Milling of wood is a process of cutting and shaping wood into a desired shape or size. It is done using a variety of tools, such as saws, routers, planers, and lathes. The process begins by selecting the type of wood to be milled and then cutting it into the desired shape or size. The wood is then smoothed and finished using sandpaper, chisels, and other tools. The end result is a piece of wood that is ready to be used for a variety of purposes. Milling of wood is an important part of the woodworking process and is used to create furniture, cabinetry, and other wood products.

What is a wood milling machine?

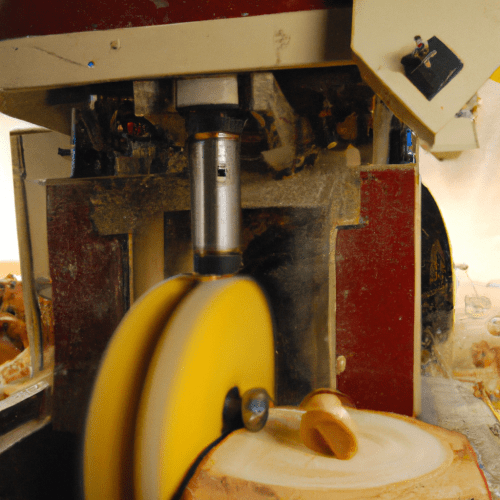

A wood milling machine is a type of machine tool used to shape and finish wood materials. It is typically used to shape and finish wood pieces for furniture, cabinetry, and other woodworking projects. The milling machine uses a rotating cutting tool, such as a drill bit, router bit, or end mill, to shape and finish the wood. The cutting tool is moved along the surface of the wood in a precise pattern to create the desired shape. The milling machine can also be used to cut grooves, slots, and other shapes into the wood. The machine is also used to create decorative edges and patterns on the wood. The milling machine is an essential tool for any woodworker, as it allows them to create precise and intricate shapes and patterns in their woodworking projects.

Why is milling important in woodworking?

Milling is an important process in woodworking because it allows for the precise shaping of wood into a desired form. It is a process that involves cutting away material from a larger piece of wood to create a desired shape or size. Milling is used to create a variety of shapes and sizes, from simple straight cuts to complex curved shapes. It is also used to create a variety of finishes, from smooth surfaces to textured surfaces.

Milling is a process that requires precision and accuracy, and it is important for woodworkers to understand the process in order to achieve the desired results. The process involves the use of a milling machine, which is a machine that uses a rotating cutting tool to cut away material from a larger piece of wood. The cutting tool is usually a router bit, which is a specialized tool designed to cut wood. The router bit is attached to the milling machine and is used to cut away material from the wood.

How do wood mills work?

Wood mills are machines used to process wood into various products. They are typically used to produce lumber, particle board, and other wood-based products. The process begins with the selection of the wood to be used. The wood is then cut into smaller pieces and fed into the mill. Depending on the type of mill, the wood may be cut into planks, boards, or other shapes. The wood is then run through a series of saws, blades, and other cutting tools to shape it into the desired product.

Once the wood is cut, it is then dried and treated to remove any moisture and to protect it from rot and decay. The wood is then sanded to create a smooth surface and to remove any splinters. The wood is then stained or painted to give it a desired color and finish. Finally, the wood is cut into the desired size and shape and packaged for sale.

Can you use wood on a mill?

Yes, you can use wood on a mill. A mill is a machine that is used to shape and cut materials, such as wood, metal, and plastic. It is typically used to create precise shapes and sizes, and can be used to create a variety of products, from furniture to musical instruments.

When using wood on a mill, it is important to select the right type of wood for the job. Different types of wood have different properties, such as hardness, strength, and weight, which can affect the outcome of the project. Softwoods, such as pine and cedar, are often used for projects that require a lot of detail, such as furniture and musical instruments. Hardwoods, such as oak and maple, are better suited for projects that require strength and durability, such as flooring and cabinets.

Once the right type of wood has been selected, it is important to prepare the wood for milling. This includes cutting the wood to the desired size and shape, sanding it to remove any rough edges, and applying a finish to protect the wood from moisture and wear.

Can you CNC mill wood?

Yes, you can CNC mill wood. CNC milling is a machining process that uses computer numerical control (CNC) to control the movement of the cutting tool. It is a subtractive manufacturing process, meaning that material is removed from the workpiece to create the desired shape. CNC milling is used to create a variety of shapes and components from a variety of materials, including wood.

When CNC milling wood, the cutting tool is typically a high-speed steel (HSS) end mill. The end mill is moved along the surface of the wood in a series of passes, removing material in a controlled manner. The cutting tool is guided by the CNC machine, which is programmed with the desired shape and dimensions. The cutting tool is also guided by a cutting fluid, which helps to reduce friction and heat buildup during the milling process.

What is rough lumber?

Rough lumber is lumber that has not been processed or planed. It is lumber that has been cut to size but not sanded, planed, or otherwise finished. Rough lumber is typically used in construction and carpentry projects, and is often referred to as “green” lumber because it has not been dried or treated. It is usually sold in standard sizes, such as 2x4s, 2x6s, and 4x4s, and is usually sold in lengths of 8, 10, 12, and 16 feet. Rough lumber is usually made from softwoods such as pine, fir, and spruce, but can also be made from hardwoods such as oak, maple, and walnut. The rough lumber is usually cut from logs that have been debarked and cut into boards. The boards are then cut to the desired length and width. The rough lumber is then graded according to its strength and appearance. The grading system is based on the number of knots, splits, and other defects in the wood. The higher the grade, the fewer defects the wood has.