The type of milling cutter you need will depend on the material you are cutting and the type of milling operation you are performing. Generally, there are four main types of milling cutters: end mills, slot drills, ball nose cutters, and face mills. End mills are used for making slots, pockets, and contours in a workpiece. Slot drills are used for making shallow holes and for plunging into a workpiece. Ball nose cutters are used for making curved surfaces and contours. Face mills are used for making flat surfaces and for cutting slots.

When selecting a milling cutter, you should consider the material you are cutting, the type of milling operation you are performing, the size of the cutter, and the number of cutting edges. For example, if you are cutting a soft material such as aluminum, you may want to use a high-speed steel (HSS) end mill. If you are cutting a harder material such as steel, you may want to use a carbide end mill.

How do I choose a milling cutter?

Choosing the right milling cutter for a particular job is an important decision that can have a major impact on the quality of the finished product. The first step in selecting the right milling cutter is to determine the type of material that will be machined. Different materials require different types of cutters, and the wrong type of cutter can cause damage to the material or the machine. Once the material has been identified, the next step is to determine the type of cut that is needed. Different types of cuts require different types of cutters, and the wrong type of cutter can cause poor quality results.

The next step is to determine the size of the cutter that is needed. The size of the cutter is determined by the size of the material that is being machined, as well as the type of cut that is needed. The size of the cutter should be slightly larger than the material that is being machined, as this will ensure that the cutter is able to make the desired cut.

Which type of cutter is used in milling machine?

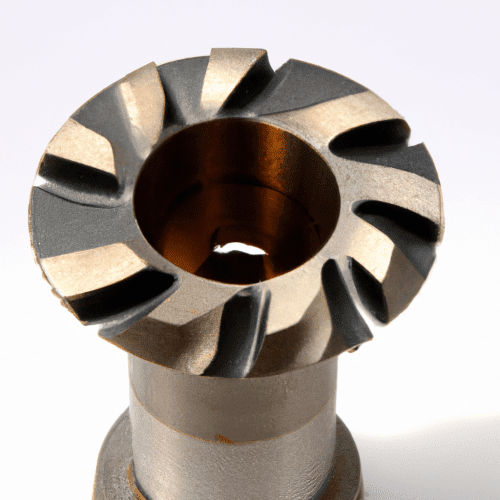

Milling machines use a variety of cutting tools to shape and form material. The most common types of cutting tools used in milling machines are end mills, face mills, shell mills, and reamers. End mills are used to cut slots, grooves, and other features into the workpiece. Face mills are used to cut flat surfaces into the workpiece. Shell mills are used to cut contours and other shapes into the workpiece. Reamers are used to finish and refine the surface of the workpiece. Each type of cutting tool has its own unique characteristics and is used for different applications.

What is the difference between a plain milling cutter and a side milling cutter?

A plain milling cutter is a type of rotary cutting tool used in metalworking. It has a cylindrical body with teeth on the periphery and is used to machine flat surfaces. It is typically used to machine slots, grooves, and other features in a workpiece. The cutting edges of the teeth are parallel to the axis of the cutter, and the cutting action is performed by the teeth as the cutter rotates.

A side milling cutter, on the other hand, is a type of rotary cutting tool used in metalworking. It has a cylindrical body with teeth on the periphery and is used to machine surfaces perpendicular to the axis of the cutter. It is typically used to machine slots, grooves, and other features in a workpiece. The cutting edges of the teeth are perpendicular to the axis of the cutter, and the cutting action is performed by the side of the teeth as the cutter rotates.

How do I select a cutting tool?

Selecting a cutting tool can be a difficult decision, as there are many factors to consider. The first step is to determine the type of material that needs to be cut. Different materials require different types of cutting tools, so it is important to know what type of material you are working with. Once you have determined the material, you can then decide on the type of cutting tool that is best suited for the job.

The next step is to consider the size and shape of the material that needs to be cut. Different cutting tools are designed to cut different shapes and sizes, so it is important to select a tool that is capable of cutting the material in the desired shape and size. Additionally, the cutting tool should be able to handle the thickness of the material.

The third step is to consider the speed and accuracy of the cutting tool. Different cutting tools are designed to cut at different speeds and with different levels of accuracy. It is important to select a tool that is capable of cutting the material at the desired speed and with the desired level of accuracy.

Why are there milling cutters with flutes?

Milling cutters with flutes are used in milling machines to cut and shape materials such as metal, wood, and plastic. The flutes are helical grooves that are cut into the cutter’s surface. These grooves are used to channel chips away from the cutting edge and provide a path for coolant to flow. The flutes also provide a cutting edge that is stronger and more durable than a flat surface.

The number of flutes on a milling cutter can vary depending on the material being cut and the desired finish. Generally, more flutes provide a smoother finish, while fewer flutes provide a rougher finish. The shape of the flutes can also vary, with straight flutes being the most common. Other shapes, such as spiral flutes, can be used to provide a better finish on certain materials.

The flutes on a milling cutter also help to reduce vibration and chatter during the cutting process. This is because the flutes act as a dampening mechanism, absorbing some of the vibration and noise generated by the cutting process.

How do you determine the diameter of a milling cutter?

The diameter of a milling cutter can be determined by measuring the distance from one cutting edge to the other cutting edge across the center of the cutter. This measurement should be taken with a caliper or micrometer, and should be taken at the widest point of the cutter. It is important to note that the diameter of the milling cutter is not the same as the shank diameter, which is the diameter of the shank that fits into the spindle of the milling machine. The shank diameter is usually smaller than the diameter of the cutter itself. Additionally, the diameter of the milling cutter can also be determined by measuring the diameter of the circle that the cutting edges form when the cutter is rotated. This measurement should be taken with a ruler or other measuring device.

When face milling What size cutter is recommended?

When face milling, the size of the cutter recommended depends on a variety of factors, such as the material being machined, the depth of cut, the desired surface finish, and the type of milling machine being used. Generally, a larger cutter is recommended for face milling operations, as it will provide a better finish and reduce the risk of chatter. The size of the cutter should also be determined by the size of the workpiece, as a larger cutter may not be able to fit in the available space. Additionally, the number of flutes on the cutter should be considered, as a higher number of flutes will provide a smoother finish. Finally, the speed and feed rate of the cutter should be adjusted to ensure that the cutter is not overloaded and that the desired finish is achieved.

How many types of milling cutters are there?

Milling cutters are cutting tools typically used in milling machines or machining centers to perform milling operations (and occasionally in other machine tools). They remove material by their movement within the machine (e.g., a ball nose mill) or directly from the cutter’s shape (e.g., a form tool such as a hobbing cutter).

There are several types of milling cutters, including:

1. End Mills: End mills are the most common type of milling cutters. They have cutting edges on the end and sides of the body and are used for making slots, grooves, and other features in a workpiece. They are available in a variety of shapes and sizes, and can be used for both roughing and finishing operations.

2. Slab Mills: Slab mills are large cutters that have a wide face and are used for making flat surfaces in a workpiece. They are available in a variety of sizes and shapes, and can be used for both roughing and finishing operations.

What is the difference between end milling and face milling?

End milling and face milling are both types of milling operations that involve the use of a milling machine, which is a machine tool used for the shaping of metal and other solid materials. End milling is a process that cuts away material from the end of a workpiece, while face milling is a process that cuts away material from the face of a workpiece.

The main difference between end milling and face milling is the direction in which the cutting tool moves. In end milling, the cutting tool moves perpendicular to the direction of the workpiece, while in face milling, the cutting tool moves parallel to the direction of the workpiece. End milling is typically used to create slots, grooves, and other features in the end of a workpiece, while face milling is used to create flat surfaces and other features on the face of a workpiece.

End milling is generally used for machining parts with complex shapes, while face milling is used for machining parts with flat surfaces.