Metal 3D printing is a rapidly advancing technology that is quickly becoming more accessible and more affordable. While it has many advantages over traditional manufacturing techniques, it is unlikely that it will replace CNC machines in the near future. Metal 3D printing is a relatively new technology that has the potential to revolutionize the way that metal parts are produced. This process, known as metal additive manufacturing, involves the use of a 3D printer that deposits layers of metal powder to build up a three-dimensional object. This method offers several distinct advantages over traditional CNC machining, including the ability to create complex shapes that would otherwise be impossible to produce, a reduced lead time for production, and improved efficiency in terms of material usage.

However, metal 3D printing is still in its early stages and is not yet able to compete with CNC machines in terms of precision and cost. CNC machines are still far more accurate and reliable than 3D printers, and they can produce parts more quickly and at a lower cost. Additionally, the materials used in 3D printing are still limited in comparison to the range of metals that can be machined. In the near future, it is unlikely that metal 3D printing will completely replace CNC machines in the production of metal parts. While this technology has the potential to revolutionize the manufacturing process, it is still in its infancy and is not yet able to compete with traditional methods in terms of accuracy and cost. In the years to come, however, metal 3D printing is likely to become increasingly more viable and may eventually become a viable alternative to CNC machining.

How 3D Printing Technologies are Changing the Manufacturing Industry

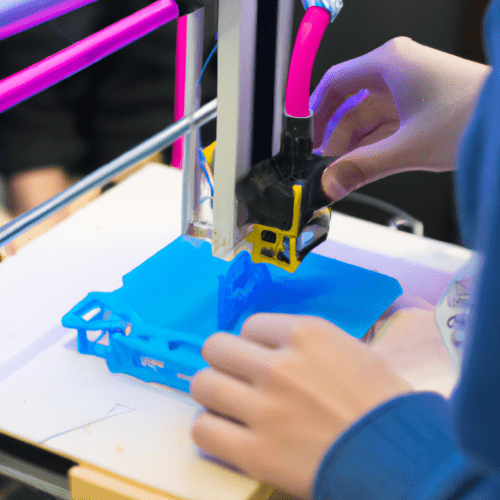

3D printing technologies are revolutionizing the manufacturing industry. This innovative technology allows manufacturers to produce products quickly, with improved accuracy, and at a reduced cost. 3D printing is a process used to create three-dimensional objects from a digital model. The process begins by creating a digital design of the object, which is then fed into the 3D printer. The printer then layers small amounts of material, such as plastic, metal, or ceramic, to form the object being printed. This process is significantly faster than traditional manufacturing methods, and can be used to produce parts that are difficult or impossible to create using other techniques. One major advantage of 3D printing is the ability to create complex designs with greater accuracy. Traditional manufacturing techniques often require multiple processes to produce a single component, each of which can introduce errors that can affect the accuracy of the final product.

3D printing, however, eliminates the need for multiple processes and can produce parts with greater precision. In addition, 3D printing has the potential to reduce production costs. By eliminating the need for multiple processes, manufacturers can save time and money. Additionally, 3D printing can be used to produce parts on-demand, which eliminates the need for large inventories and reduces the cost associated with storing and shipping parts. Finally, 3D printing allows manufacturers to produce custom parts more quickly and easily. This can be especially beneficial for companies that produce specialized products or require rapid prototyping. 3D printing can also reduce the time and cost associated with retooling for new products, as the printer can easily switch between production runs. Overall, 3D printing technologies are revolutionizing the manufacturing industry by providing manufacturers with a faster, more accurate, and more cost-effective way to produce products. The flexibility and precision of 3D printing make it ideal for producing complex parts, custom components, and rapid prototypes. As 3D printing technologies continue to develop, manufacturers will be able to take advantage of these benefits to improve their processes and create higher quality products.

Exploring the Impact of Metal 3D Printing on the CNC Machine Industry

Metal 3D printing technology has been gaining increasing attention and popularity in the manufacturing industry in recent years as a way to create complex shapes with high precision. This has had a significant impact on the CNC machine industry, as 3D printing is often seen as a more cost-effective and efficient solution for certain types of projects. Manufacturers have begun to turn to 3D printing for the production of increasingly complex parts that require intricate geometries and designs. The process involves using a computer-controlled machine to deposit molten metal onto a build platform, layer by layer, until the desired shape is created. This allows for the creation of parts that would otherwise be extremely difficult or impossible to produce with traditional CNC machining methods. The use of 3D printing for metal parts has created a need for new materials and processes that are compatible with 3D printing. This has opened up a new market for companies who can provide materials and services for 3D printing applications.

At the same time, CNC machining is still required for certain parts and applications. CNC machines are still used to create precision parts with tight tolerances, and for production volumes that are too high to be efficiently produced with 3D printing. The impact of 3D printing on the CNC machine industry is two-fold. On the one hand, it has opened up new opportunities for manufacturers who are able to provide the materials and services needed for 3D printing. On the other hand, it has also created competition for CNC machines in certain applications. As more manufacturers turn to 3D printing for complex parts, the demand for CNC machines may decrease. Overall, the impact of 3D printing on the CNC machine industry is still unfolding. While it may take some time for the full implications of this technology to be realized, it is clear that 3D printing is having an impact on the industry, and will continue to do so in the future.

Evaluating the Advantages and Disadvantages of Metal 3D Printing Compared to CNC Machines

Metal 3D printing and CNC machines are both powerful tools used in the manufacturing process of producing components and products. Both technologies offer their own set of advantages and disadvantages when it comes to producing complex parts or components with precision and accuracy. Advantages of Metal 3D Printing Metal 3D printing offers a great number of advantages when compared to CNC machines. One of the main advantages is that 3D printing is much more cost-effective. 3D printing eliminates the need for many costly machining operations and also reduces the time required for production. Additionally, 3D printing is not limited by the complexity of a part. It can easily produce complex components that would otherwise be impossible to make with a CNC machine. Additionally, 3D printing does not require expensive tooling and is also not limited by the material that can be used.

The main disadvantage of 3D printing is that it is much slower than a CNC machine. Additionally, 3D printing is not suitable for high-volume production, as the cost of materials and the time required can add up quickly. Furthermore, 3D printing has a limited accuracy and is not suitable for producing components with tight tolerances. Lastly, 3D printing is not suitable for producing components with intricate details, as the layers of material can be visible to the naked eye. Advantages of CNC Machines CNC machines offer a great number of advantages when compared to 3D printing. One of the main advantages is that CNC machines are much faster than 3D printing. CNC machines are also much more accurate and can easily produce components with tight tolerances. Additionally, CNC machines are suitable for high-volume production and can quickly produce large quantities of components. Lastly, CNC machines are much more suitable for producing components with intricate details, as the components produced are smooth and of high quality. Disadvantages of CNC Machines The main disadvantage of CNC machines is that they are much more expensive than 3D printing.

Additionally, CNC machines require expensive tooling and are limited by the complexity of a part. Furthermore, CNC machines are limited to the materials that can be used and are not suitable for producing components with complex shapes or designs.

Exploring the Potential of Metal 3D Printing to Revolutionize CNC Machine Production

The potential of metal 3D printing to revolutionize the CNC machine production process is immense. This technology has the potential to significantly reduce costs associated with the production of CNC machines, while at the same time increasing the efficiency of production. Metal 3D printing is a process in which a 3D printer uses a computer-aided design (CAD) file to produce a three-dimensional part from a variety of metals. The CAD file is used to control the 3D printer, which uses a laser or electron beam to precisely melt and fuse the metal powder together layer by layer until the part is complete. This process has several advantages over traditional CNC machine production methods. For one, metal 3D printing can help reduce the cost of producing a CNC machine. Since metal 3D printing allows for the production of complex parts with minimal waste, the cost of raw materials and labor are greatly reduced. Additionally, since the 3D printer can print components with very thin walls and intricate details, the overall size of thexCNC machine can be reduced, resulting in a more efficient production process.

Moreover, metal 3D printing allows for more flexibility when it comes to customization of CNC machines. Since individual parts can be printed on demand, customization of parts is made possible, allowing for more precise production of CNC machines. And with the use of 3D scanning technologies, parts can be printed to fit specific requirements, thus reducing time and cost in the production process. Finally, metal 3D printing can also help reduce the lead time associated with the production of CNC machines. Since the 3D printer can produce parts quickly and accurately, the lead time associated with the production of components can be greatly reduced, allowing for a faster production process. Overall, metal 3D printing can revolutionize the production of CNC machines by reducing costs associated with raw materials and labor, increasing the efficiency of production, and reducing lead times. This technology can provide a cost-effective and efficient solution to CNC machine production.

Examining the Feasibility of Fully Replacing CNC Machines with Metal 3D Printing in the Near Future

Metal 3D printing has been receiving increased attention in recent years as a potential replacement for traditional CNC machines. At its core, 3D printing is a process of building parts layer by layer, as opposed to CNC machining, which uses cutting tools to remove material from a solid block to create the desired shape. Despite the differences in the manufacturing process, both methods have the potential to produce parts with comparable accuracy and quality. The advantages of 3D printing over CNC machining become particularly apparent when producing complex parts with intricate geometries. With 3D printing, the entire part is built at once, which eliminates the need for separate manufacturing steps and reduces the time and cost of production. 3D printing also requires less labor, eliminating the need for manual machining, making it easier to achieve high levels of precision and consistency. Despite all of these advantages, there are some drawbacks to 3D printing that must be taken into consideration. For one, the cost of 3D printing is still substantially higher than that of CNC machining.

Additionally, 3D printing technology is still relatively new and less developed than traditional machining, making it harder to achieve high levels of accuracy and repeatability. The materials used for 3D printing are also often more expensive than those used for CNC machining. All in all, while 3D printing is a promising technology with many potential benefits, it is not yet ready to fully replace CNC machines. The technology is still in its early stages and requires further development before it can be used to replace traditional machining methods. That being said, with recent advances in 3D printing technology, it is becoming increasingly feasible to use 3D printing for certain applications and materials, and in the near future, 3D printing may become an extremely viable replacement for CNC machining.