The principle of turning is a fundamental concept in machining and manufacturing that involves rotating a workpiece while a cutting tool removes material to create cylindrical or conical shapes. This process, typically performed on a lathe, allows for the production of precise, symmetrical parts with various features such as threads, tapers, and contours. The workpiece is secured in a chuck or between centers and rotated at high speeds, while the cutting tool, mounted on a tool post, moves along the axis of rotation or perpendicular to it.

By controlling the speed of rotation, feed rate, and depth of cut, machinists can achieve desired dimensions and surface finishes. Turning is essential in producing a wide range of components, from simple shafts and pins to complex aerospace parts, and is often combined with other machining operations to create intricate designs. The principle of turning also extends to related processes like boring, facing, and threading, making it a versatile and indispensable technique in modern manufacturing.

What is turning explain?

Turning is a machining process used to create cylindrical parts by removing material from a workpiece. It is typically used to create parts with a symmetrical cross-section, such as a cylinder, but it can also be used to create other shapes. The three main movements of turning operations are:

1. Feed: This is the movement of the cutting tool along the length of the workpiece. The feed rate is usually measured in inches per revolution (IPR) or millimeters per revolution (MMPR).

2. Depth of Cut: This is the amount of material that is removed from the workpiece in a single pass. The depth of cut is usually measured in inches or millimeters.

3. Speed: This is the rotational speed of the workpiece. The speed is usually measured in revolutions per minute (RPM).

Turning operations can also involve other movements, such as taper turning, which is the process of creating a tapered surface on the workpiece.

What is lathe write its working principle and explain its various parts with neat?

The lathe’s workpiece is mounted on the spindle, which is driven by an electric motor or other power sources. As the spindle rotates, the cutting tool is brought into contact with the workpiece at a specific angle, depth, and speed, leading to the removal of material and the generation of the desired shape. The cutting tool can be controlled manually, or in advanced lathes, it may be computer numerically controlled (CNC) for precision and automation.

Various Parts of a Lathe:

- Bed: The bed is the main foundation of the lathe, usually made of cast iron. It provides support and rigidity to all other components and ensures the accurate alignment of the spindle and tailstock.

- Headstock: The headstock is situated at one end of the bed and contains the main spindle. The spindle rotates and holds the workpiece, typically by using chucks or collets. It may have multiple speed settings to control the rotational speed of the workpiece.

- Tailstock: The tailstock is located at the opposite end of the lathe bed and moves along the bed’s length. It serves as a support for the other end of the workpiece. The tailstock usually contains a center, which aligns with the center on the headstock, ensuring concentricity in the workpiece.

- Carriage: The carriage is a movable assembly that travels along the lathe bed, driven by hand or a feed mechanism. It holds the cutting tool and provides the means for longitudinal and transverse movement, allowing the cutting tool to shape the workpiece.

- Apron: The apron is attached to the carriage and contains various mechanisms, such as the gearbox and feed controls. It enables the operator to engage automatic feed for smooth and consistent cutting operations.

- Cross Slide: The cross slide is mounted on the carriage and permits lateral movement perpendicular to the lathe’s axis. It allows the cutting tool to move across the workpiece for facing or turning operations.

- Compound Rest: The compound rest is located atop the cross slide and permits two types of movements: angular movement for taper turning and longitudinal movement for facing angles.

- Chuck: Chucks are used to hold and secure the workpiece on the lathe’s spindle. They come in various designs, such as three-jaw chucks and four-jaw chucks, each suitable for different types of workpieces.

- Cutting Tool: The cutting tool is a tool bit that is secured in the tool post of the carriage. It shapes the workpiece by removing material as the workpiece rotates against it.

- Lead Screw: The lead screw is responsible for the thread cutting process. It connects the carriage to the spindle and allows automatic longitudinal movement during threading operations.

What are the characteristics of turning?

Turning is a machining process used to create cylindrical parts by removing material from a workpiece. It is typically used to create parts with a circular cross-section, such as shafts, pins, and spindles. Turning is a form of subtractive manufacturing, as material is removed from the workpiece to create the desired shape.

A lathe is a machine tool used to shape a workpiece by rotating it against a cutting tool. The cutting tool is typically a single-point cutting tool, such as a drill bit, but can also be a multi-point cutting tool, such as a milling cutter. The workpiece is typically held in place by a chuck, collet, or faceplate, and is rotated by a motor or hand crank.

The main components of a lathe include the bed, headstock, tailstock, carriage, and tool rest. The bed is the base of the lathe and provides support for the other components. The headstock houses the motor and spindle, which is used to rotate the workpiece.

What is purpose of turning?

Turning serves the primary purpose of altering the direction of a vehicle or object. It involves executing a maneuver that pivots the vehicle or object around its own axis, thereby redirecting its trajectory. This fundamental driving technique enables various functions, such as maneuvering around obstacles, changing lanes, entering or exiting highways, parking, and making U-turns. Apart from driving, turning finds application in diverse activities like sailing, skiing, and dancing.

In sailing, turning is instrumental in changing the boat’s course, while in skiing, it enables the skier to change direction. Similarly, dancers use turning to alter their orientation during their routines. Mastering the skill of turning is of utmost importance as it ensures safe and efficient navigation in any environment.

What is necessary condition for turning?

To enable a turn, the presence of a centripetal force is essential. This force acts upon an object, prompting it to change its direction of motion along a curved path. To achieve this change in direction, the centripetal force must outweigh the object’s inertia—the tendency to maintain its current motion state. Various sources can provide the centripetal force, including friction, gravity, or a string/rope attached to the object.

The magnitude of the centripetal force depends on 3 factors: the object’s mass, speed and radius of the turn. A larger mass, higher speed, and tighter turn radius demand a greater centripetal force to facilitate the object’s turning motion.

What is the basic principle of lathe operation quizlet?

Lathe operation revolves around the fundamental principle of shaping a workpiece by removing material. This process entails rotating the workpiece against a cutting tool, held in a tool holder, and guided along the workpiece in a linear manner. A single-point cutting tool like a drill bit is used, a multi-point cutting tool, such as a milling cutter, may also serve the purpose. These cutting tools are crafted from high-speed steel or carbide and are positioned at a specific angle in the tool holder relative to the workpiece.

To shape the workpiece, the cutting tool is advanced linearly along it while the workpiece is rotated at a particular speed. This movement of the cutting tool against the workpiece results in the gradual removal of material, eventually achieving the desired shape or form. The rotational speed of the workpiece and the feed rate of the cutting tool can be adjusted, providing precise control over the final product’s size and shape.

What are the advantages of turning?

Turning is a highly adaptable machining technique utilized to fabricate cylindrical components from diverse materials. Among the most prevalent and versatile machining methods, turning excels at producing a broad range of parts, from intricate small pieces to large and intricate shapes. It provides numerous advantages compared to other machining processes, which include:

- Exceptional Precision: Turning achieves remarkable precision by holding the cutting tool in a fixed position while rotating the workpiece. This meticulous control over the cutting process allows for the creation of parts with tight tolerances and exceptional accuracy.

- Enhanced Productivity: With its relatively swift and efficient nature, turning facilitates rapid production of parts, making it particularly advantageous for high-volume manufacturing.

- Unmatched Versatility: The versatility of turning is evident in its capacity to fabricate parts in various shapes and sizes. Whether it’s delicate intricacies or complex structures, turning can handle the task adeptly. Moreover, it accommodates a wide array of materials, including metals, plastics, and composites, further expanding its application range.

What are the three main movements of turning operations?

Turning operations are a type of machining process used to shape and finish a workpiece by removing material from the surface. The three main movements of turning operations are the cutting tool’s feed, the cutting tool’s rotation, and the workpiece’s rotation.

The feed movement is the linear motion of the cutting tool along the workpiece’s surface. This motion is usually controlled by a feed rate, which is the distance the cutting tool moves in a given amount of time. The feed rate is typically measured in inches per minute (IPM). The feed rate is important because it determines the amount of material that is removed from the workpiece.

The cutting tool’s rotation is the rotational motion of the cutting tool around its own axis. This motion is usually controlled by a spindle speed, which is the rotational speed of the cutting tool. The spindle speed is typically measured in revolutions per minute (RPM). The spindle speed is important because it determines the cutting speed and the surface finish of the workpiece.

What is rough turning?

Rough turning is a machining technique employed to swiftly eliminate substantial amounts of material from a workpiece, aiming to establish an initial rough shape or profile that can later undergo further refinement through finishing operations. Typically carried out on a lathe, rough turning can also be conducted using a milling machine or alternative machine tools.

The process entails the utilization of a cutting tool, such as a single-point cutting tool, which is held within a tool holder and advanced into the workpiece at a predetermined feed rate. The cutting tool is then guided along the workpiece’s surface in either a linear or circular motion, depending on the shape required. As it progresses, the cutting tool efficiently removes material from the workpiece, resulting in the creation of a rough form or profile.

Rough turning proves to be a rapid and efficient method for eliminating significant material from a workpiece. Its primary purpose lies in establishing a fundamental shape or profile that can later undergo further enhancement via a finishing operation.

What are the types of turning?

Turning is a machining process used to shape and finish components by removing material from the workpiece. It is one of the most common and versatile machining processes, and is used to create a variety of shapes and sizes. There are several types of turning processes, each with its own advantages and disadvantages.

The most common type of turning is manual turning, which is done by hand using a lathe. This type of turning is used for small parts and is relatively slow and labor-intensive. It is also limited in the complexity of shapes that can be created.

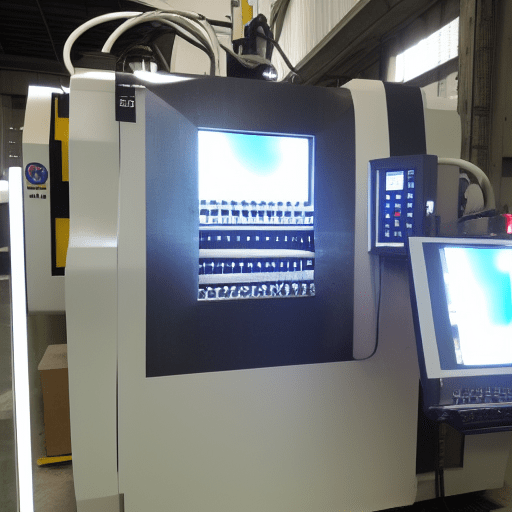

CNC (Computer Numerical Control) turning is a type of automated turning that is done using a computer-controlled lathe. This type of turning is much faster and more precise than manual turning, and can be used to create complex shapes and sizes.

Another type of turning is single-point turning, which is used to create cylindrical shapes. This type of turning is done using a single cutting tool that is moved along the workpiece in a linear motion.

What is the difference between turning and milling?

In the manufacturing industry, both turning and milling are prominent machining processes. Turning involves the creation of cylindrical parts by eliminating material from a rotating workpiece. This is achieved by using a cutting tool that works against the rotating workpiece to shape it as desired. Milling is also a machining process that employs a rotating cutting tool to remove material from the workpiece. Unlike turning, milling is specifically employed for fabricating flat and irregularly shaped parts, including the ability to craft intricate contours and complex shapes.

The primary distinction between turning and milling lies in the type of cutting tool they utilize. Turning relies on a single-point cutting tool, while milling utilizes a multi-point cutting tool. Turning is ideally suited for the production of cylindrical parts, whereas milling is more adept at creating flat and irregularly shaped components, offering greater versatility for crafting intricate designs and contours.