring, reaming, tapping, and milling. It can also be used for cutting, shaping, and forming a variety of materials.

The Bridgeport milling machine is most commonly used for machining metal parts. It can be used to create complex shapes and contours, as well as to drill holes and cut threads. It is also used to create intricate patterns and designs on metal surfaces. The Bridgeport milling machine is also used to create molds and dies for injection molding and die casting.

The Bridgeport milling machine is also used in woodworking applications. It can be used to create intricate patterns and designs on wood surfaces, as well as to cut and shape wood pieces.

What must one do after work is completed on a milling machine?

After completing work on a milling machine, it is important to take the necessary steps to ensure the machine is properly shut down and stored. First, the operator should turn off the power to the machine and unplug it from the power source. Then, the operator should clean the machine, removing any chips or debris that may have accumulated during the machining process. This should be done with a brush or vacuum cleaner. Next, the operator should check the machine for any signs of wear or damage, and make any necessary repairs or adjustments. Finally, the operator should lubricate the machine, using the appropriate lubricant for the type of machine. This will help to ensure the machine runs smoothly and efficiently in the future. Once these steps are completed, the machine should be stored in a safe and secure location, away from any potential hazards.