Lathes are a type of machine tool used for shaping and machining metal, wood, and other materials. There are many different types of lathes available, each designed for a specific purpose.

The most common type of lathe is the engine lathe, which is used for general-purpose machining. This type of lathe is typically used for turning, facing, drilling, and threading operations. It is also used for producing cylindrical parts, such as shafts, spindles, and bushings.

Another type of lathe is the turret lathe, which is used for high-volume production of parts with complex shapes. This type of lathe is equipped with a turret that holds multiple cutting tools, allowing for quick and efficient production of parts.

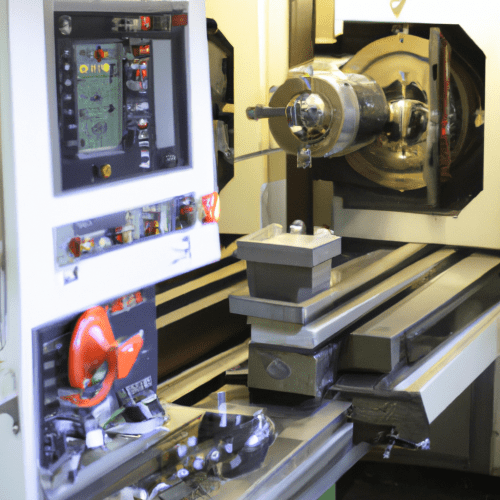

The third type of lathe is the CNC lathe, which is a computer-controlled machine tool. This type of lathe is used for producing parts with complex shapes and tight tolerances. It is also used for producing parts with intricate details, such as threads and grooves.

The fourth type of lathe is the special-purpose lathe, which is designed for specific operations. This type of lathe is used for operations such as grinding, knurling, and polishing. It is also used for producing parts with complex shapes and tight tolerances.

Finally, there is the multi-axis lathe, which is a combination of several lathes. This type of lathe is used for producing parts with complex shapes and tight tolerances. It is also used for producing parts with intricate details, such as threads and grooves.

What are the 3 main types of lathe?

The three main types of lathes are engine lathes, turret lathes, and special-purpose lathes.

Engine lathes are the most common type of lathe and are used for general-purpose turning operations. They are typically used to turn cylindrical shapes, tapers, and other simple shapes. They are also used to thread, bore, and ream. Engine lathes are usually powered by an electric motor and have a spindle that can be adjusted to different speeds.

Turret lathes are similar to engine lathes, but they have a turret that can be used to hold multiple cutting tools. This allows the operator to quickly switch between different tools without having to manually change them. Turret lathes are typically used for more complex operations such as drilling, tapping, and knurling.

Special-purpose lathes are designed for specific operations and are usually used for more complex operations.

What are the 9 different lathe operation?

Lathe operations are the various processes that can be performed on a lathe machine. Lathe operations can be divided into two main categories: turning and facing.

1. Turning: Turning is the process of removing material from a workpiece to create a desired shape. This is done by rotating the workpiece against a cutting tool. Common turning operations include facing, turning, boring, grooving, threading, and knurling.

2. Facing: Facing is the process of removing material from the end of a workpiece to create a flat surface. This is done by rotating the workpiece against a cutting tool. Common facing operations include facing, chamfering, and counterboring.

3. Drilling: Drilling is the process of creating a hole in a workpiece. This is done by rotating the workpiece against a cutting tool. Common drilling operations include drilling, reaming, and tapping.

Why lathe is called mother of all machines?

The lathe is a machine tool that has been used for centuries to shape and form materials such as wood, metal, and plastic. It is often referred to as the mother of all machines because it is one of the oldest and most versatile machine tools in existence. The lathe is used to create a variety of shapes and objects, from furniture to musical instruments. It is also used to create precision parts for machines and other tools.

The lathe is a machine that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, drilling, and turning. The workpiece is held in place by a chuck, which is a device that holds the workpiece in place while it is being worked on. The chuck is attached to the headstock, which is the part of the lathe that houses the motor and other components. The tailstock is the part of the lathe that holds the cutting tool.

What is CNC lathe machine?

A CNC lathe machine is a computer numerical control (CNC) machine tool that uses computer programming to automate the machining process. It is a type of lathe that uses computer-controlled motors to rotate the workpiece and cutting tools to produce precise parts with high accuracy and repeatability. CNC lathes are used in a variety of industries, including automotive, aerospace, medical, and electronics. They are used to produce parts such as shafts, gears, and other components with complex shapes. CNC lathes are capable of producing parts with tight tolerances and intricate details. They are also capable of producing parts with complex geometries, such as helical and spiral shapes. CNC lathes are highly efficient and can produce parts quickly and accurately. They are also capable of producing parts with a high degree of repeatability, which is important for mass production. CNC lathes are also capable of producing parts with a high degree of accuracy, which is important for precision parts.

What is capstan and turret lathe?

A capstan and turret lathe is a type of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable. It is a specialized form of a turret lathe, where the turret holds the cutting tools and is mounted on a slide that moves along the length of the bed. The turret is driven by a capstan, which is a rotating shaft with a series of cams that actuate the turret to move the cutting tools into position.

The capstan and turret lathe is a highly efficient machine for producing large quantities of identical parts. It is capable of performing a variety of operations, including turning, facing, drilling, reaming, and threading. The turret can be indexed to any position, allowing for quick and easy tool changes. The capstan is driven by a motor, which can be adjusted to provide the desired speed and feed rate.

The capstan and turret lathe is well suited for mass production of parts, as it is capable of producing parts with high accuracy and repeatability.