Welcome to our article on the key differences between milling and machining. If you’ve ever wondered about the distinctions between these two essential processes in the manufacturing industry, you’ve come to the right place. In this article, we will provide a comprehensive explanation of milling and machining, including their definitions, techniques, and comparative analysis.

Milling and machining are fundamental techniques used in the production of various components and parts. While they share some similarities, such as the use of CNC technology, they have distinct characteristics that set them apart. Understanding these differences is crucial for manufacturers and engineers to make informed decisions regarding which process to utilize for different applications.

In the following sections, we will explore the various aspects of milling and machining, including their processes, techniques, and applications. We will also discuss the differences between milling and turning, milling and drilling, as well as other types of machining.

If you’re looking to enhance your knowledge of milling and machining, as well as gain insights into their comparative analysis, keep reading. By the end of this article, you’ll have a clear understanding of these processes and how they can be applied in different manufacturing scenarios.

Similarities Between Turning and Milling

In the world of subtractive manufacturing, both turning and milling play significant roles. These processes utilize CNC technology and share several similarities. Understanding these shared characteristics can provide valuable insights into their applications and overall effectiveness in machining.

One essential similarity between turning and milling is that they both belong to the realm of subtractive manufacturing. This means that they involve removing material from a workpiece to shape it into a desired form. The CNC (Computer Numerical Control) technology employed in both processes allows for precise and automated control, enhancing efficiency and accuracy. Additionally, turning and milling are commonly used for machining metals and thermoplastics, making them versatile techniques in various industries.

Suitable Materials for Turning and Milling

While turning and milling can process metals and thermoplastics effectively, they are not suitable for certain materials. Rubber, silicone, and ceramic, for example, are not typically compatible with either process due to their unique properties and composition. It is important to consider the material characteristics when determining the appropriate machining method.

Use of Cutting Fluid in Machining

To ensure optimal performance and prolong tool life, cutting fluids are commonly employed in both turning and milling operations. These fluids serve multiple purposes, such as reducing friction, dissipating heat, and improving surface finish. By lubricating the cutting tool and workpiece interface, cutting fluids help mitigate the generation of excessive heat, which can damage the tool and affect the accuracy of the machining process.

Waste in Turning and Milling

Both turning and milling generate waste material in the form of chips. As the cutting tool removes material from the workpiece, these chips are produced as a byproduct. Proper chip management is crucial to maintain a clean and efficient machining environment. Waste disposal and recycling practices should be implemented to minimize environmental impact and ensure a sustainable manufacturing approach.

| Similarities Between Turning and Milling | |

|---|---|

| Both processes belong to the realm of subtractive manufacturing | Both processes utilize CNC technology for precise control |

| Both processes can be used for machining metals and thermoplastics | Both processes require the use of cutting fluid for optimal performance |

| Both processes generate waste material in the form of chips |

Distinctions in CNC Turning

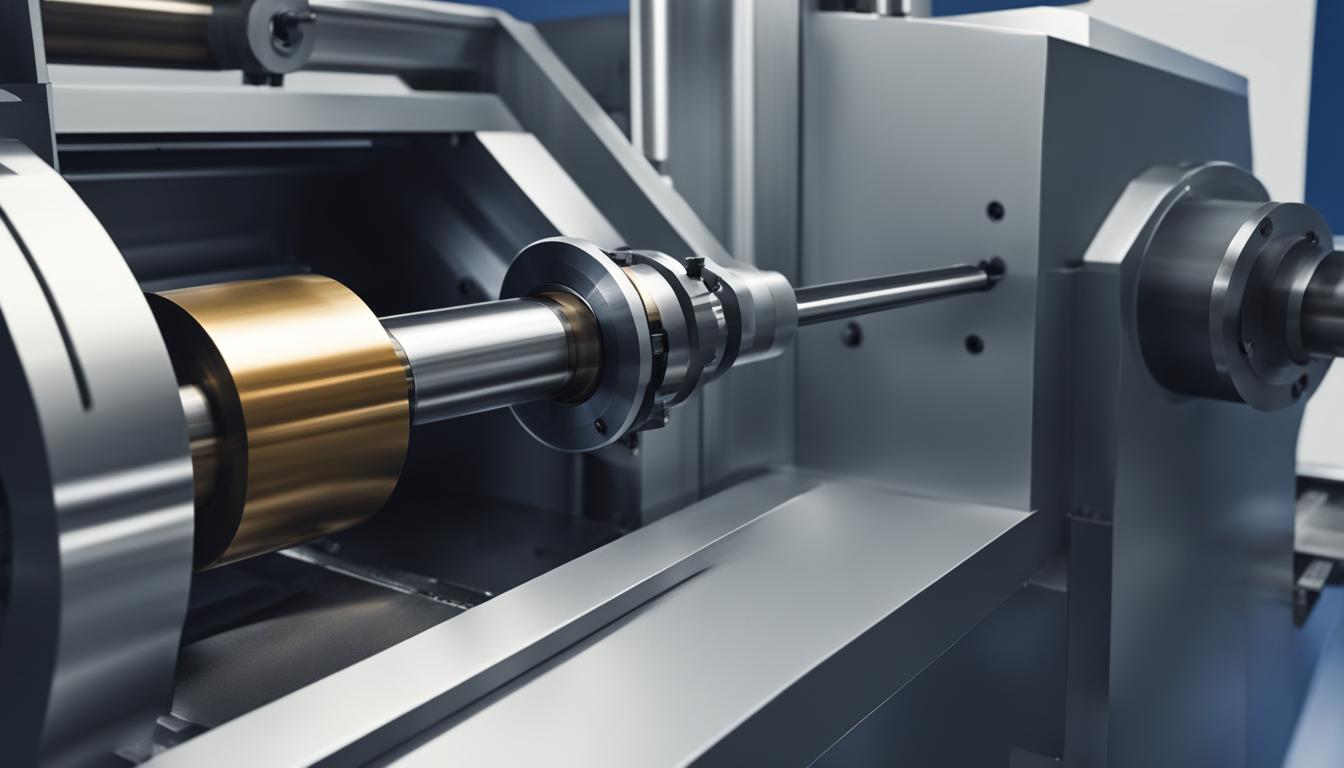

CNC turning is a machining process that involves the use of a chuck and a spindle to create precision components. It offers several distinct features and advantages that make it a popular choice in various industries.

Chuck and Spindle in Turning

In CNC turning, a chuck is used to securely hold round bar stock in place. The chuck is attached to a spindle, which rotates the bar stock at high speeds. This allows for precise cutting and shaping of the material to create the desired part.

Cutting Tools in Turning

In the turning process, a stationary cutting tool is applied to the rotating bar stock to remove material and shape the part. The cutting tool is carefully selected based on the type of material being machined and the desired outcome.

Types of CNC Lathes

CNC turning centers come in various types, depending on the specific requirements of the machining project. These include:

- Single-spindle lathes: These machines have a single spindle and are used for simpler turning operations.

- Main and sub-spindle lathes: These machines feature a main spindle and an additional sub-spindle. They are capable of performing more complex operations and can handle multiple machining tasks simultaneously.

- CNC Swiss turning machines: These machines are designed for high-precision turning and are equipped with “live” tooling. This allows for additional features to be added to the part, such as drilling, milling, and tapping.

Advantages of Turned Parts

Turned parts offer several advantages in terms of efficiency and performance. These include:

- Smaller size: Turned parts are often smaller in size, making them suitable for applications where space is limited.

- Efficiency: CNC turning allows for fast and accurate production, reducing manufacturing time and increasing productivity.

- High quality: The precision and accuracy achieved in CNC turning result in high-quality finished parts with tight tolerances.

- Cost-effective: Turned parts can be produced quickly and with minimal material waste, making them cost-effective for large-scale production.

To illustrate the distinctions in CNC turning, consider the following table:

| Type of CNC Lathe | Key Features |

|---|---|

| Single-spindle lathe | Simple turning operations |

| Main and sub-spindle lathe | Complex turning operations, simultaneous machining tasks |

| CNC Swiss turning machine | High-precision turning, “live” tooling for additional features |

Distinctions in CNC Milling

CNC milling is a versatile machining process that uses a rotating cutting tool to remove material from a stationary workpiece. It offers several distinct advantages and variations compared to other machining techniques. Let’s delve into the key distinctions in CNC milling:

Types of Milling Processes

CNC milling encompasses various processes, each suited for different applications and precision levels. Some common types of milling processes include:

- Face milling

- Peripheral milling

- End milling

- Slot milling

- Drilling

Materials Suitable for Milling

CNC milling can be performed on a wide range of materials, making it highly versatile. Some common materials suitable for milling include:

- Metals (aluminum, steel, titanium, etc.)

- Plastics (ABS, acrylic, nylon, etc.)

- Composites

- Wood

Applications of CNC Milling

CNC milling finds extensive applications across various industries due to its ability to create complex shapes and features. Some notable applications of CNC milling include:

- Aerospace components

- Automotive parts

- Medical devices

- Electronics

- Prototyping

To better understand the distinctions in CNC milling, refer to the table below:

| CNC Milling | Distinct Characteristics |

|---|---|

| Movement | The cutting tool rotates and moves against a stationary workpiece. |

| Capabilities | Produces complex shapes and features using various milling processes. |

| Materials | Suitable for milling metals, plastics, composites, and wood. |

| Applications | Used in aerospace, automotive, medical, electronics, and prototyping industries. |

As you can see, CNC milling offers exceptional versatility and precision, making it an essential manufacturing process for a wide range of industries.

Overview of Turning vs Milling

When it comes to machining processes, turning and milling play vital roles in creating various shapes and surfaces. Understanding the key differences between these two techniques can help manufacturers choose the right method for their specific needs.

Turning involves rotating the workpiece to produce cylindrical or conical shapes, while milling focuses on creating flat or sculptured surfaces. In turning, a lathe machine is used, along with a single point turning tool. On the other hand, milling employs a milling machine equipped with a multi-point cutting tool.

In turning, the cutting tool maintains continuous contact with the workpiece as it removes material. This results in the production of fragmented or continuous chips. In contrast, milling involves intermittent contact between the cutting tool and the workpiece, leading to the generation of discontinuous chips.

In terms of the final result, turning is ideal for producing cylindrical or conical shapes, making it suitable for applications such as creating shafts, pins, and cylinders. In contrast, milling is more effective in producing flat surfaces and complex three-dimensional shapes. This makes it suitable for tasks such as creating gears, slots, and curves.

Both turning and milling processes have their own advantages and applications. Turning is often preferred for its efficiency in creating cylindrical parts, while milling offers greater versatility in shaping different materials and achieving intricate designs.

Overall, the choice between turning and milling depends on the desired outcome, part requirements, and the materials used. Manufacturers must carefully consider factors such as the type of shape or surface needed, the precision required, and the overall efficiency in order to determine which method is best suited for their specific machining needs.

Overview of Turning and Milling

| Aspect | Turning | Milling |

|---|---|---|

| Machine Used | Lathe | Milling Machine |

| Cutting Tool | Single Point Turning Tool | Multi-Point Cutting Tool |

| Contact with Workpiece | Continuous | Intermittent |

| Resulting Shape | Cylindrical or Conical | Flat or Sculptured |

| Chips Produced | Fragmented or Continuous | Discontinuous |

Milled Features on a Turned Part

When it comes to machining capabilities, turning equipment can offer more than just the production of cylindrical shapes. Small milled features can be machined on a turned part, allowing for additional design possibilities and functionality. The ability to incorporate milled features expands the versatility and flexibility of turning equipment.

The feasibility of adding milled features on a turned part depends on factors such as the size, complexity, and material type. By utilizing machining techniques like milling, turned parts can have added features like flats, slots, and pockets. This opens up a wide range of applications for turned parts, enabling manufacturers to meet diverse design requirements.

Adding milled features on turned parts requires precision and expertise. Skilled operators and advanced CNC machinery ensure accurate positioning and alignment for precise milling operations. Manufacturers with proficient machining capabilities can seamlessly integrate milling processes into turning operations, creating complex and functional turned parts.

| Machining Capability | Description |

|---|---|

| Flexibility | Turning equipment can incorporate milled features, providing flexibility in part design and functionality. |

| Enhanced Functionality | Milled features on turned parts can add additional functionality, such as keyways or grooves. |

| Improved Design Possibilities | The ability to incorporate milled features expands design possibilities, allowing for more intricate and complex shapes. |

| Precision Machining | Advanced CNC machinery ensures precise positioning and alignment when machining milled features on turned parts. |

Choosing Between Turning and Milling

When it comes to selecting between turning and milling for your machining needs, there are several factors that can influence your decision. These factors include part design and features, size, complexity of the part, and the material type to be machined.

If you have large, square, or flat parts with intricate features, milling is typically the preferred method. Milling machines have the capability to produce precise flat or sculptured surfaces with great accuracy. It is an ideal choice for parts that require complex shapes and features.

On the other hand, if your parts are cylindrical in shape, turning is the way to go. Turning involves rotating the workpiece against a stationary cutting tool, creating cylindrical or conical shapes. It is commonly used for producing shafts, cylinders, and other cylindrical components.

Let’s take a look at how different factors can influence the decision between turning and milling:

- Part Design and Features: Consider the specific design requirements of your part. If your part has intricate features, such as pockets, slots, or cavities, milling may be the better choice. Turning is more suitable for parts with simpler geometries.

- Size: The size of your part can also play a role in the decision-making process. Milling machines are well-suited for larger parts, while turning is typically used for smaller components.

- Complexity of the Part: If your part has complex shapes or requires high precision, milling is often the preferred method. Milling machines offer more versatility and can handle intricate designs.

- Material Type: The type of material you are working with is another crucial factor. Some materials, such as metals and thermoplastics, can be machined using both turning and milling processes. However, certain materials may be better suited for one method over the other.

By considering these factors and analyzing the specific requirements of your project, you can make an informed decision on whether to choose turning or milling for your machining needs.

| Factors | Turning | Milling |

|---|---|---|

| Part Design and Features | Suitable for simpler geometries | Ideal for intricate features |

| Size | Primarily used for smaller parts | Well-suited for larger parts |

| Complexity of the Part | May be limited in handling complex shapes | Offers versatility for complex designs |

| Material Type | Can handle various materials | Wide range of compatible materials |

Precision Machining Services

When it comes to precision machining services, Pioneer Services is a trusted provider. They offer a range of machining solutions, including CNC Swiss and CNC turning, to meet the needs of various industries and applications.

Pioneer Services’ CNC machines are equipped with advanced technology and capabilities to ensure precise and efficient machining processes. With their state-of-the-art equipment, they can handle parts ranging from 0.145″ to 3.25″ in diameter, providing flexibility in size capabilities.

In addition to turning services, Pioneer Services also has the ability to mill features onto turned parts using their CNC machines. This allows for the creation of complex and precise geometries, enhancing the functionality and aesthetics of the final products.

With their expertise in precision machining and commitment to quality, Pioneer Services delivers reliable and high-quality results. Whether you require CNC Swiss or CNC turning services, they have the capabilities to meet your machining needs.

For more information about Pioneer Services’ precision machining services, visit their website or contact their team of experts.

| Service | Capabilities |

|---|---|

| CNC Swiss | Turning parts with diameters ranging from 0.145″ to 3.25″ |

| CNC Turning | Turning parts with diameters ranging from 0.145″ to 3.25″ |

| Milling Features on Turned Parts | Adding complex geometries to turned parts |

Conclusion

In conclusion, milling and machining are two distinct processes that have different techniques and applications. Turning involves rotating the workpiece, while milling involves rotating the cutting tool. Both processes offer their own advantages and are chosen based on the desired part design and features.

Turning is typically used for cylindrical or conical shapes, while milling is ideal for producing flat or sculptured surfaces. Turning utilizes a lathe and a single point turning tool, whereas milling utilizes a milling machine and a multi-point cutting tool.

Precision machining services, such as those offered by Pioneer Services, provide the capabilities to meet various machining requirements. Their CNC Swiss and CNC turning machines can handle parts ranging from 0.145″ to 3.25″ in diameter, and they also have the ability to mill features onto turned parts. Whether it’s for large, square, or flat parts, or cylindrical parts with features, the choice between turning and milling ultimately depends on factors such as size, complexity, and material type.