The invention of the lathe cannot be attributed to a single person, as it evolved over thousands of years. The earliest evidence of a lathe dates back to Ancient Egypt around 1300 BC, with fragments of turned wooden bowls found in Etruscan tombs from the 6th century BC. However, the modern precision metal-cutting lathe, crucial to the Industrial Revolution, was developed by several innovators.

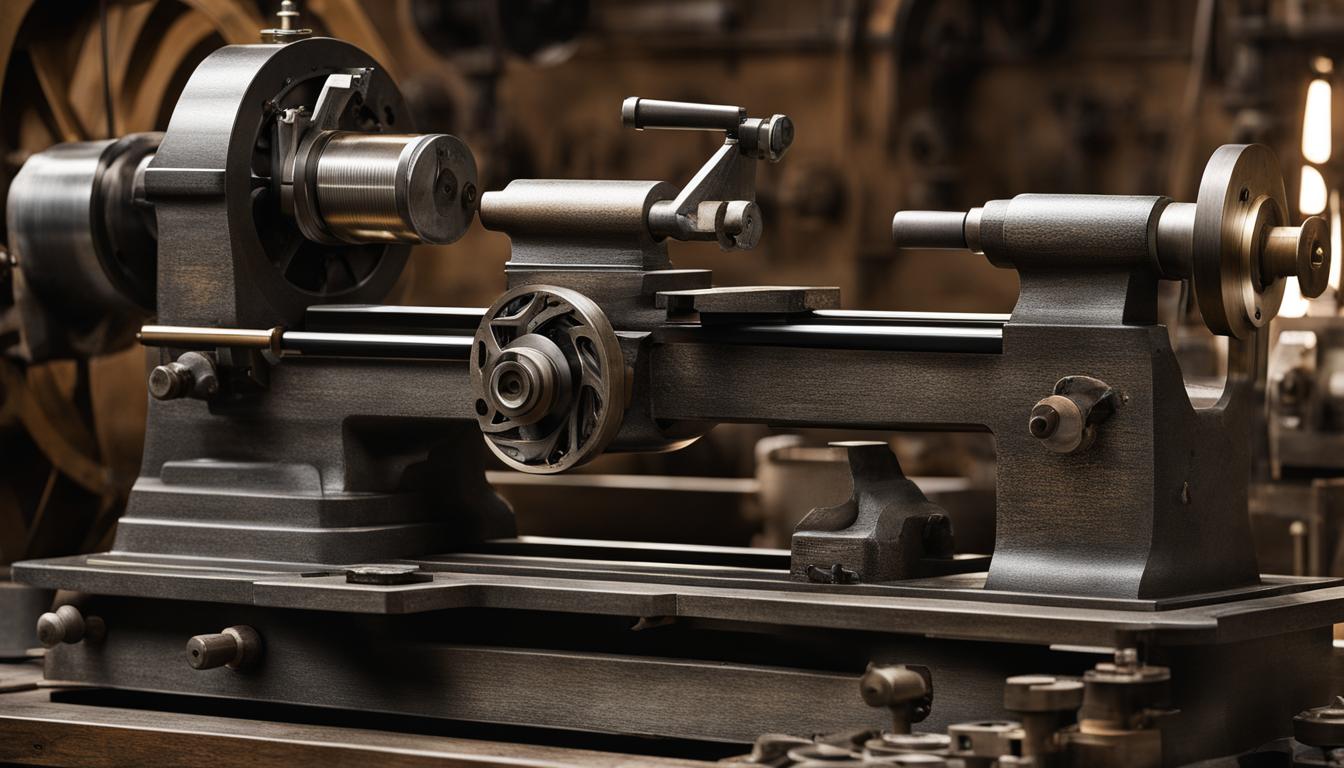

In 1718, Russian engineer Andrey Nartov created a version with a mechanical cutting tool-supporting carriage and gears. A significant advancement came in 1800 when Henry Maudslay, a British engineer, invented the metal lathe with a slide rest. This innovation allowed for precise, standardized cuts and revolutionized manufacturing by enabling the mass production of interchangeable parts. Maudslay’s lathe featured a tool holder clamped into a slide rest, which moved along accurately planed surfaces, controlled by a leadscrew and changeable gears.

This design became the foundation for modern lathes and greatly influenced the development of machine tools. Today, lathes continue to evolve with the integration of computer numerical control (CNC) technology, allowing for even greater precision and automation in manufacturing.

- The lathe was invented in ancient Egypt around 3,000 BC.

- It enabled craftsmen to shape and smooth wood and soft materials.

- Over time, lathe technology has evolved, incorporating advancements such as the introduction of water and wind power, steam power, electrification, and the advent of CNC machines.

- Notable figures in the development of lathe technology include Leonardo da Vinci and Henry Maudslay.

- Lathe machines have had a profound impact on the manufacturing industry, enabling the production of precise and intricate components.

The Origins of Lathe and Its Impact

The lathe, a fundamental tool in machining, has a fascinating history that stretches back to ancient Egypt. Craftsmen in ancient Egypt used a reciprocating bow to spin a workpiece against a cutting tool, allowing them to shape and smooth wood and soft materials. This primitive form of the lathe was the foundation for future advancements in lathe technology.

Ancient Egypt’s invention of the lathe had a profound impact on machining techniques and craftsmanship. It enabled the production of intricate and precise objects, revolutionizing various industries. The lathe’s development over the centuries led to significant advancements in lathe technology, paving the way for the machines we have today.

From the bow lathe of ancient Egypt, lathe technology progressed through the Middle Ages with the introduction of hand-powered lathes. Water and wind power further expanded the capabilities of lathes, allowing for larger and more powerful machines. The industrial revolution saw the emergence of steam-powered lathes, ushering in increased efficiency and production capacity. With the advent of electricity, lathes became more versatile and precise, with the ability to work with a variety of materials.

| Key Milestones in Lathe Technology | Year |

|---|---|

| Bow Lathe | Ancient Egypt |

| Hand-Powered Lathe | Middle Ages |

| Water and Wind Powered Lathe | 18th Century |

| Steam-Powered Lathe | 19th Century |

| Electric Lathe | 19th Century |

The ancient machining techniques of ancient Egypt were crucial in shaping the development of lathe technology. Today, lathe machines continue to play a vital role in various industries, enabling precise manufacturing and the creation of complex components.

The Evolution of Lathe Technology

Lathe technology has come a long way since its humble beginnings in ancient Egypt. Over the centuries, there have been significant advancements that have shaped the development of lathe machines. Let’s explore the key milestones in the evolution of lathe technology and how it has transformed over time.

Hand-Powered Lathe

The first major development in lathe technology was the transition from the reciprocating bow lathe used in ancient Egypt to the hand-powered lathe during the Middle Ages. This new design allowed craftsmen to use a foot pedal to rotate the workpiece, providing better control and precision.

Water and Wind Power

In the Middle Ages, the introduction of water and wind power revolutionized the capabilities of lathes. Water and windmills were used to power larger lathes, enabling the production of larger and more complex objects. This innovation increased efficiency and productivity, marking a significant milestone in lathe technology.

Steam Power and Electrification

The industrial revolution brought about another major leap in lathe technology with the introduction of steam-powered lathes. Steam engines provided a more reliable and powerful source of energy, allowing for higher production capacity. Later, the advent of electrification further improved lathe machines, making them more versatile and precise.

The Rise of CNC Machines

The 1960s saw the emergence of Computer Numerical Control (CNC) machines, revolutionizing the world of lathe technology. CNC lathes are computer-controlled machines that offer unmatched precision, automation, and versatility. They have become indispensable in industries that require high precision and complex machining operations.

Milestones in the Evolution of Lathe Technology

| Time Period | Milestone |

|---|---|

| Ancient Egypt (Around 3,000 BC) | Invention of the reciprocating bow lathe |

| Middle Ages | Transition to the hand-powered lathe |

| Middle Ages | Introduction of water and wind-powered lathes |

| 18th Century | Adoption of steam-powered lathes |

| Late 19th to early 20th centuries | Advancements in electrification for lathes |

| 1960s | Introduction of CNC lathe machines |

Famous Figures in Lathe Technology

Throughout history, the development of lathe technology has involved the contributions of numerous innovators and craftsmen. While the specific inventors of the lathe are not known, there are several notable figures who have made significant advancements in lathe design and techniques. These individuals have played a crucial role in shaping the evolution of lathe machines and their impact on various industries.

One such figure is Leonardo da Vinci, the renowned Italian polymath of the Renaissance period. Da Vinci’s keen interest in engineering and mechanics led him to experiment with lathe design, resulting in significant improvements. His concepts and innovations laid the foundation for future advancements in lathe technology.

Another notable figure in lathe technology is Henry Maudslay, an English engineer known for his contributions to precision engineering and machine tool development. Maudslay’s work in the early 19th century revolutionized the design and construction of lathes, making them more efficient and reliable. His innovations set the standard for lathe manufacturing and had a lasting impact on the industry.

Innovations and Contributions

These famous figures, along with many others, have left a lasting legacy in the field of lathe technology through their innovations and contributions. They have pushed the boundaries of what is possible with lathe machines, enabling the production of intricate and precise components that have revolutionized various industries. Their advancements continue to inspire and drive further innovation in lathe technology, ensuring that it remains an indispensable tool in modern manufacturing.

| Name | Contribution |

|---|---|

| Leonardo da Vinci | Conceptualized and improved lathe design |

| Henry Maudslay | Revolutionized lathe manufacturing and precision engineering |

The Impact of Lathe Technology on Manufacturing

The invention and advancement of lathe technology have had a profound impact on the manufacturing industry. The versatility and capabilities of lathe machines have revolutionized various sectors, including automotive, aerospace, medical, and electronics. With their ability to produce high precision and accurate components, lathe machines play a vital role in the creation of intricate designs and the production of complex objects. This has led to increased efficiency and improved productivity in manufacturing processes.

In the automotive industry, lathe machines are used for machining engine components, such as crankshafts, camshafts, and cylinders, with exceptional precision. In aerospace, lathe machines are employed in the production of turbine blades, airplane parts, and structural components. The medical industry utilizes lathe technology for the manufacturing of orthopedic implants, surgical instruments, and prosthetics. In electronics, lathe machines are crucial for producing precise connectors, switches, and other small components used in electronic devices.

Lathe machines have become indispensable in these sectors due to their ability to meet strict tolerance requirements and deliver consistent quality. They enable manufacturers to produce parts with intricate shapes, smooth surfaces, and tight tolerances, ensuring the functionality and reliability of the final products. By automating processes and offering high precision, lathe machines contribute to reduced manufacturing costs, increased production speed, and improved product quality, allowing manufacturers to stay competitive in the global market.

The Future of Lathe Technology

The future of lathe technology holds exciting possibilities for innovation and advancement. Emerging technologies such as additive manufacturing (3D printing) and nanotechnology have the potential to revolutionize lathe design and techniques. These advancements may enable even greater precision, faster production, and the ability to work with new materials. The integration of artificial intelligence and machine learning also holds promise in optimizing lathe processes and maximizing efficiency.

With the advancements in 3D printing, lathe machines may be able to work in conjunction with additive manufacturing technologies, allowing for the creation of complex geometries and intricate designs with ease. Nanotechnology, on the other hand, may offer the ability to work with materials at the atomic and molecular level, enabling the production of ultra-precise components with unprecedented accuracy.

Artificial intelligence and machine learning have the potential to enhance the capabilities of lathe machines by optimizing tool paths, improving productivity, and reducing errors. These technologies can analyze vast amounts of data and provide real-time feedback and adjustments, leading to more efficient and precise machining processes.

The potential future advancements in lathe technology:

- Integration of 3D printing technology for enhanced design capabilities

- Utilization of nanotechnology for ultra-precise machining

- Integration of artificial intelligence and machine learning for optimized processes

- Improved control systems and programming software in CNC lathe machines

The future of lathe technology is full of possibilities, and as these emerging technologies mature and become more accessible, we can expect to see further advancements in the capabilities and applications of lathe machines. These innovations will continue to drive progress in the manufacturing industry and shape the way we create and manufacture products.

Innovations in CNC Lathe Machines

The continuous advancements in CNC (Computer Numerical Control) lathe technology have revolutionized the manufacturing industry. These highly sophisticated machines offer unmatched precision, automation, and versatility, making them indispensable in various industries. The innovations in CNC lathe machines have paved the way for enhanced productivity, improved efficiency, and expanded capabilities.

Advancements in CNC lathe technology have resulted in improved control systems, enabling operators to have greater command over the machining process. The introduction of enhanced programming software has made it easier to program complex designs and execute intricate machining operations with precision. CNC lathe machines can now perform multi-axis machining, allowing for the creation of intricate and complex geometries in a single setup.

CNC lathe machines find applications in a wide range of industries that require high precision and complex machining operations. In the aerospace industry, CNC lathes are used to manufacture critical components, such as turbine blades and engine parts. They are also extensively used in the automotive industry for the production of engine components, transmission parts, and precision shafts. In the medical field, CNC lathe machines play a crucial role in the production of orthopedic implants, surgical instruments, and medical devices. The versatility and accuracy of CNC lathe machines make them invaluable in these industries and many others.

Advancements in CNC Lathe Technology:

To showcase the advancements in CNC lathe technology, let’s take a look at the following table:

| Advancement | Description |

|---|---|

| Improved Control Systems | Advanced control systems provide operators with greater control and monitoring capabilities, allowing for precise machining operations. |

| Enhanced Programming Software | New programming software enables the creation of complex designs and facilitates the execution of intricate machining operations. |

| Multi-Axis Machining | CNC lathe machines now have the ability to perform multi-axis machining, enabling the creation of intricate and complex geometries in a single setup. |

As CNC lathe technology continues to evolve, we can expect further advancements in areas such as artificial intelligence integration, real-time monitoring and diagnostics, and the use of advanced materials and cutting tools. These innovations will further enhance the capabilities of CNC lathe machines, leading to increased efficiency, reduced cycle times, and improved overall performance.

Legacy of Lathe Technology

Lathe technology has left an indelible mark on the manufacturing industry, shaping its evolution and driving progress. The contributions of lathe machines have been instrumental in enabling the production of intricate and precise components that are essential in various sectors.

One of the key legacies of lathe technology is its impact on industry. The ability to shape and manipulate materials with precision has revolutionized manufacturing processes, leading to increased efficiency and productivity. Lathe machines have played a crucial role in industries such as aerospace, automotive, medical, and electronics, where the demand for high-quality and accurate components is paramount.

The legacy of lathe technology can also be seen in the ongoing advancements and innovations within the field. From the primitive bow lathe of ancient Egypt to the state-of-the-art CNC machines of today, lathe technology continues to evolve. Emerging technologies such as additive manufacturing and nanotechnology hold the potential to further enhance lathe capabilities, enabling even greater precision and the ability to work with new materials.

Contributions to the Industry

Lathe machines have contributed significantly to the growth and development of the manufacturing industry. Some key contributions include:

- Improved Efficiency: The precision and accuracy provided by lathe machines have led to increased efficiency in manufacturing processes. Components produced using lathe machines require minimal post-processing, reducing both time and costs.

- Enhanced Productivity: Lathe machines enable the production of complex and intricate designs with ease. This has resulted in improved productivity, as manufacturers can create intricate components more quickly and in larger quantities.

- Technological Advancements: The development of lathe machines has paved the way for other advancements in manufacturing technology. The principles established by lathe inventors have served as a foundation for the development of other machine tools and automation techniques.

- Skilled Workforce: The utilization of lathe machines in manufacturing has created a demand for skilled machinists who can operate and program these sophisticated machines. This has resulted in the growth of a highly skilled workforce within the industry.

The legacy of lathe technology continues to shape the manufacturing industry, inspiring innovation and driving progress. As technology advances, lathe machines will play a vital role in meeting the evolving demands of modern manufacturing.

Conclusion

The invention of the lathe and its subsequent evolution have had a profound impact on the history of technology and manufacturing. From its origins in ancient Egypt to the sophisticated CNC machines of today, the lathe has revolutionized the way we shape materials and create precise components.

Throughout centuries, lathe technology has advanced, incorporating innovations such as water power, steam power, and electrification. These advancements have increased the efficiency and precision of lathe machines, enabling the production of complex designs and facilitating progress in various industries.

The legacy of lathe technology is evident in the ongoing development of new machining techniques and the integration of emerging technologies. As the future unfolds, technologies like 3D printing, nanotechnology, artificial intelligence, and machine learning offer exciting possibilities for further advancements in lathe design and techniques.

The impact of lathe technology on manufacturing cannot be overstated. Lathe machines play a vital role in industries ranging from automotive and aerospace to medical and electronics. They enable the production of intricate and accurate components, driving progress and innovation in these sectors. Lathe technology continues to shape the manufacturing landscape, meeting the demands of modern industry and driving future advancements.

Acknowledgments

We would like to express our gratitude to the authors, researchers, and historians who have contributed to the study and documentation of lathe technology. Their dedication and expertise have allowed us to delve into the history and impact of lathe machines.

Additional Resources

If you’re looking to delve deeper into the world of lathe technology, there are several valuable resources available that can provide you with further insights and information. Whether you’re a beginner seeking to understand the basics or an experienced professional looking to expand your knowledge, these resources can be invaluable in your journey.

Books

- The History and Development of the Lathe by Eric R. Hansen: This comprehensive book explores the evolution of the lathe, from its ancient origins to modern advancements. It delves into the impact of lathe technology on various industries and provides a detailed account of its historical significance.

- The Modern Manufacturing Lathe: Turning Away from the Past by Brian Greer: This book explores the current state of lathe technology and its role in modern manufacturing. It examines recent innovations in lathe design and techniques, highlighting their impact on industry and the future of manufacturing.

- Lathe: The Tool Information You Need at Your Fingertips by Walter B. Woods: This practical guide offers a comprehensive overview of lathe machines and their applications. It covers everything from basic lathe operation to advanced techniques, making it a valuable resource for both beginners and experienced professionals.

These books provide in-depth knowledge and insights into lathe technology, helping readers gain a deeper understanding of its history, development, and applications.

Additionally, there are numerous online resources, articles, and academic papers available that offer valuable information on lathe technology. These resources can be found through academic databases, industry publications, and online forums dedicated to machining and manufacturing.

Online Resources

- The Machinist’s Blog: This blog provides a wealth of information on lathe technology, including tutorials, tips, and insights from industry experts. It covers various topics related to lathe operation, maintenance, and advanced techniques.

- CNC Zone: This online community is dedicated to CNC machining, including lathe technology. It features forums, articles, and resources where enthusiasts and professionals can exchange knowledge, ask questions, and stay up to date with the latest developments in the field.

- MachiningCloud Resources: MachiningCloud offers a range of resources, including whitepapers, case studies, and technical articles, that cover various aspects of lathe technology. These resources provide valuable insights into best practices, optimization techniques, and emerging trends in the industry.

By exploring these additional resources, you can expand your understanding of lathe technology, stay informed about the latest advancements, and enhance your skills in the field of machining and manufacturing.

Acknowledgments

We would like to express our gratitude to the numerous sources that have contributed to the research and development of this article on lathe technology. The information presented here is a culmination of extensive research, drawing from historical records, scholarly books, insightful articles, and reliable online resources.

Special thanks go to the dedicated authors and researchers who have devoted their time, effort, and expertise to studying and documenting the remarkable history and advancements in lathe technology. Their invaluable contributions have enabled us to present a comprehensive overview that delves into the origins, evolution, impact, and future of lathe machines.

We would also like to acknowledge the support and assistance provided by our team of writers, editors, and content contributors. Their commitment to delivering accurate and engaging content has been instrumental in creating this informative article. Together, we have strived to ensure that the information presented here is relevant, insightful, and meets the needs of our readers.