Finding CNC machinists can be a difficult task due to a variety of factors. Firstly, the job requires a certain level of technical expertise which is not always easy to come by. Additionally, many CNC machinists are experienced professionals who are in high demand, making them difficult to find. Moreover, the job can be labor intensive, requiring an individual to work long hours and with precision, which can be a turn off for some potential applicants. Furthermore, CNC machinists often need to be well versed in the use of computer-aided design software, placing even more demands on potential applicants. Lastly, CNC machinists must be able to adjust quickly to changing technology and processes, making it a difficult job to fill.

What Skills Make CNC Machinists So Valuable and Difficult to Find?

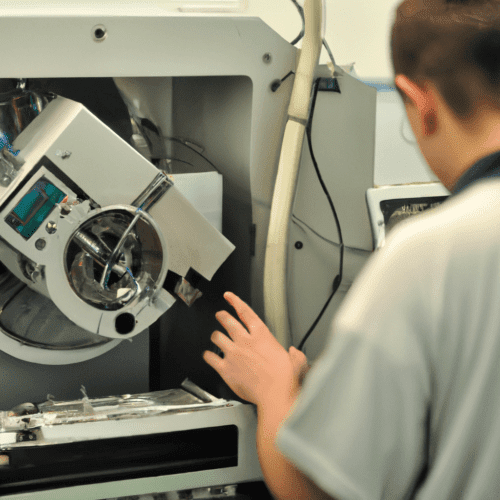

CNC machinists are highly sought-after professionals in the industrial manufacturing sector due to their valuable skills and expertise. CNC machinists are responsible for operating CNC (Computer Numerical Control) machines which are used to produce precision parts and components. To become a competent CNC machinist, individuals must have a combination of technical knowledge, manual dexterity, and problem-solving skills. The technical knowledge required involves a thorough understanding of engineering drawings, geometric dimensioning and tolerancing (GD&T), and the ability to read and interpret blueprints. Manual dexterity is essential for CNC machinists to be able to accurately set up and operate CNC machines.

Problem-solving skills are necessary to troubleshoot and fix technical issues with the machines. In addition to these technical skills, CNC machinists must also demonstrate excellent attention to detail, as even the smallest mistake can result in costly mistakes. They must also be able to work independently and have good organizational skills to ensure that parts and components are produced accurately and on time. Overall, CNC machinists require a wide range of skills and expertise which can be difficult to find in a single individual. As such, these professionals are highly valued in the industrial manufacturing sector and their skills are in high demand.

Is the CNC Machinist Field Becoming Oversaturated?

The CNC machinist field has experienced tremendous growth in recent years, with the demand for skilled professionals continuing to increase. However, the same cannot be said for all machinist positions. While some areas of the machinist field are seeing a steady influx of new workers, others are feeling the pressure of a possible oversupply of workers. As advancements in technology have made CNC machining more efficient and cost-effective, more businesses are turning to these machines to reduce labor costs and increase production. This has resulted in a steady increase in demand for CNC machinists, especially in the automotive, aerospace, and medical device industries. However, not all areas of the field are experiencing this same level of growth. For example, the demand for manual machinists has decreased significantly in recent years due to the increased efficiency of CNC machines. The increased demand for CNC machinists has resulted in an influx of new workers entering the field.

This has led to a possible oversupply of machinists in some areas, with employers having difficulty finding qualified applicants. This could be due to a lack of education and training opportunities, or a lack of awareness of the career opportunities in the field. The oversupply of machinists has also led to increased competition for available positions. This can lead to a decrease in wages, as employers may be able to pay lower wages to machinists in order to remain competitive. This can also lead to a decrease in job satisfaction, as machinists may find themselves having to work longer hours and take on more challenging projects in order to remain competitive and secure employment. Overall, it is difficult to determine whether the CNC machinist field is becoming oversaturated. While some areas may be feeling the pressure of an oversupply of workers, other areas are experiencing a steady increase in demand. It is important for those looking to enter the field to research the job market in their area in order to determine the best career path for them.

How to Attract CNC Machinists in a Competitive Job Market

Attracting CNC machinists in a competitive job market can be difficult. However, there are several steps that employers can take to increase their chances of success. First, employers should make sure that their job descriptions are clear and concise. Job descriptions should include the skills and experience needed for the role, as well as any potential benefits that the job may offer. This will help to attract qualified applicants and give them a better understanding of the job. Second, employers should be prepared to offer competitive salaries and other incentives. CNC machinists are in high demand, so employers should be aware of the competition and be willing to pay competitive rates. Additionally, employers should consider offering additional benefits such as paid vacation, health insurance, and other perks to make the job more attractive. Third, employers should make sure that their workplace is a pleasant and safe environment.

CNC machinists are expected to work in hazardous conditions, so employers should make sure that safety protocols are in place and the workspace is well-maintained. This will help to ensure that CNC machinists feel comfortable and secure in their job. Finally, employers should focus on developing relationships with potential candidates. By networking with local schools and community organizations, employers can become familiar with potential CNC machinists and may be able to offer them job opportunities. Additionally, employers should consider hosting events such as career fairs or workshops to engage with potential candidates. By taking these steps, employers can increase their chances of attracting CNC machinists in a competitive job market.

What Are the Benefits of Working as a CNC Machinist?

Working as a CNC machinist provides many benefits. Firstly, the job can be both physically and mentally rewarding. Working with precision machines can be a challenging, yet satisfying task. It requires a great deal of attention to detail and an ability to think critically and creatively to solve problems. Secondly, CNC machinists have the opportunity to work in high-tech, interesting environments. CNC machinists work with a variety of sophisticated machines and cutting-edge technology. This can be a great way to stay up-to-date on the latest developments in the industry. Thirdly, CNC machinists often have the opportunity to participate in interesting projects. As a machinist, you may be asked to create intricate parts or components for aerospace, automotive, medical, and other industries. This can be an exciting and rewarding experience, as you get to be part of something bigger than yourself. Finally, CNC machinists are in high demand.

As the world continues to move towards automation, more and more industries require skilled machinists to operate and maintain their machines. This means that CNC machinists are likely to have a steady job with plenty of room for advancement. In conclusion, becoming a CNC machinist can be an extremely rewarding job. It offers a variety of advantages, such as the opportunity to work with complex machines and cutting-edge technology, the chance to work on interesting projects, and a steady job with plenty of growth potential.

The Pros and Cons of CNC Machining and Its Skill Set Requirements

CNC (Computer Numerical Control) machining is a form of manufacturing used to create parts and components from a variety of materials, including metals, plastics, and ceramics. It is an automated process that utilizes a computer, which translates a design into commands understood by the CNC machining tool. CNC machining is a versatile and efficient form of production that has become increasingly popular in many industries. The primary advantages of CNC machining are that it is highly accurate, repeatable, and efficient. CNC machines are capable of producing high-precision parts and components with a tolerance as low as a few microns. Additionally, CNC machining can be used to produce parts more quickly than manual machining. The accuracy and repeatability of CNC machining make it ideal for parts that must fit together perfectly or require precise dimensions. Despite its many advantages, CNC machining does have some drawbacks.

CNC machines are expensive and require a significant amount of setup time, making it difficult to quickly change from one job to another. Additionally, CNC machining requires a special set of skills and expertise to operate, and it is not always easy to find qualified personnel. In order to operate a CNC machining machine, a person must have a good understanding of mathematics, computer programming, and manufacturing concepts. In addition, they must be able to read blueprints and drawings, and be able to interpret the commands from the computer to the machine. CNC machining is a highly technical process, and requires a high level of skill and experience. Overall, CNC machining is a cost-effective and efficient form of manufacturing that can be used to produce high-precision parts and components. However, it is important to consider the skill and expertise required to operate the machines, as well as the cost of the equipment and setup time. With the right personnel and an understanding of the process, CNC machining can be a powerful tool for any production environment.