Turn milling is a machining process that combines traditional milling and turning operations. It is a process that allows for the simultaneous cutting of multiple features such as holes, slots, pockets, and contours in one setup. This is done by using a CNC machine with multiple cutting tools that are mounted in a turret. Mill turn machining is a more advanced type of CNC machining that is used to produce precision parts with complex geometries. It combines milling, turning and other operations, such as drilling, tapping, and reaming, in one setup. This process is done using a CNC machine with multiple axes and multiple cutting tools. It is used to produce high-precision parts with complex shapes, intricate features, and tight tolerances. The main difference between turn milling and mill turn machining is the number of cutting tools and operations used. Turn milling only uses one cutting tool, while mill turn machining uses multiple cutting tools and multiple operations in one setup. Additionally, turn milling is used to produce simpler parts with fewer features, while mill turn machining is used to produce more complex parts with multiple features.

Exploring the Differences between Turn Mill and Mill Turn Machining

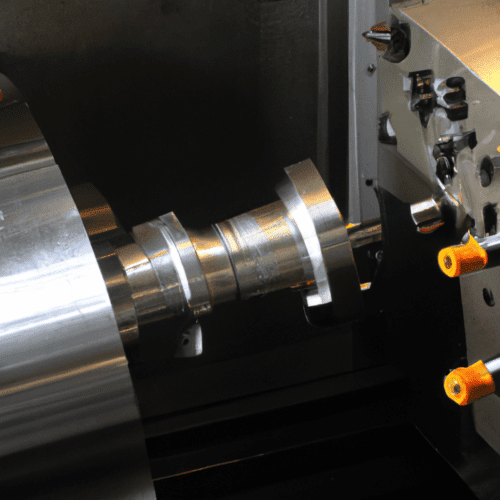

Mill turn machining is a type of machining that combines the processes of turning and milling. It is a highly precise and efficient process that is used to create complex parts with intricate features. Turn mill machining is a variation of mill turn machining that involves a combination of turning and milling, but with a focus on the turning operations. The difference between turn mill and mill turn machining is the emphasis on turning operations. In turn mill machining, the primary focus is on the turning operations. The parts are machined using a turning center, which typically consists of a spindle, a tool holder, and a chuck. The spindle is used to hold and rotate the workpiece while the tool holder is used to hold the cutting tool. The chuck is used to secure the workpiece in place during the machining process. The turning center rotates the workpiece and the cutting tool to create the desired shape and finish on the part. In mill turn machining, the emphasis is on the milling operations. The parts are machined using a milling center, which typically consists of a spindle, a tool holder, and a work table.

The spindle is used to hold and rotate the cutting tool while the tool holder is used to hold the workpiece. The work table is used to secure the workpiece in place during the machining process. The milling center moves the cutting tool and the workpiece to create the desired shape and finish on the part. The main difference between turn mill and mill turn machining is the focus on either turning or milling operations. In turn mill machining, the focus is on turning operations while in mill turn machining, the focus is on milling operations. Both processes are highly precise and can produce complex parts with intricate features. However, the emphasis on either turning or milling operations will determine the best process for a particular part.

What You Need to Know about Mill Turn and Turn Mill Machining

Mill turn and turn mill machining are two of the most popular types of machining used in the manufacturing industry. These processes are used to create complex parts with high precision and accuracy. They involve both turning and milling operations, thus often referred to as combined machining. Mill turn machining uses a combination of a turning center and a CNC milling machine to produce complex parts. It combines the rotating spindle of a lathe with the cutting tools of a mill to create parts with intricate shapes and details. The process is similar to that of traditional turning, but with the added capability of milling operations. This enables the machinist to achieve a high level of accuracy and precision when creating parts. Turn mill machining is a type of combined machining which combines the functions of both turning and milling. It uses a combination of cutting tools and machines to create parts with intricate shapes and details. The process is similar to that of mill turn machining, but with the added capability of using multiple axes of the machine to create parts with complex shapes and details.

Both mill turn and turn mill machining are highly accurate and precise processes, and they are often used in the production of automotive, aerospace, and medical components. They are also used to produce small parts such as screws and fasteners. Both processes require a high level of skill and experience in order to achieve the desired results. When selecting either process for your parts production, it is important to consider the capabilities of your machine and the type of material you are working with. Different materials require different cutting tools and techniques. Additionally, the complexity of the part you are creating will determine the type of machining process needed. Depending on the type of part you are creating, mill turn or turn mill machining may be the best solution for creating the desired parts.

Utilizing Turn Mill and Mill Turn Machining to Maximize Efficiency in Your Machining Projects

Turn mill and mill turn machining are two efficient processes used to produce complex parts. The combination of these two processes can significantly reduce machining times and improve the accuracy and quality of the finished parts. This article will explore the advantages of using turn mill and mill turn machining to maximize efficiency in machining projects. Turn mill machining is a process which combines both turning and milling operations. This process uses two different machines, a lathe and a milling machine, to produce parts with complex geometries. The lathe spins the workpiece, and the milling machine cuts and shapes it. This process is particularly effective for producing parts with complex shapes, such as those with multiple radii, tapers, and contours. It also allows for the creation of parts with both outer and inner diameters, as well as intricate details on the part’s surface. Mill turn machining is a process which combines the operations of a milling machine and a lathe. This process is similar to turn milling, however the workpiece is rotated much faster, allowing for higher precision and more intricate shapes. It is also capable of producing parts with internal and external threads, as well as other complex features.

In addition, mill turn machining minimizes the number of set-ups required, resulting in faster production times. The combination of turn mill and mill turn machining can offer a number of advantages over traditional machining methods. It reduces the amount of time and effort required to produce complex parts, as the process can be completed in a single set-up. The process also offers improved accuracy, as the two machines work together to create precise shapes and details. In addition, the process can reduce scrap rates and improve the quality of the finished parts. By utilizing turn mill and mill turn machining, manufacturers can maximize the efficiency of their machining projects. This process reduces production times and improves the accuracy and quality of the finished parts. It is a cost-effective solution for producing complex parts, and is an ideal choice for any machining project.

Understanding the Advantages and Disadvantages of Mill Turn vs. Turn Mill Machining

Mill turn machining and turn mill machining are two of the most commonly used machining processes in the manufacturing industry. Both processes have distinct advantages and disadvantages, and it is important to understand the differences between the two before selecting the right machining process for a particular application. Mill turn machining is a process in which a machine tool combines the functions of a milling and a turning machine to produce a single part. This process is often used for complex parts that require multiple operations to be performed in one setup. The main advantage of mill turn machining is that it allows for the production of large, complex parts in a single setup, which is more efficient than performing multiple operations separately. Additionally, mill turn machining produces a higher quality part because it eliminates the need for multiple setups, which can introduce errors. Turn mill machining is a process in which a single machine tool combines the functions of both a milling and a turning machine. This process is often used to produce complex parts that require multiple operations to be performed on a single part. The main advantage of turn mill machining is that it can produce parts quickly and with a high degree of accuracy.

Additionally, turn mill machining is very cost effective because it eliminates the need for multiple setups. However, both mill turn and turn mill machining processes have disadvantages. Mill turn machining requires specialized tools, which can be costly and difficult to find. Additionally, mill turn machining can be time consuming and complex due to the multiple operations that must be performed in a single setup. Turn mill machining can also be complex and time consuming due to the multiple operations that must be performed on a single part. Additionally, turn mill machining requires specialized tools, which can be costly and difficult to find. Overall, both mill turn and turn mill machining have advantages and disadvantages. It is important to understand the differences between the two processes before selecting the right one for a particular application. By considering the advantages and disadvantages of both processes, manufacturers can make an informed decision about which process is best suited to their production needs.

Comparing the Cost-Effectiveness of Turn Mill and Mill Turn Machining for Various Applications

Mill turn machining and turn mill machining are two distinct types of machining processes used for manufacturing components. In the machining industry, cost-effectiveness is an important factor when considering which type of process to use for certain applications. This article compares the cost-effectiveness of turn mill and mill turn machining for various applications. To begin with, turn mill machining is a process that combines the operations of turning and milling into a single process, whereas mill turn machining involves two separate operations. The cost-effectiveness of these processes depends on the type of application and the complexity of the component. For simple components with low complexity, such as shafts and pipes, turn mill machining is generally the most cost-effective option. This is because the process combines two operations into a single operation, and thus reduces the number of tool changes and setup times. Additionally, because the process is faster than mill turn machining, there is a decrease in labor costs.

For more complex components with higher levels of detail, such as those used in automotive and aerospace applications, mill turn machining is often the more cost-effective option. This is because the two distinct operations allow for greater accuracy and precision, and thus the components produced are of a higher quality. Additionally, because the two operations are separate, there is a greater level of flexibility in terms of tool selection and setup times, which can result in cost savings. Overall, the cost-effectiveness of turn mill and mill turn machining for various applications depends on the complexity of the component and the type of application. For simple components with low complexity, turn mill machining is typically the most cost-effective option, whereas for more complex components with higher levels of detail, mill turn machining is often the better choice.