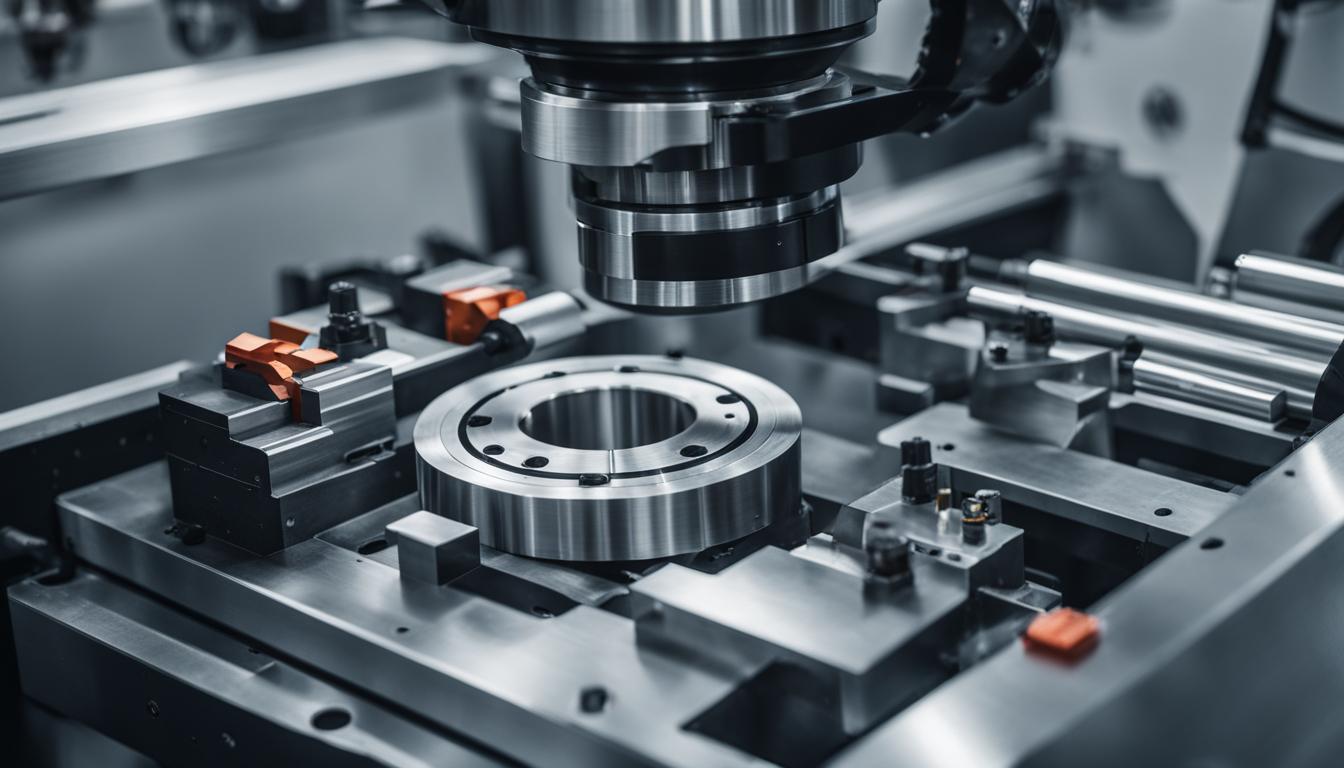

Precision machining is a crucial aspect of modern manufacturing industries, enabling the production of precise and complex parts. This article will explore the various processes and equipment commonly used in precision machining, shedding light on how they contribute to the creation of high-quality components.

Computer numerical control (CNC) technology plays a central role in precision machining, providing the means to achieve accuracy and efficiency. By utilizing CNC, manufacturers can perform intricate operations with exceptional precision, resulting in parts that meet tight tolerances and specifications.

When it comes to precision machining processes, several methods are widely employed. These include:

- CNC milling

- CNC lathe

- CNC drill

- CNC grinder

- CNC laser beam machining (LBM)

- CNC electrical discharge machines (EDM)

Each process utilizes specific tools and techniques to achieve the desired results. The choice of process depends on factors like the project requirements and the industry being served. Common industries that benefit from precision machining include automotive, aerospace, medical, and oil & gas.

- Precision machining is essential for producing precise and complex parts.

- Computer numerical control (CNC) technology enables accuracy and efficiency in precision machining.

- Common precision machining processes include CNC milling, CNC lathe, CNC drill, CNC grinder, CNC laser beam machining (LBM), and CNC electrical discharge machines (EDM).

- The choice of process depends on project requirements and industry needs.

- Precision machining finds applications in automotive, aerospace, medical, and oil & gas industries.

CNC Milling: A Common Precision Machining Process

CNC milling is a widely used process in precision machining that involves the use of rotary cutters to remove excess material from the workpiece. This process offers precise shaping and dimension control, making it suitable for various applications in industries like automotive, aerospace, and medical. Different types of mills, such as chamfer mills, end mills, helical mills, hand mills, plain mills, and universal mills, can be used in CNC milling. The choice of mill type depends on the specific requirements of the project.

The orientation of the mill, whether vertical or horizontal, is determined based on the approach to the workpiece. Vertical mills are commonly used for producing flat surfaces, while horizontal mills are suitable for cutting slots and grooves. CNC milling provides high accuracy and repeatability, allowing for the production of complex components with tight tolerances. The process is controlled by computer numerical control (CNC) systems, ensuring precise movements and efficient machining.

To illustrate the versatility of CNC milling, consider the following table, which showcases different milling tools and their specific applications:

| Milling Tool | Application |

|---|---|

| Chamfer Mill | Create beveled edges and chamfers |

| End Mill | Make slots, pockets, and contours |

| Helical Mill | Produce helical features like threads |

| Hand Mill | Perform manual milling operations |

| Plain Mill | Remove material from large surfaces |

| Universal Mill | Perform both vertical and horizontal milling |

As shown in the table, different milling tools offer specific capabilities to accommodate a wide range of machining requirements. CNC milling is a versatile and precise process that plays a crucial role in the field of precision machining.

https://www.youtube.com/watch?v=eVhXpSATmdk

CNC Lathe: Precision Machining on a Rotating Workpiece

CNC lathe is a crucial precision machining process that involves holding the workpiece in place on a machine and rotating it on various axes. This rotational movement allows for the creation of precise cylindrical shapes and complex components. The number of axes in a CNC lathe determines its machining abilities and the level of intricacy it can achieve.

Industries such as aerospace, automotive, and power generation heavily rely on CNC lathe for turning operations. By utilizing cutting tools, CNC lathe can remove material and shape the workpiece to meet the desired specifications. Its ability to work with rotating workpieces makes it ideal for producing accurate and symmetrical parts.

With CNC lathe, manufacturers can achieve exceptional precision and repeatability, ensuring consistent quality across production batches. The process offers a high degree of control over dimensional accuracy, allowing for tight tolerances and intricate designs. CNC lathe is a fundamental technique in precision machining, enabling the creation of various components with precise geometries.

CNC Drill: Creating Precise Holes with Precision Machining

In precision machining, the CNC drill plays a crucial role in creating precise cylindrical holes in workpieces. This process involves the use of a drill bit to remove excess material and create clean and accurate holes. The CNC drill is highly versatile and adjustable, allowing for the control of hole size and depth through machine tool calibration.

The CNC drill is commonly used in industries that require precise hole drilling, such as aerospace, automotive, and electronics. In aerospace applications, for example, the CNC drill is used to create holes for fasteners and rivets, ensuring the structural integrity of aircraft components. In the automotive industry, the CNC drill is employed for hole drilling in engine blocks, transmission casings, and other critical parts. In the electronics sector, the CNC drill is utilized for PCB (printed circuit board) production, where it creates holes for electrical connections and component mounting.

With its ability to consistently produce accurate and clean holes, the CNC drill plays a vital role in precision machining processes. It enables manufacturers to meet tight tolerances and ensures the functionality and reliability of the final products. By using the CNC drill, companies can achieve precise hole features that meet the specific requirements of their applications, allowing for seamless integration and efficient production processes.

| Industry | Application |

|---|---|

| Aerospace | Hole drilling for fasteners and rivets in aircraft components |

| Automotive | Hole drilling in engine blocks, transmission casings, etc. |

| Electronics | PCB production and hole drilling for electrical connections |

CNC Grinder: Enhancing Surface Quality in Precision Machining

When it comes to precision machining, achieving superior surface quality is crucial for ensuring the functionality and aesthetics of machined parts. This is where the CNC grinder plays a vital role. Using advanced technology, the CNC grinder is capable of enhancing the surface quality of machined components by providing a smooth and polished finish.

With precision and accuracy, the CNC grinder removes any remaining imperfections from the surface of the workpiece. By utilizing grinding wheels with different abrasive materials, it can effectively eliminate roughness, burrs, and other irregularities. This process not only enhances the aesthetics of the part but also improves its performance and functionality.

The CNC grinder is particularly important in industries such as automotive, aerospace, and medical, where the quality of the machined parts is of utmost importance. It allows manufacturers to achieve the desired surface finish required for various applications. Whether it is smoothing out rough edges or achieving a mirror-like surface, the CNC grinder ensures that the final product meets the highest standards of quality and precision.

| Advantages of CNC Grinder in Precision Machining | Applications |

|---|---|

| – Provides superior surface finish | – Automotive industry |

| – Removes surface imperfections | – Aerospace industry |

| – Enhances aesthetics | – Medical industry |

| – Improves performance and functionality | – Other industries requiring precise surface quality |

Overall, the CNC grinder plays a critical role in precision machining by ensuring the highest surface quality of machined components. It is an indispensable tool in industries where precision and aesthetics are essential, providing manufacturers with the ability to deliver products that meet the strictest standards of quality and precision.

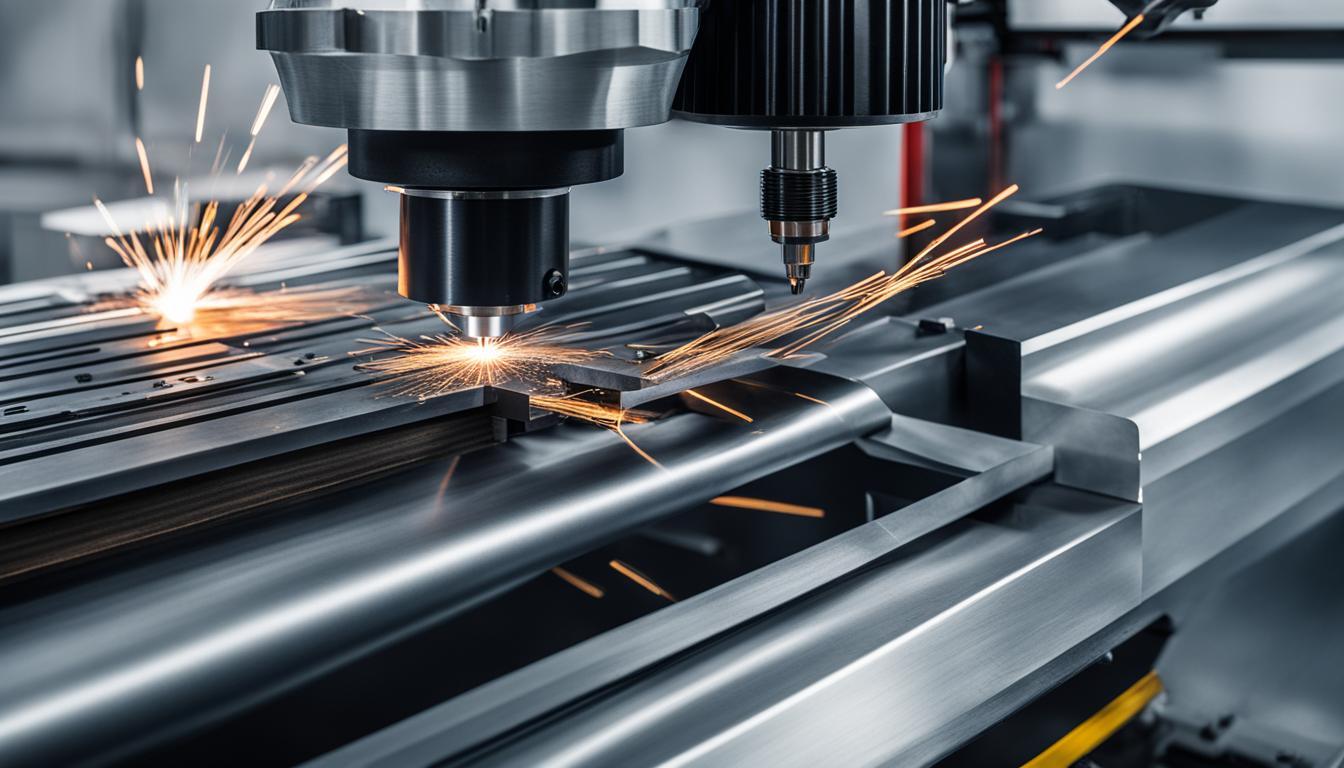

CNC Laser Beam Machining (LBM): Precision Cutting and Welding

CNC laser beam machining (LBM) is a highly precise and versatile process used in precision machining. It utilizes high-energy laser beams to heat and vaporize the material, resulting in precise cuts and welds. LBM offers exceptional accuracy and allows for intricate designs and complex geometries.

One of the key advantages of CNC LBM is its ability to cut a wide range of materials, including metals, plastics, ceramics, and composites. This makes it suitable for various applications in industries such as aerospace, automotive, electronics, and medical. The heat-affected zone in LBM is minimal, ensuring minimal distortion and preserving the material’s integrity.

In addition to cutting, CNC LBM is also used for drilling and welding. It provides unmatched precision and control, making it ideal for creating small, intricate holes and achieving high-quality welds. This process eliminates the need for additional post-processing steps, resulting in time and cost savings.

Applications of CNC Laser Beam Machining

- Precision cutting of sheet metal components for aerospace structures

- Creating fine contours and intricate shapes in automotive parts

- Drilling micro-holes in electronic components

- Precision welding of medical devices

Overall, CNC laser beam machining is a cutting-edge precision machining process that offers exceptional accuracy, versatility, and efficiency. Its ability to cut, drill, and weld with high precision makes it a vital technology in various industries.

CNC Electrical Discharge Machines (EDM): Precision Machining with Thermal Energy

CNC electrical discharge machines (EDM) are an integral part of precision machining processes. These machines utilize thermal energy to precisely remove unwanted material from the workpiece. By creating electrical sparks between the electrode and the workpiece, EDM allows for precise material removal. It is important to note that EDM can only be used with electrically conductive materials like aluminum, steel, stainless steel, brass, or copper, making it suitable for a wide range of applications.

The use of CNC EDM brings several advantages to precision machining. One of the key benefits is the ability to achieve intricate shapes and complex geometries with high accuracy. This makes EDM particularly valuable in industries such as automotive, aerospace, and medical, where precision is crucial. Additionally, CNC EDM allows for fine surface finishes, providing the desired level of quality for various applications.

In the table below, we highlight some of the key applications of CNC electrical discharge machines in precision machining:

| Industry | Application |

|---|---|

| Automotive | Manufacturing of engine components, gears, and transmission parts |

| Aerospace | Production of turbine blades, fuel system components, and structural parts |

| Medical | Fabrication of surgical instruments, dental implants, and orthopedic devices |

| Electronics | Creation of intricate circuitry, micro-components, and connectors |

CNC electrical discharge machines play a vital role in precision machining, offering the ability to achieve high precision, complex shapes, and fine surface finishes. With their application in various industries, CNC EDM continues to contribute to the advancement of manufacturing processes.

Advantages and Applications of Precision CNC Machining

Precision CNC machining offers a multitude of advantages that make it a preferred choice in various industries. One of the key advantages is the high level of accuracy that can be achieved. CNC machines are programmed to execute complex cuts and shapes with incredible precision, ensuring that each component is manufactured to the exact specifications required. This level of accuracy is crucial, especially in industries like aerospace and medical, where even the smallest deviation can have significant consequences.

Another advantage of precision CNC machining is the speed and efficiency of the process. CNC machines operate at high speeds, allowing for faster production rates compared to traditional manual machining. This increased efficiency not only saves time but also reduces overall production costs. Additionally, CNC machines can operate continuously, 24/7, further maximizing productivity and output.

The ability of precision CNC machining to produce complex geometries and tight tolerances opens up a wide range of applications across different industries. In the automotive sector, CNC machining is utilized for manufacturing engine components, transmission parts, and chassis components with exceptional accuracy. Aerospace companies rely on precision CNC machining for producing aircraft components, such as turbine blades and landing gear parts. Medical device manufacturers utilize CNC machining to create intricate surgical instruments and implants. Even the oil & gas industry benefits from precision CNC machining for manufacturing valves, connectors, and drilling equipment.

| Advantages of Precision CNC Machining | Applications |

|---|---|

| High accuracy | Aerospace |

| Fast and efficient | Automotive |

| Ability to produce complex geometries and tight tolerances | Medical |

| Oil & Gas |

In conclusion, precision CNC machining offers numerous advantages, including high accuracy, speed, and the ability to produce complex parts. These advantages, along with a wide range of applications in industries such as aerospace, automotive, medical, and oil & gas, make precision CNC machining an indispensable process in modern manufacturing.

Conclusion

Precision machining is a crucial process in the manufacturing industry, utilizing advanced equipment and CNC technology to transform raw materials into high-quality finished products. Through various processes like CNC milling, CNC lathe, CNC drill, CNC grinder, CNC laser beam machining (LBM), and CNC electrical discharge machines (EDM), precision machining offers exceptional accuracy and repeatability.

One of the key advantages of precision machining is its ability to produce complex parts with tight tolerances. This level of precision ensures that components fit together perfectly, enhancing the overall performance and functionality of the final product. Additionally, precision machining allows for the creation of smooth surface finishes, critical in industries that require high-quality aesthetics and optimal functionality.

The applications of precision machining are vast and diverse, ranging from the automotive and aerospace sectors to medical and oil & gas industries. Each industry benefits from the capabilities of precision machining, enabling the production of customized and reliable parts that meet rigorous standards. From producing intricate engine components to manufacturing intricate medical devices, precision machining plays a vital role in driving innovation and advancement across various sectors.

In conclusion, precision machining is an indispensable process in modern manufacturing. Its ability to achieve remarkable accuracy, consistency, and complexity makes it an essential tool for producing high-quality components across numerous industries. As technology continues to advance, precision machining will remain at the forefront of manufacturing processes, enabling the creation of innovative and reliable products.