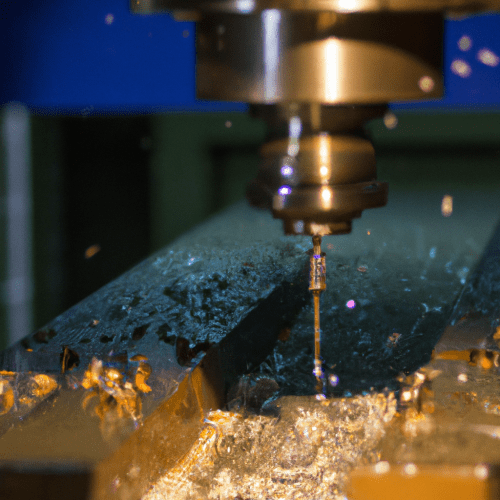

Metal milling is a process used to shape and form solid materials such as metal and other materials. It is typically used to produce parts with complex geometries and features. The process involves the use of a milling machine, which is a machine tool that rotates a cutting tool against a workpiece to remove material. The cutting tool is usually a rotary cutting tool, such as an end mill, which is a type of milling cutter. The milling machine is used to shape the workpiece by cutting away material from the workpiece in a variety of directions. The milling machine can also be used to drill holes, create slots, and create other features on the workpiece. The milling process can be used to create a variety of shapes and features on the workpiece, including flat surfaces, curved surfaces, and complex shapes. The milling process can also be used to create a variety of finishes on the workpiece, including smooth finishes, rough finishes, and textured finishes.

What is milling process metal?

Milling process metal is a process of removing material from a workpiece by using a rotating cutting tool. It is a form of machining, which is the most common form of material removal in metalworking. The cutting tool is usually a milling cutter, which is a rotary cutting tool with multiple cutting edges. The milling process involves the use of a milling machine, which is a machine tool used to shape and form metal and other materials. The milling machine typically consists of a spindle, which rotates the cutting tool, and a table, which is used to hold the workpiece. The cutting tool is moved in a linear direction across the workpiece, removing material in the form of chips. The milling process can be used to create a variety of shapes and features on the workpiece, including slots, pockets, and contours. It can also be used to create complex shapes and features, such as threads and splines. The milling process is used in a variety of industries, including automotive, aerospace, and medical.

What is purpose of milling?

Milling is a machining process that involves the use of a rotating cutting tool to remove material from a workpiece. The purpose of milling is to shape and finish a workpiece by removing excess material, creating a desired shape, and creating a smooth surface finish. Milling can be used to create a variety of shapes and features, including slots, pockets, contours, and grooves. It can also be used to create complex shapes and features, such as curved surfaces and intricate patterns. Milling can also be used to create a variety of finishes, including a smooth, polished finish, a textured finish, or a matte finish. Milling is a versatile process that can be used to create a variety of components for a variety of applications, including automotive, aerospace, medical, and industrial components.

What does a metal milling machine do?

A metal milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to shape and form the material into a variety of different shapes and sizes. Milling machines can be used to perform a variety of operations, including drilling, boring, reaming, tapping, and threading. They can also be used to create complex shapes and contours, as well as to cut slots and keyways. Milling machines are used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing.

Milling machines are typically classified according to the number of axes they have. The most common types are vertical milling machines, which have a spindle that moves in the vertical direction, and horizontal milling machines, which have a spindle that moves in the horizontal direction. The spindle is the part of the machine that holds and rotates the cutting tool. The cutting tool is typically a rotating cutting tool, such as an end mill, drill bit, or router bit.

What is meant by milling process?

Milling is a machining process that involves the use of a rotating multi-point cutting tool to remove material from a workpiece. The cutting tool is moved in a linear direction across the surface of the workpiece, removing material in the form of chips. The cutting tool can be moved in a variety of directions and depths, allowing for the creation of complex shapes and contours. Milling is used in a variety of industries, including automotive, aerospace, medical, and electronics. It is also used to create precision parts for a variety of applications. Milling is a subtractive process, meaning that material is removed from the workpiece in order to create the desired shape. The cutting tool is typically made of high-speed steel or carbide and is held in a spindle that rotates at high speeds. The cutting tool is then moved in a linear direction across the surface of the workpiece, removing material in the form of chips. The cutting tool can be moved in a variety of directions and depths, allowing for the creation of complex shapes and contours.

What is the full meaning of milling?

Milling is a machining process that involves the use of a milling machine to shape and form materials such as metal, wood, or plastic. It is a process that uses a rotating cutting tool to remove material from a workpiece in order to create a desired shape or finish. The milling machine is equipped with a spindle that rotates the cutting tool, and a table that moves the workpiece in the desired direction. The cutting tool is fed into the workpiece at a predetermined depth and angle, and the material is removed in a series of passes. The end result is a finished product with a desired shape and finish. Milling is used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing. It is a versatile process that can be used to create a wide range of products, from simple components to complex parts.

What are the steps of the milling process?

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. The milling process begins with the selection of the appropriate type of milling cutter for the material to be machined. The cutter is then mounted on the spindle of the milling machine and the workpiece is clamped in place.

The next step in the milling process is to set the cutting parameters, such as the feed rate, spindle speed, and depth of cut. The feed rate is the speed at which the cutter is moved across the workpiece, while the spindle speed is the rotational speed of the cutter. The depth of cut is the amount of material that is removed with each pass of the cutter.

Once the cutting parameters have been set, the milling process can begin. The cutter is moved across the workpiece in a series of passes, with each pass removing a small amount of material. The depth of each pass is determined by the depth of cut setting.

What is the difference between milling and drilling?

Milling and drilling are two common machining processes used in manufacturing. Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. The cutting tool is moved in a linear direction across the surface of the workpiece, removing material in the form of small chips. Milling can be used to create a variety of shapes and features on a workpiece, including slots, pockets, and contours.

Drilling is a machining process that uses a rotating cutting tool to create a hole in a workpiece. The cutting tool is moved in a linear direction into the workpiece, creating a hole with a diameter equal to the diameter of the cutting tool. Drilling can be used to create a variety of hole sizes and shapes, including straight, tapered, and countersunk holes.

What is CNC milling process?

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a workpiece in order to create a custom-designed part or product. The process begins with a CAD (Computer Aided Design) drawing of the part or product that is to be created. This drawing is then converted into a set of instructions for the CNC machine, which is programmed to move the cutting tool in a specific pattern and at a specific speed to create the desired shape.

The CNC milling process is typically used to create complex parts with tight tolerances and intricate features. It is also used to create parts with a variety of shapes, including flat surfaces, curved surfaces, and complex 3D shapes. The CNC milling process is highly accurate and can produce parts with a high degree of precision.

What is the meaning of CNC milling?

CNC (Computer Numerical Control) milling is a machining process that uses computer-controlled cutting tools to shape a workpiece. It is a subtractive manufacturing process, meaning that material is removed from the workpiece to create the desired shape. CNC milling machines are programmed with a computer-aided design (CAD) software package, which allows the user to create a virtual model of the desired part. The CNC machine then reads the instructions from the CAD file and uses the cutting tools to shape the workpiece accordingly.

CNC milling is used to create a wide variety of parts, from simple to complex shapes. It is used in the production of parts for the aerospace, automotive, medical, and electronics industries, as well as for prototyping and hobby projects. CNC milling is a precise and efficient process that can produce complex shapes with tight tolerances. It is also a relatively fast process, making it a cost-effective option for many applications.