When it comes to milling hardwood, the type of milling cutter you should use depends on the type of project you are working on. For general purpose milling, a straight flute end mill is a good choice. This type of cutter is designed to cut through hardwood quickly and efficiently. It is also designed to produce a smooth finish.

For more intricate projects, a spiral flute end mill is a better choice. This type of cutter is designed to cut through hardwood more slowly, but it produces a much smoother finish. It is also better for cutting intricate shapes and patterns.

For projects that require a very smooth finish, a ball end mill is the best choice. This type of cutter is designed to cut through hardwood very slowly, but it produces a very smooth finish. It is also better for cutting intricate shapes and patterns.

Finally, for projects that require a very precise cut, a router bit is the best choice. This type of cutter is designed to cut through hardwood very slowly, but it produces a very precise cut. It is also better for cutting intricate shapes and patterns.

Can you use milling machine for wood?

Yes, you can use a milling machine for wood. Milling machines are versatile tools that can be used to shape and cut a variety of materials, including wood. They are typically used to create precise shapes and sizes, and can be used to create intricate patterns and designs. When used for woodworking, milling machines can be used to create a variety of shapes, including straight edges, curved edges, and even complex 3D shapes. They can also be used to create grooves, slots, and other features.

Milling machines are typically used in conjunction with other woodworking tools, such as routers, saws, and sanders. They can be used to create a variety of shapes and sizes, and can be used to create intricate patterns and designs. The milling machine is also used to create precise cuts and shapes, and can be used to create a variety of different types of joints.

When using a milling machine for woodworking, it is important to use the correct type of tooling and to use the correct speed and feed rate.

What kind of cutter is used to mill grooves?

A milling cutter is a type of cutting tool used in milling machines or machining centers to perform milling operations (cutting, drilling, and other operations). It is usually made of high-speed steel or cemented carbide and is available in a variety of shapes and sizes. The most common types of milling cutters are end mills, face mills, shell mills, and slot drills. End mills are used to cut grooves, slots, and other features into the workpiece. Face mills are used to cut flat surfaces, while shell mills are used to cut curved surfaces. Slot drills are used to cut slots and other features into the workpiece. All of these types of milling cutters can be used to mill grooves.

Can you CNC mill wood?

Yes, you can CNC mill wood. CNC milling is a machining process that uses computer numerical control (CNC) to control the movement of the cutting tool. This process is used to create parts with complex shapes and features from a variety of materials, including wood.

When CNC milling wood, the cutting tool is moved in three axes (X, Y, and Z) to create the desired shape. The cutting tool is usually a rotating cutting tool, such as an end mill, drill bit, or router bit. The cutting tool is moved in a precise manner, following the instructions of the CNC program. The CNC program is created using a CAD (Computer Aided Design) program, which allows the user to create a 3D model of the desired part. The CNC program is then used to control the movement of the cutting tool, which is used to cut the wood into the desired shape.

Can I mill with a drill press?

No, you cannot mill with a drill press. A drill press is designed to drill holes, while a milling machine is designed to cut and shape material. A drill press is limited in its ability to shape material, as it only has a single axis of motion, while a milling machine has multiple axes of motion and can move the material in a variety of directions. Additionally, a drill press is not designed to handle the same amount of torque as a milling machine, and therefore is not suitable for milling operations.

Why is milling important in woodworking?

Milling is an important process in woodworking because it allows for the precise shaping of wood into a desired form. It is used to create a variety of shapes, including straight edges, curved edges, and complex shapes. Milling also allows for the creation of intricate details, such as grooves, slots, and other decorative features.

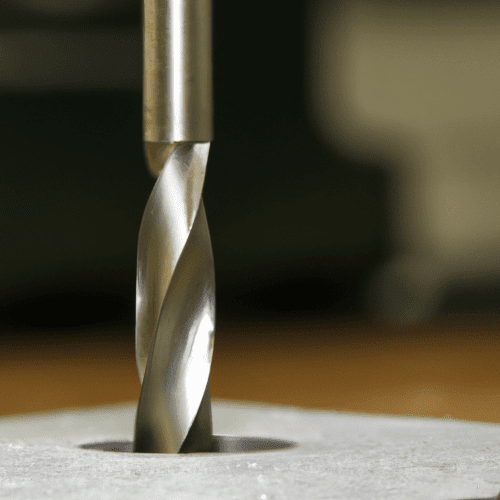

Milling is a process that involves cutting away material from a workpiece in order to create a desired shape. It is typically done with a milling machine, which is a machine tool that uses a rotating cutting tool to shape and form the workpiece. The cutting tool is usually a rotating cutter, such as a drill bit, end mill, or router bit. The milling machine is used to move the cutting tool across the workpiece in a precise manner, allowing for the creation of intricate shapes and details.

Milling is an important process in woodworking because it allows for the precise shaping of wood into a desired form. It is used to create a variety of shapes, including straight edges, curved edges, and complex shapes.

What is milling machine woodworking?

Milling machine woodworking is a process of cutting and shaping wood using a milling machine. A milling machine is a machine tool that uses a rotating cutting tool to shape and form materials such as wood. It is typically used in the manufacturing process of woodworking, and is used to create a variety of shapes and sizes. The milling machine is used to cut and shape the wood into the desired shape and size. It is also used to create intricate patterns and designs on the wood.

The milling machine is composed of several components, including a spindle, a table, a cutting tool, and a motor. The spindle is the part of the machine that rotates the cutting tool. The table is the part of the machine that holds the wood in place while the cutting tool is used to shape and form the wood. The motor is used to power the spindle and the cutting tool.

The milling machine is used to cut and shape the wood into the desired shape and size. It is used to create intricate patterns and designs on the wood.

What is milling in woodworking?

Milling in woodworking is the process of cutting and shaping wood to create a desired shape or size. It is typically done with a milling machine, which uses a rotating cutting tool to remove material from the workpiece. The cutting tool can be a router bit, saw blade, or other type of cutting tool. The milling machine can also be used to create grooves, slots, and other features in the wood. The milling process can be used to create a variety of shapes and sizes, from simple straight cuts to complex curved shapes. It is also used to create joinery, such as dovetails, mortise and tenon joints, and other types of joinery. Milling is an important part of the woodworking process, as it allows for precise and accurate cuts and shapes to be created.

What is milling machine?

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to shape and form the material into a variety of different shapes and sizes. Milling machines can be used to perform a variety of operations, including drilling, boring, reaming, tapping, and threading. They can also be used to create complex shapes and contours, as well as to cut slots and keyways. Milling machines are typically used in the manufacturing industry for the production of components and parts, as well as for the machining of large and complex parts. They are also used in the automotive, aerospace, and medical industries for the production of precision parts. Milling machines are available in a variety of sizes and configurations, and can be used for both manual and automated operations.

Can you use router bits in a milling machine?

Yes, router bits can be used in a milling machine. Router bits are designed to cut and shape wood, plastic, and other materials, and they can be used in a milling machine to do the same. Milling machines are typically used to cut metal, but they can also be used to cut softer materials such as wood and plastic. Router bits are designed to cut these softer materials, so they can be used in a milling machine to do so.

When using router bits in a milling machine, it is important to ensure that the router bit is compatible with the machine. Different router bits have different shank sizes, and the shank size must match the collet size of the milling machine. Additionally, the router bit must be able to handle the speed and power of the milling machine. If the router bit is not compatible with the milling machine, it could cause damage to the machine or the router bit.

When using router bits in a milling machine, it is also important to ensure that the router bit is sharp and in good condition.