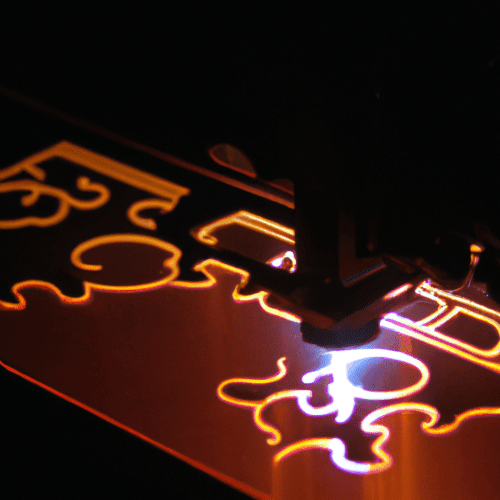

When it comes to laser cutting, the type of wood used is an important factor to consider. Different woods have different properties that can affect the quality of the cut, the speed of the cut, and the overall cost of the project.

Softwoods, such as pine, are generally the most cost-effective option for laser cutting. They are easy to cut and can be used for a variety of projects. However, they are not as durable as hardwoods and may not be suitable for projects that require a high level of precision.

Hardwoods, such as oak, are more expensive than softwoods, but they are also more durable and can provide a higher level of precision. They are also more resistant to heat, which can be beneficial when laser cutting.

Balsa wood is a lightweight wood that is often used for laser cutting. It is easy to cut and can be used for a variety of projects. However, it is not as durable as other types of wood and may not be suitable for projects that require a high level of precision.

What wood do I use for laser cutting?

The type of wood you use for laser cutting depends on the type of laser cutter you are using, as well as the type of project you are working on. Generally, the best woods for laser cutting are those that are light in color, have a fine grain, and are relatively soft. Examples of these woods include balsa, basswood, and plywood. Balsa is a lightweight wood that is easy to cut and engrave, making it a great choice for intricate projects. Basswood is a bit harder than balsa, but still relatively soft and easy to cut. Plywood is a great choice for larger projects, as it is strong and durable.

When selecting a wood for laser cutting, it is important to consider the type of laser cutter you are using. Some laser cutters are designed to work with specific types of wood, so it is important to check the specifications of your laser cutter before selecting a wood. Additionally, some woods may require additional preparation before they can be used with a laser cutter, such as sanding or sealing.

Is MDF good for laser cutting?

MDF (Medium Density Fiberboard) is a popular material for laser cutting due to its low cost, availability, and ease of use. It is a composite material made up of wood fibers and resin, and is available in a variety of thicknesses and sizes. MDF is a great material for laser cutting because it is easy to work with, and it produces a smooth, clean cut. It is also relatively inexpensive compared to other materials, making it a great choice for projects that require a large amount of material. Additionally, MDF is a great choice for projects that require intricate details, as the laser can easily cut through the material with precision. However, it is important to note that MDF is not suitable for outdoor use, as it is not waterproof and can be easily damaged by moisture. Additionally, MDF is not as strong as other materials, so it is not recommended for projects that require a lot of strength or durability. Overall, MDF is a great choice for laser cutting projects that require a low cost, easy to use material with a smooth, clean cut.

What thickness of wood can be laser cut?

The thickness of wood that can be laser cut depends on the type of laser cutting machine being used. Generally, most laser cutting machines can cut wood up to a thickness of 1/4 inch. However, some laser cutting machines are capable of cutting wood up to a thickness of 1/2 inch or even 3/4 inch. The type of laser cutting machine being used will determine the maximum thickness of wood that can be cut. Additionally, the type of wood being cut will also affect the maximum thickness that can be cut. Harder woods such as oak, maple, and walnut can usually be cut up to a thickness of 1/4 inch, while softer woods such as pine and cedar can usually be cut up to a thickness of 1/2 inch. It is important to note that the laser cutting process can cause the wood to char or burn, so it is important to use the correct settings for the type of wood being cut.

What kind of wood is best for laser engraving?

When it comes to laser engraving, the type of wood that is best depends on the desired outcome. Generally, hardwoods such as maple, walnut, and cherry are the best for laser engraving because they are dense and have a smooth surface. These woods are also less likely to burn or char when exposed to the laser. Softwoods such as pine and cedar are not ideal for laser engraving because they are more likely to burn or char when exposed to the laser. Additionally, softwoods are not as dense as hardwoods, so the laser engraving may not be as precise or detailed.

When selecting a wood for laser engraving, it is important to consider the grain of the wood. Woods with a tight, even grain are best for laser engraving because the laser will be able to follow the grain more easily. Woods with a wild or wavy grain may be more difficult to engrave because the laser may not be able to follow the grain as easily.

Can pine wood be laser cut?

Yes, pine wood can be laser cut. Laser cutting is a process that uses a high-powered laser to cut through materials such as wood, metal, and plastic. The laser beam is directed at the material, and the material is vaporized or melted away by the heat of the laser. Laser cutting is a precise and efficient way to cut materials, and it can be used to cut a variety of materials, including pine wood.

When laser cutting pine wood, it is important to consider the type of wood and the thickness of the material. Pine wood is a softwood, so it is relatively easy to cut with a laser. However, the thickness of the material will determine the power of the laser that is needed to cut it. Thicker pieces of pine wood will require a higher power laser than thinner pieces.

In addition to the type and thickness of the wood, the type of laser used will also affect the quality of the cut. CO2 lasers are the most common type of laser used for cutting wood, and they are capable of producing high-quality cuts.

Is pine wood good for laser cutting?

Pine wood is a popular choice for laser cutting due to its affordability and availability. It is a softwood, which makes it easier to cut than hardwoods, and it is also lightweight and easy to work with. Pine wood is also relatively easy to finish, making it a great choice for laser cutting projects.

The main advantage of using pine wood for laser cutting is that it is relatively inexpensive compared to other types of wood. It is also easy to find, as it is widely available in most lumber yards and home improvement stores. Additionally, pine wood is relatively easy to cut with a laser cutter, as it is a softwood and does not require as much power as hardwoods.

The main disadvantage of using pine wood for laser cutting is that it is not as durable as other types of wood. Pine wood is also not as strong as hardwoods, so it may not be suitable for projects that require a lot of strength.

Is plywood good for laser cutting?

Plywood is a popular material for laser cutting, as it is relatively inexpensive and easy to work with. It is also a good choice for laser cutting because it is strong and durable, and can be used to create intricate designs. Plywood is also a good choice for laser cutting because it is relatively thin and can be cut with a high degree of accuracy. Additionally, plywood is available in a variety of thicknesses, so it can be used for a variety of projects.

When laser cutting plywood, it is important to use the correct settings for the laser cutter. The settings should be adjusted to the thickness of the plywood, as well as the type of laser being used. Additionally, it is important to use the correct type of plywood for the project. For example, if the project requires a high degree of accuracy, then a higher grade of plywood should be used.

What wood is used for Glowforge?

The Glowforge laser cutter and engraver uses a variety of materials, including wood. The most common types of wood used with the Glowforge are plywood, baltic birch, and hardwoods such as maple, cherry, and walnut. Plywood is the most common type of wood used with the Glowforge because it is relatively inexpensive and easy to work with. Baltic birch is a higher-grade plywood that is more durable and has a smoother finish. Hardwoods such as maple, cherry, and walnut are more expensive but are also more durable and have a higher-quality finish. The Glowforge can also work with other types of wood, such as MDF, acrylic, and veneer. However, these materials are not as common and may require additional preparation before use.

What materials can a laser cutter cut?

A laser cutter is a powerful tool that can be used to cut a variety of materials. It uses a focused beam of light to cut through materials such as wood, acrylic, paper, cardboard, fabric, leather, and even some metals. The laser cutter is able to cut through these materials with precision and accuracy, making it a great tool for a variety of projects.

Wood is one of the most common materials that a laser cutter can cut. It can be used to create intricate designs and shapes in wood, as well as cut out large pieces. Laser cutters can also be used to engrave designs into wood, giving it a unique look.

Acrylic is another material that can be cut with a laser cutter. It is a strong and durable material that can be used to create a variety of shapes and designs. Acrylic is also a great material for engraving, as it can be used to create intricate designs and patterns.