Plain milling and side milling are two distinct machining operations that differ in their cutting approach and the surfaces they produce. In plain milling, also known as slab milling, the cutting tool’s axis is parallel to the workpiece surface, and the milling cutter’s periphery performs the cutting action. This method is primarily used to create flat surfaces on the top of the workpiece. Side milling, on the other hand, involves a cutting tool with its axis perpendicular to the workpiece surface, where the side of the cutter engages with the material.

This technique is employed to produce vertical surfaces, slots, or grooves. The choice between plain and side milling depends on the desired outcome, with plain milling excelling at creating large flat surfaces efficiently, while side milling offers precision in creating vertical features and complex profiles. Understanding these differences allows machinists to select the appropriate method for specific manufacturing requirements, optimizing both the quality of the finished product and the efficiency of the machining process.

- Plain milling involves milling a surface parallel to the axis of the cutter.

- Side milling involves milling a surface perpendicular to the axis of the cutter.

- Plain milling is versatile and commonly used for various applications.

- Side milling allows for efficient material removal and precise cuts.

- Choosing the right milling technique depends on factors like material, desired outcome, and tooling capabilities.

Key Characteristics of Plain Milling

Plain milling is a versatile milling technique commonly used in various applications. It is characterized by the cutter axis being parallel to the surface being milled, resulting in precise cutting and excellent surface finish. Some key characteristics of plain milling include:

- Surface parallel: In plain milling, the cutter axis is parallel to the surface being milled, allowing for uniform material removal and smooth cutting.

- Versatile: Plain milling is a highly versatile technique that can be used for creating flat surfaces, slots, grooves, and angular features.

- Common applications: Plain milling is commonly used in industries such as automotive, aerospace, and general manufacturing for tasks like producing keyways, gear teeth, and flat surfaces.

Overall, plain milling offers precise cutting capabilities and is suitable for a wide range of applications where the surface needs to be parallel to the cutter axis. Its versatility makes it a popular choice in many industries.

Example: Plain Milling in Automotive Manufacturing

In the automotive industry, plain milling is frequently used for machining engine blocks, cylinder heads, and other components. For example, when creating a flat surface for mating surfaces or precise alignment, plain milling is essential. It is also used to cut keyways for components like crankshafts and camshafts, ensuring proper fit and function.

| Application | Plain Milling Technique |

|---|---|

| Engine Blocks | Create flat surfaces for mating surfaces |

| Cylinder Heads | Machining the sealing surfaces |

| Crankshafts | Cutting keyways for proper alignment |

Key Characteristics of Side Milling

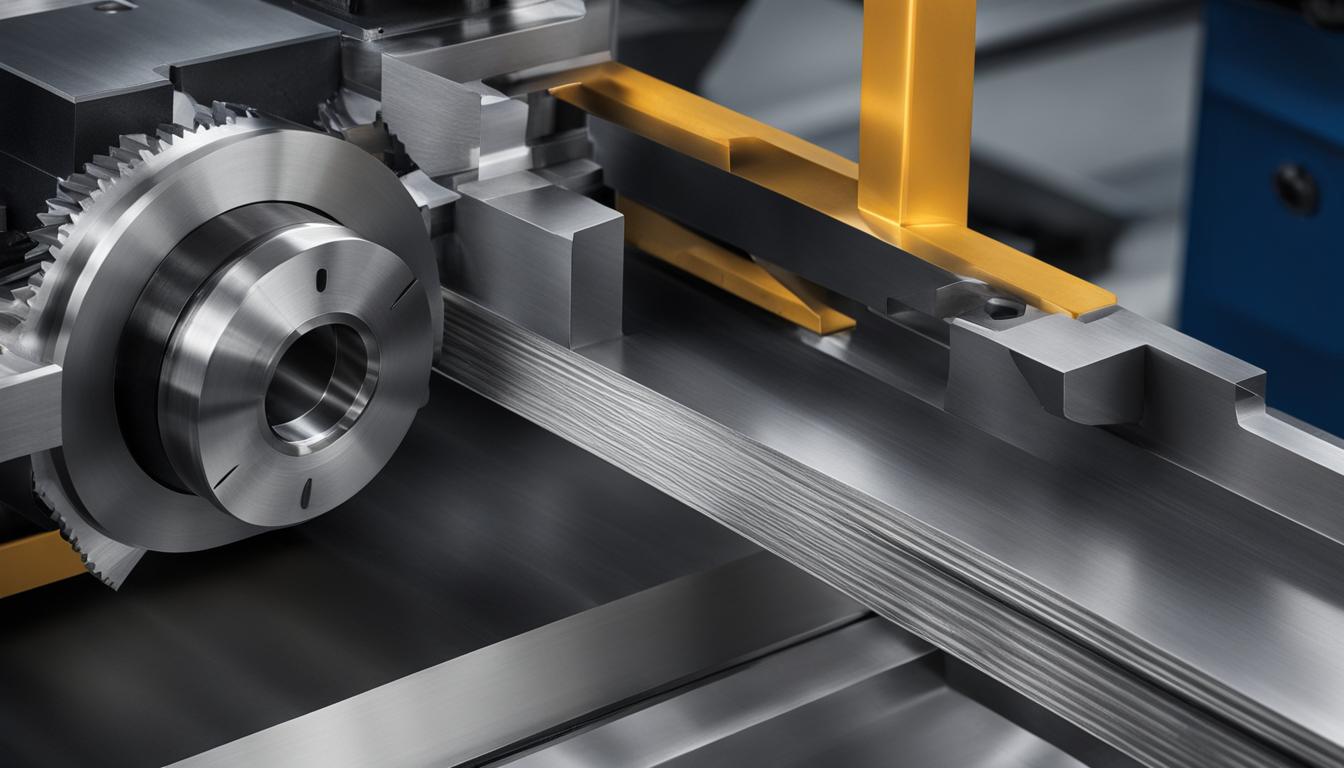

Side milling is a milling technique that offers its own unique set of characteristics and advantages. Unlike plain milling, where the cutter axis is parallel to the surface being milled, side milling involves milling a surface perpendicular to the axis of the cutter. This orientation allows for efficient material removal and precise cuts, making side milling suitable for specific applications.

Efficiency

Side milling is known for its efficiency in material removal. The perpendicular orientation of the cutter axis allows for the removal of larger volumes of material with each pass, reducing the number of passes required for machining. This leads to increased productivity and shorter machining times, making side milling ideal for projects that require fast and efficient material removal.

Precision

Another key characteristic of side milling is its ability to produce precise cuts. The perpendicular orientation of the cutter axis ensures that the cutter engages the workpiece at a 90-degree angle, resulting in precise and accurate machining. This makes side milling suitable for applications where tight tolerances and high precision are required, such as the machining of complex shapes and features.

Specific Applications

Side milling is particularly well-suited for specific applications that require the machining of certain features. For example, side milling is commonly used for creating keyways, which are slots that allow for the insertion of keys to connect rotating machine components. Side milling is also suitable for machining deep slots and pockets, as well as for creating complex shapes and contours on workpieces. These specific applications highlight the versatility and capabilities of side milling in the manufacturing industry.

Differences in Milling Techniques

The main difference between plain milling and side milling lies in the orientation of the cutter axis and the surface being milled. In plain milling, the cutter axis is parallel to the surface, while in side milling, the cutter axis is perpendicular to the surface. This fundamental difference results in variations in the applications of the two techniques. Plain milling is well-suited for creating flat surfaces and angular features, while side milling is ideal for machining complex shapes, deep slots, and keyways.

One of the key differences between plain milling and side milling is the way the cutter engages with the workpiece. In plain milling, the cutter makes contact with the workpiece along the entire length of the cutting edge, resulting in a smoother and more evenly finished surface. On the other hand, in side milling, the cutter engages with the workpiece at the side, allowing for the removal of material in a more efficient and precise manner.

The choice between plain milling and side milling depends on the specific requirements of the milling operation. If the goal is to create flat surfaces or angular features, plain milling is the technique of choice. It is commonly used in applications such as face milling, slab milling, and peripheral milling. On the other hand, if the project requires the machining of complex shapes, deep slots, or keyways, side milling is the preferred technique. It is often used in applications such as slotting, contouring, and pocket milling.

Table: Comparison of Plain Milling and Side Milling Techniques

| Aspect | Plain Milling | Side Milling |

|---|---|---|

| Cutter Axis Orientation | Parallel to the surface | Perpendicular to the surface |

| Surface Finish | Smooth and even | Can be rough depending on the toolpath |

| Material Removal | Along the entire length of the cutting edge | At the side of the cutter |

| Applications | Face milling, slab milling, peripheral milling | Slotting, contouring, pocket milling |

Advantages of Plain Milling

Plain milling offers several advantages that make it a versatile technique suitable for a wide range of milling operations. One of the key advantages of plain milling is its versatility. This technique can be used to create flat surfaces, as well as angular features such as chamfers and bevels. Whether you need to remove material evenly from a surface or create precise geometric shapes, plain milling can deliver the desired results.

Another advantage of plain milling is the surface finish it produces. When performed with the right tools and techniques, plain milling can result in a smooth and high-quality surface finish. This is especially important in industries where aesthetics and precision are crucial, such as automotive and aerospace manufacturing.

The common applications of plain milling further highlight its advantages. This technique is commonly used in the production of keyways, slots, and pockets. It is also frequently employed for creating flat surfaces on workpieces that require efficient material removal. Industries such as metalworking, woodworking, and fabrication rely on plain milling for various machining tasks.

Advantages of Plain Milling:

- Versatile technique for creating flat surfaces and angular features

- Produces smooth and high-quality surface finish

- Commonly used in keyway, slot, and pocket production

- Efficient material removal for workpieces

| Advantages of Plain Milling |

|---|

| Versatile technique for creating flat surfaces and angular features |

| Produces smooth and high-quality surface finish |

| Commonly used in keyway, slot, and pocket production |

| Efficient material removal for workpieces |

Advantages of Side Milling

Side milling offers several advantages that make it a preferred technique in specific milling operations. One of the key advantages of side milling is efficient material removal. The perpendicular orientation of the cutter axis allows for a larger contact area with the workpiece, resulting in faster material removal rates compared to plain milling. This makes side milling an ideal choice when time is a crucial factor in the manufacturing process.

Precise cuts are another benefit of side milling. The perpendicular cutter axis allows for more control and accuracy in cutting operations, resulting in clean and precise edges. This is especially important when machining complex shapes that require intricate details and tight tolerances. Side milling provides the necessary precision to achieve these desired outcomes effectively.

In addition to efficient material removal and precise cuts, side milling is also advantageous for machining complex shapes. The perpendicular orientation of the cutter axis allows for greater versatility in creating intricate contours, curves, and profiles. This makes side milling an excellent technique for applications that involve the production of unique and complex shapes, such as aerospace components or custom tooling.

Choosing the Right Technique for Your Milling Needs

When it comes to milling techniques, choosing the right one is essential for achieving optimal results in your manufacturing process. Several factors need to be considered to ensure you select the most suitable technique for your specific milling needs.

Factors to Consider

1. Material: The type of material you are working with plays a significant role in determining the appropriate milling technique. Certain materials may require the precision and efficiency offered by side milling, while others may be better suited for plain milling.

2. Desired Outcome: Consider the end result you wish to achieve. Are you looking to create flat surfaces or angular features? Plain milling is often the preferred choice for these applications. If your project requires machining complex shapes, deep slots, or keyways, side milling may be the better option.

3. Tooling Capabilities: Assess the capabilities of your milling tools. Some tools may be better suited for specific techniques, while others may offer more versatility. Understanding the strengths and limitations of your tooling will help guide your decision-making process.

By carefully considering these factors, you can make an informed decision and choose the milling technique that will best meet your manufacturing needs. Whether it’s plain milling or side milling, each technique has its own advantages and applications. Selecting the right technique will ensure efficient material removal, precise cuts, and ultimately, the successful completion of your milling operations.

| Factors | Plain Milling | Side Milling |

|---|---|---|

| Orientation of Cutter Axis | Parallel to the surface being milled | Perpendicular to the surface being milled |

| Applications | Create flat surfaces and angular features | Machining complex shapes, deep slots, and keyways |

| Tooling Considerations | Offers versatility | Requires specific tools for efficient operation |

| Precision | May not achieve the same level of precision as side milling | Allows for precise cuts and finer details |

| Material Removal Rate | Slower compared to side milling | Efficient material removal |

Advances in Modern Milling Techniques

In recent years, modern milling techniques have undergone significant advancements, revolutionizing the manufacturing industry. These advancements have led to the development of more efficient, precise, and automated milling processes. Computer numerical control (CNC) milling is one such technique that has gained widespread popularity due to its ability to control the milling process with high accuracy.

With CNC milling, manufacturers can program the milling machines to perform complex operations with minimal human intervention. This not only improves the precision of the milling process but also increases productivity. Additionally, CNC milling allows for the creation of intricate shapes and contours that were previously difficult to achieve using traditional milling methods.

Another notable advancement in modern milling techniques is the emergence of high-speed milling. This technique involves using specialized milling tools and equipment that can operate at significantly higher speeds than conventional milling machines. High-speed milling enables manufacturers to achieve faster material removal rates and reduces machining time, resulting in improved productivity and cost-efficiency.

Automation is also playing a crucial role in modern milling techniques. The integration of robotics and automation systems in milling processes has streamlined operations and improved overall efficiency. Automated milling systems can perform repetitive tasks with consistency and precision, freeing up human operators to focus on more complex operations. This not only reduces the risk of errors but also increases the overall throughput of the milling process.

| Milling Technique | Advancements |

|---|---|

| CNC Milling | High-precision control, complex machining, improved productivity |

| High-Speed Milling | Faster material removal rates, reduced machining time |

| Automation | Robotic integration, increased efficiency, reduced errors |

In conclusion, the advancements in modern milling techniques, including CNC milling, high-speed milling, and automation, have revolutionized the manufacturing industry. These techniques offer higher precision, faster production rates, and improved efficiency, enabling manufacturers to meet the demands of today’s competitive market. By embracing these modern milling techniques, manufacturers can achieve enhanced productivity, cost savings, and superior quality in their milling operations.

Conclusion

Understanding the difference between plain milling and side milling is essential for successful milling operations. Both techniques, plain milling and side milling, have their own advantages and applications in the manufacturing industry. The choice of the right milling technique depends on factors such as the desired outcome, material properties, and tooling capabilities.

For projects requiring flat surfaces or angular features, plain milling is the preferred technique. On the other hand, side milling is ideal for machining complex shapes, deep slots, or keyways. By carefully considering the application requirements and capabilities of each technique, manufacturers can make informed decisions when choosing the appropriate milling method.

Furthermore, modern milling techniques have continued to evolve and offer enhanced precision, speed, and efficiency. Advancements such as computer numerical control (CNC) milling, high-speed milling, and automation have revolutionized the milling process, enabling manufacturers to achieve precise and high-quality results in their operations.

In conclusion, the key to successful milling operations lies in choosing the right technique, whether it be plain milling or side milling, based on the specific requirements of the project. By leveraging the advantages of each technique and utilizing modern milling advancements, manufacturers can optimize their milling processes and achieve superior outcomes.