The type of cutter used for a particular operation depends on the material being cut, the desired finish, and the desired accuracy. Generally, the most common types of cutters are end mills, drill bits, reamers, and taps.

End mills are used for cutting slots, pockets, and contours in a workpiece. They are available in a variety of shapes and sizes, and can be used for both roughing and finishing operations. End mills are typically made from high-speed steel or carbide, and can be used on a variety of materials, including wood, plastic, and metal.

Drill bits are used for drilling holes in a workpiece. They are available in a variety of sizes and shapes, and can be used for both roughing and finishing operations. Drill bits are typically made from high-speed steel or carbide, and can be used on a variety of materials, including wood, plastic, and metal.

Reamers are used for enlarging and finishing existing holes in a workpiece. They are available in a variety of sizes and shapes, and can be used for both roughing and finishing operations. Reamers are typically made from high-speed steel or carbide, and can be used on a variety of materials, including wood, plastic, and metal.

Taps are used for cutting internal threads in a workpiece. They are available in a variety of sizes and shapes, and can be used for both roughing and finishing operations. Taps are typically made from high-speed steel or carbide, and can be used on a variety of materials, including wood, plastic, and metal.

What are the cutting operations?

Cutting operations are a type of machining process used to shape and form materials by removing excess material. This is done by using a cutting tool, such as a drill, milling cutter, lathe, router, or saw, to remove material from the workpiece. The cutting tool is usually moved in a linear motion, but can also be moved in a rotary motion. The cutting tool is usually made of a hard material, such as steel, and is designed to cut through the material being worked on.

Cutting operations can be divided into two main categories: roughing and finishing. Roughing operations involve removing large amounts of material from the workpiece in order to create a desired shape or size. This is usually done with a drill, milling cutter, or router. Finishing operations involve removing small amounts of material from the workpiece in order to create a smooth surface or to refine the shape of the workpiece. This is usually done with a lathe, router, or saw.

How do I choose a milling cutter?

Choosing the right milling cutter for a particular job is an important decision that can have a major impact on the quality of the finished product. The first step in selecting the right milling cutter is to determine the type of material that will be machined. Different materials require different types of cutters, and the wrong type of cutter can cause damage to the material or the machine. Once the material has been identified, the next step is to determine the type of cut required. This will determine the type of cutter that should be used, such as a face mill, end mill, or drill bit. The size of the cutter should also be considered, as it should be large enough to handle the job but not so large that it causes excessive wear on the machine. Additionally, the number of flutes should be considered, as this will affect the speed and quality of the cut. Finally, the type of coating on the cutter should be considered, as this will affect the durability and performance of the cutter.

How many types of cutters are there?

There are many different types of cutters available, depending on the material being cut and the desired result. Generally, cutters can be divided into two main categories: manual and power tools. Manual cutters include scissors, shears, knives, and saws. Power tools include drills, routers, jigsaws, and circular saws.

Within each of these categories, there are further subcategories of cutters. For example, manual cutters can be further divided into straight-edge cutters, such as scissors and shears, and curved-edge cutters, such as knives and saws. Power tools can be further divided into rotary cutters, such as drills and routers, and reciprocating cutters, such as jigsaws and circular saws.

In addition, there are specialty cutters designed for specific materials or tasks. For example, there are glass cutters for cutting glass, tile cutters for cutting tile, and miter saws for making angled cuts.

What is ball cutter used for?

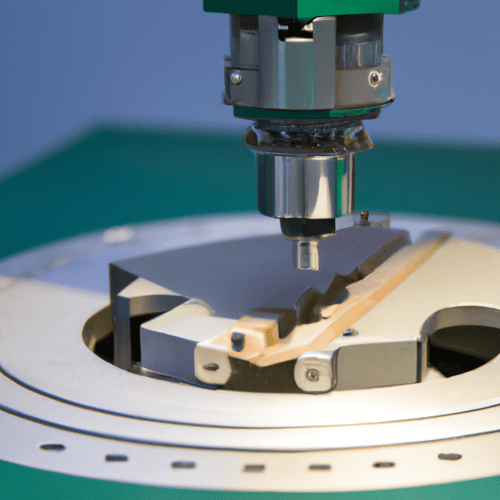

A ball cutter, also known as a spherical milling cutter, is a tool used for machining curved surfaces and contours. It is typically used in the manufacturing of dies and molds, as well as in the machining of curved surfaces on a variety of materials. The ball cutter is composed of a cylindrical body with a cutting edge at the end. The cutting edge is typically made of a hard material such as carbide or diamond. The cutting edge is designed to cut into the material being machined, creating a curved surface. The ball cutter is typically used in CNC (Computer Numerical Control) machining, where the cutting edge is programmed to move in a specific pattern to create the desired shape. Ball cutters are also used in manual machining, where the cutting edge is moved by hand to create the desired shape. Ball cutters are used in a variety of industries, including automotive, aerospace, medical, and industrial. They are used to create a variety of shapes, including curved surfaces, contours, and complex shapes.

What is side and face milling cutter?

Side and face milling cutters are a type of milling cutter used in machining operations. They are typically used to machine flat surfaces, but can also be used to machine angled surfaces and slots. Side and face milling cutters are typically used in conjunction with a milling machine, which is a machine tool used to shape and form materials such as metal and wood.

Side and face milling cutters are designed with a cutting edge on the periphery of the cutter body. This cutting edge is used to remove material from the workpiece. The cutting edge is typically made of high-speed steel or carbide, and is designed to cut through a variety of materials. The cutting edge can be straight or helical, depending on the application.

The cutting edge of the side and face milling cutter is typically designed to cut in a single direction. This is known as a “climb milling” operation.

What is form cutter in milling?

Form cutter in milling is a type of cutting tool used in milling machines to create shapes and holes in a workpiece. It is typically made from high-speed steel or carbide and is used to cut a variety of materials, including metal, wood, and plastic. Form cutters are available in a variety of shapes and sizes, and can be used to create a wide range of shapes and holes. The most common form cutters are end mills, which are used to create slots, grooves, and other shapes in a workpiece. Other types of form cutters include ball end mills, which are used to create rounded shapes, and chamfer mills, which are used to create beveled edges. Form cutters are typically used in conjunction with a milling machine, which is a machine tool used to shape and cut materials. The milling machine is used to move the form cutter across the workpiece, while the form cutter is used to cut the material.

What types of cutters are most often used on a vertical milling machine?

Vertical milling machines are most often used for precise and accurate machining of metal parts. The cutting tools used on a vertical milling machine are typically made of high speed steel or carbide and are available in a variety of shapes and sizes to accommodate different types of material. The most common types of cutters used on a vertical milling machine are end mills, face mills, shell mills, and fly cutters.

End mills are the most common type of cutter used on a vertical milling machine. They are used to create flat surfaces, slots, pockets, and grooves in a workpiece. End mills have a flat bottom and are used to create a flat surface on the top and bottom of the workpiece. They are available in a variety of sizes and shapes, including square, ball, and corner radius.

Face mills are used to create flat surfaces on the sides of a workpiece. They have a flat bottom and a cutting edge that is perpendicular to the workpiece.