CNC software can significantly enhance manufacturing efficiency through five key ways: optimization of toolpaths, reduction of material waste, improved machine utilization, enhanced quality control, and streamlined workflow integration. By optimizing toolpaths, CNC software calculates the most efficient routes for cutting tools, reducing machining time and tool wear. Material waste is minimized through precise nesting and cutting strategies, leading to cost savings and improved sustainability.

Machine utilization is boosted by intelligent scheduling and real-time monitoring, ensuring maximum productivity from each piece of equipment. Quality control is enhanced through simulation and verification features, catching potential errors before they occur on the shop floor. Lastly, CNC software integrates seamlessly with other manufacturing systems, creating a streamlined workflow from design to production, reducing bottlenecks and improving overall efficiency.

These combined benefits of CNC software can lead to substantial improvements in manufacturing speed, accuracy, and cost-effectiveness, ultimately driving business growth and competitiveness in the industry.

- CNC software optimizes operations and enhances workflow in manufacturing.

- Automation with CNC machines reduces labor costs and saves time.

- CNC machines are versatile and customizable, meeting unique client needs.

- Using CNC software improves accuracy and boosts production output.

- CNC software enables businesses to achieve efficiency and innovation in the competitive industrial landscape.

The Power of CNC Cutting Machines

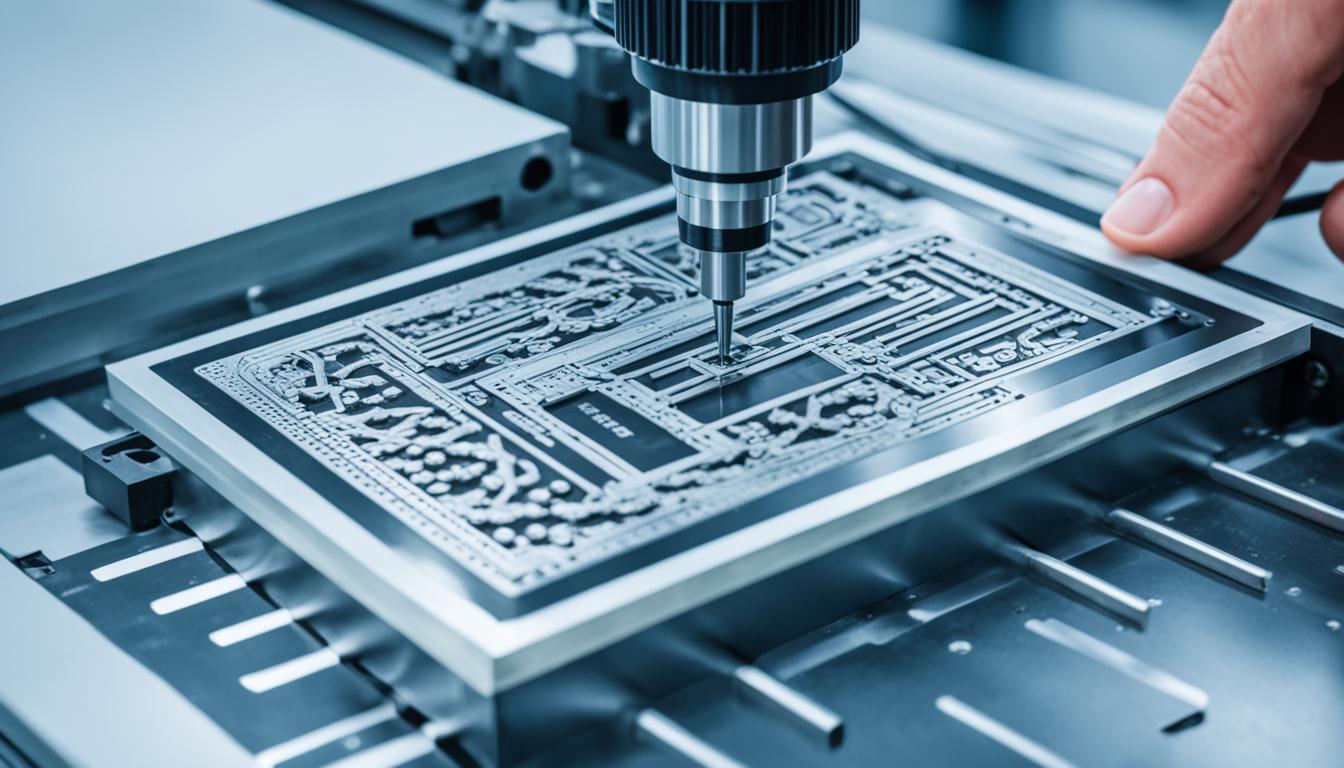

CNC cutting machines, such as plasma and router systems, offer unmatched precision in industrial processes. These machines are driven by computer programs that control cutting tool movements, ensuring accurate and high-quality cuts while minimizing material waste.

By automating industrial processes with CNC machines, businesses can achieve significant cost savings through reduced labor costs and optimized resource allocation. Moreover, CNC cutting machines operate at high speeds, reducing production time and increasing output. These time-saving efficiencies result in substantial cost savings and improved profit margins for businesses.

With CNC cutting machines, companies can achieve precise and accurate cuts, eliminating the margin for error commonly associated with manual cutting methods. This level of precision not only enhances the quality of the final product but also reduces material waste, resulting in cost savings. By automating the process, businesses can consistently produce accurate cuts, ensuring customer satisfaction and maintaining a competitive edge in the market.

Moreover, CNC cutting machines reduce reliance on manual labor, leading to significant cost savings. These machines can operate continuously and efficiently, minimizing downtime and streamlining production processes. By automating tasks that were once performed manually, businesses can optimize resource allocation and improve overall workflow, further enhancing efficiency and productivity.

By implementing CNC cutting machines in their operations, businesses can experience a drastic reduction in production time. These machines are capable of performing tasks at high speeds, significantly reducing the time required to complete a project. The increased production speed translates into a higher output rate and faster turnaround times, enabling businesses to meet deadlines and customer demands efficiently.

To give you a clearer picture of the cost-saving potential of CNC cutting machines, take a look at the table below:

| Cost Savings Achieved with CNC Cutting Machines | Manual Cutting Method | CNC Cutting Machine |

|---|---|---|

| Labor Costs | $6,000 | $2,500 |

| Material Waste | 35% | 5% |

| Production Time | 8 weeks | 4 weeks |

As demonstrated in the table, CNC cutting machines can lead to substantial cost savings in labor costs, material waste, and production time. These savings directly contribute to improved profit margins and provide businesses with a competitive advantage in the market.

The Promise of Automation in CNC Cutting Machines

One of the key features of CNC cutting machines is their automation capability. By leveraging advanced machining technology, businesses can minimize human intervention, reducing the risk of errors and inconsistencies that can plague manual cutting methods. The precision and accuracy provided by CNC cutting machines ensure that each cut meets the required specifications, boosting overall product quality.

Automation not only improves the consistency and accuracy of cuts but also enhances the overall efficiency of industrial processes. By automating labor-intensive tasks, businesses can allocate resources more effectively, optimize production schedules, and reduce the likelihood of bottlenecks or delays. This increased efficiency not only saves time but also lowers production costs, resulting in higher cost savings.

Investing in CNC cutting machines is a strategic decision that can transform the way businesses operate. By embracing automation, businesses can unlock the full potential of precision, speed, and efficiency. The resulting cost savings, increased productivity, and improved output quality position companies for sustainable growth and success in today’s competitive market.

Streamlining Operations and Reducing Costs

Automating industrial processes with CNC cutting machines offers numerous benefits, including drastic reductions in labor costs and efficient resource allocation. By eliminating manual tasks, businesses can allocate resources more effectively and reduce the need for manual labor.

CNC machines operate at incredible speeds, significantly reducing production time and increasing output. These time-saving efficiencies ultimately lead to substantial cost savings and improved profit margins for businesses.

Implementing CNC technology helps companies achieve cost savings through automating repetitive tasks and reducing the reliance on manual labor. By automating industrial processes, businesses can optimize their resource allocation and eliminate the risk of human error, ensuring consistent quality control and reducing rework. This streamlining of operations results in enhanced productivity, reduced production time, and increased output, allowing businesses to meet market demand efficiently.

Furthermore, reducing manual tasks through CNC automation leads to significantly reduced labor costs. CNC machines can perform complex tasks with precision and speed, eliminating the need for extensive manual labor. This reduction in labor costs translates into significant cost savings for businesses, enabling them to allocate resources to other critical areas of operation.

The enhanced efficiency achieved through automating industrial processes with CNC cutting machines not only reduces costs but also increases profit margins. With reduced labor costs and optimized resource allocation, businesses can maximize their production potential and achieve higher output with the same or fewer resources. This increased output, coupled with the cost savings from reduced labor, directly impacts the bottom line, resulting in improved profit margins and overall business success.

By streamlining operations and reducing costs, businesses can not only improve their financial performance but also gain a competitive edge in the market. The ability to produce goods efficiently and cost-effectively allows businesses to offer competitive prices and respond quickly to market demands. This strategic advantage positions companies to capture a larger share of the market and drive sustainable growth.

Implementing CNC cutting machines to automate industrial processes is a strategic move that delivers tangible benefits, ranging from cost savings to increased production efficiency and profitability. By embracing CNC technology, businesses can streamline their operations, reduce costs, and position themselves for long-term success in today’s highly competitive industrial landscape.

Versatility and Customization

CNC cutting machines are incredibly versatile, offering a solution for a wide range of cutting requirements. Whether businesses need to cut through thick metals or create intricate patterns, CNC machines have the flexibility to handle diverse tasks with precision and efficiency. By leveraging the customization capabilities of CNC cutting machines, businesses can meet the unique needs of their clients and deliver personalized products that stand out in the market.

In today’s competitive landscape, customization is key to staying ahead of the market competition. CNC cutting machines enable businesses to adapt and cater to the specific demands of their clients, providing tailored solutions that align with their preferences. Whether it’s creating personalized signage, intricate designs, or unique prototypes, CNC machines offer the versatility required to fulfill a variety of cutting and shaping needs.

The ability to customize products not only enhances customer satisfaction but also opens up new revenue streams. By offering personalized and unique products, businesses can command higher prices and differentiate themselves from their competitors. Customization allows businesses to tap into niche markets and target specific customer segments, expanding their reach and profitability.

Furthermore, the versatility and customization capabilities of CNC cutting machines empower businesses to innovate and explore new possibilities. From architectural elements to art installations, businesses can push the boundaries of design and create truly exceptional pieces. CNC machines give manufacturers the freedom to experiment with different materials, shapes, and sizes, allowing for endless creative opportunities.

The combination of versatility and customization provided by CNC cutting machines gives businesses a competitive edge in the market. By being able to meet unique cutting requirements and deliver personalized products, businesses can attract a broader customer base, establish long-term relationships, and ultimately drive growth and success.

Enhanced Efficiency and Productivity

CNC cutting machines, such as premier plasma CNC machines, revolutionize business productivity by combining speed, precision, and optimized workflow. These cutting-edge machines enable businesses to meet demanding deadlines and exceed customer expectations, propelling them to new levels of success.

The remarkable speed of CNC cutting machines ensures faster turnaround times, allowing businesses to complete projects efficiently and effectively. With unmatched precision, these machines deliver accurate and precise cuts, eliminating errors and rework. This precision not only saves time but also ensures the highest quality of work.

By streamlining operations and optimizing workflow, businesses can enhance overall efficiency and exponentially increase productivity. CNC cutting machines automate processes, reducing manual errors and delays that can hinder productivity. With an optimized workflow, businesses can stay ahead of competitors and meet customer demands effectively.

Here, take a look at the comparison table below to understand the impact of CNC cutting machines on efficiency and productivity:

| Factors | Traditional Cutting Methods | CNC Cutting Machines |

|---|---|---|

| Speed | Relatively slow | Superior speed, significantly faster |

| Accuracy | Prone to human errors | Exceptional precision, minimal errors |

| Workflow | Manual processes, potential bottlenecks | Automated processes, streamlined workflow |

| Efficiency | Time-consuming, potential reworks | Optimized efficiency, reduced reworks |

| Productivity | Limited output, productivity bottlenecks | Exponential increase in productivity |

As shown in the table, CNC cutting machines outperform traditional cutting methods in every aspect, ensuring enhanced efficiency and productivity. The seamless integration of speed, precision, and optimized workflow accelerates business growth and maximizes their potential.

With the use of premier plasma CNC machines, businesses can achieve unparalleled efficiency and productivity, positioning themselves as leaders in their industries.

Unleashing Creativity and Innovation

CNC cutting machines provide businesses with the tools to explore new possibilities in product design and development. With the automation and versatility they offer, CNC machines revolutionize the way businesses approach creativity and innovation.

By eliminating the limitations of manual cutting methods, businesses can unleash their imagination and create without boundaries. Whether it’s complex designs or intricate metalwork, CNC machines allow for the realization of unique patterns and intricate details.

The versatility of CNC cutting machines is unparalleled, catering to various design requirements. From simple shapes to complex designs, these machines enable businesses to bring their visions to life with precision and accuracy.

Furthermore, CNC machines open up new avenues for innovation. By automating processes and streamlining workflows, businesses can allocate more time and resources to explore novel ideas and push the boundaries of traditional manufacturing.

| Benefits | Description |

|---|---|

| Endless Design Possibilities | CNC cutting machines allow businesses to create intricate and unique patterns, unlocking new design possibilities. |

| Precision and Accuracy | The automation of CNC machines ensures precise and accurate cuts, resulting in high-quality work. |

| Advanced Customization | Businesses can personalize their products and cater to individual customer needs, gaining a competitive edge in the market. |

| Efficient Workflow | By automating tasks, CNC machines streamline the manufacturing process, allowing businesses to focus on creativity and innovation. |

| Improved Efficiency | The automation and versatility of CNC machines enhance overall production efficiency, enabling businesses to meet tight deadlines and customer demands. |

The Profitability of Precision Manufacturing

Precision manufacturing, powered by CNC technology, offers numerous opportunities for profitability. By leveraging CNC machines, businesses can enhance production efficiency, leading to substantial cost savings and increased profitability. The precision and accuracy of CNC machines ensure high-quality products, resulting in customer satisfaction and brand loyalty. Additionally, the customization capabilities of CNC machines enable businesses to cater to unique customer needs, giving them a competitive edge in the market. Moreover, precision manufacturing opens doors to global market opportunities, allowing businesses to expand their reach and tap into new potential for growth and profitability.

When it comes to precision manufacturing, businesses can achieve significant cost savings. CNC machines automate industrial processes, reducing the need for manual labor and minimizing the associated labor costs. With optimized resource allocation, businesses can streamline operations and eliminate inefficiencies, further driving down costs. By implementing precision manufacturing techniques, businesses can maximize profitability while maintaining high standards of quality.

The quality of products manufactured through precision manufacturing is unparalleled. CNC machines ensure precise cuts, accurate measurements, and consistent results, leading to superior product quality. This level of precision not only meets customer expectations but also exceeds them, fostering long-term customer satisfaction and loyalty. As a result, businesses can benefit from repeat purchases and positive word-of-mouth, enhancing their profitability.

Moreover, customization plays a crucial role in the profitability of precision manufacturing. CNC machines offer the ability to create custom-designed products tailored to the specific needs of customers. This customization capability allows businesses to differentiate themselves in the market, attracting customers who value personalized solutions. By offering bespoke products, businesses can command premium prices, driving up profitability and gaining a competitive edge.

Furthermore, precision manufacturing opens up global market opportunities for businesses. With the ability to produce high-quality, customized products, businesses can tap into international markets and cater to a global customer base. This expansion into new markets not only increases sales revenue but also diversifies business risks, ensuring long-term profitability and sustainability.

Choosing the Right CNC Machine for Your Project

When embarking on a project that requires CNC machining, selecting the appropriate CNC machine is crucial to ensure optimal results. With a multitude of options available, understanding the specific project requirements is paramount in making an informed decision.

CNC milling machines are renowned for their versatility and ability to cut, drill, and shape various materials with precision. These machines are ideal for projects that demand flexibility and intricate detailing.

For projects that involve turning and shaping cylindrical or conical objects, CNC lathes are the go-to choice. These machines offer exceptional accuracy and efficiency in creating custom components.

If intricate carving, engraving, and 2D/3D machining are essential aspects of your project, CNC routers should be at the top of your list. These machines excel in delivering impeccable precision and are perfect for creating intricate designs.

When it comes to cutting thick sheets of metal, CNC plasma cutters are the industry standard. These machines guarantee clean and precise cuts, making them ideal for projects that require robust metal fabrication.

Lastly, for projects that require the creation of intricate prototypes and custom components, CNC 3D printers are a game-changer. These machines utilize additive manufacturing technology to bring your designs to life with unparalleled precision.

Ultimately, the key to selecting the right CNC machine lies in assessing the specific project requirements and desired outcomes. By considering factors such as the materials involved, intricate detailing needs, and the desired end result, businesses can make an informed decision and ensure successful project execution.