When it comes to choosing a router for metal, there are a few important factors to consider. First, you need to determine the type of metal you will be working with. Different metals require different types of router bits, so it is important to choose a router that is compatible with the type of metal you will be working with. Additionally, you should consider the size of the router bit you will be using. If you are working with larger pieces of metal, you will need a router with a larger bit size.

Next, you should consider the power of the router. Metal is a hard material, so you will need a router with enough power to cut through it. Look for a router with a high wattage motor and variable speed settings. This will allow you to adjust the speed of the router to match the type of metal you are working with.

Finally, you should consider the features of the router. Look for a router with a dust collection system, as this will help keep your workspace clean. Additionally, look for a router with a depth stop, as this will help you control the depth of the cut.

Overall, when choosing a router for metal, it is important to consider the type of metal you will be working with, the size of the router bit, the power of the router, and the features of the router. With these factors in mind, you should be able to find a router that is suitable for your needs.

Can a router be used on aluminum?

Yes, a router can be used on aluminum. However, it is important to note that routers are designed to cut wood, and aluminum is a much harder material. Therefore, it is important to take extra precautions when using a router on aluminum. First, it is important to use a router bit specifically designed for cutting aluminum. These bits are typically made of carbide or diamond-tipped steel, and they are designed to cut through the harder material. Additionally, it is important to use a router with a variable speed control, as aluminum requires a slower speed than wood. This will help to prevent the bit from overheating and dulling. Finally, it is important to use a lubricant when cutting aluminum, as this will help to reduce friction and heat buildup.

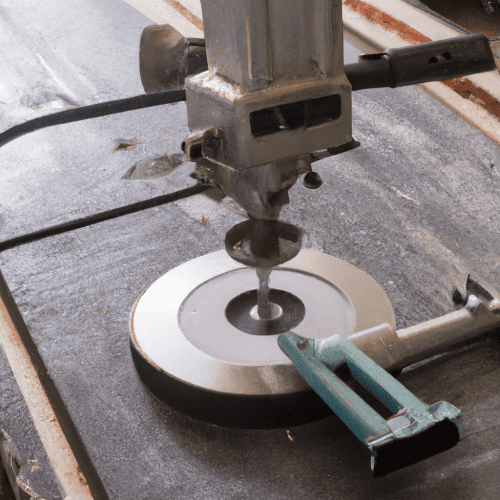

Can CNC router cut metal?

Yes, CNC routers can cut metal. CNC routers are computer-controlled machines that use a cutting tool to cut and shape materials such as wood, plastic, and metal. CNC routers are used in a variety of industries, including aerospace, automotive, and woodworking. CNC routers can be used to cut a variety of metals, including aluminum, steel, brass, and copper. The type of metal being cut will determine the type of cutting tool used. For example, aluminum is typically cut with a high-speed steel (HSS) end mill, while steel is usually cut with a carbide end mill. The cutting tool is mounted in a spindle and is driven by a motor. The cutting tool is then guided by a computer-controlled system to cut the metal to the desired shape. The cutting speed and depth of the cut can be adjusted to achieve the desired results. CNC routers can also be used to engrave metal, as well as to create 3D shapes.

Can you use a CNC machine for wood and metal?

Yes, you can use a CNC machine for both wood and metal. CNC stands for Computer Numerical Control, and it is a type of machining process that uses computer-controlled tools to shape and cut materials. CNC machines are used in a variety of industries, including woodworking, metalworking, and plastics manufacturing.

CNC machines are used to create precise shapes and sizes from a variety of materials, including wood and metal. The CNC machine is programmed with a set of instructions that tell it how to move the cutting tool in order to create the desired shape. The CNC machine can be programmed to cut a variety of shapes, including straight lines, curves, and complex shapes.

CNC machines are used in woodworking to create furniture, cabinets, and other wood products. The CNC machine can be programmed to cut the wood to the desired shape and size, and then the wood can be sanded and finished to create the desired product.

Can you use a router to cut stainless steel?

Yes, you can use a router to cut stainless steel. A router is a versatile tool that can be used to cut a variety of materials, including stainless steel. When cutting stainless steel with a router, it is important to use the right type of router bit and to use the correct cutting speed and feed rate. The type of router bit you use will depend on the thickness of the stainless steel you are cutting and the type of cut you are making. For example, if you are making a straight cut, you will need a straight router bit. If you are making a curved cut, you will need a curved router bit. It is also important to use the correct cutting speed and feed rate. The cutting speed should be slow enough to prevent the router bit from overheating, and the feed rate should be slow enough to prevent the router bit from stalling. Additionally, it is important to use a lubricant when cutting stainless steel with a router to reduce friction and heat buildup.

Can CNC router cut brass?

Yes, CNC routers can cut brass. CNC routers are computer-controlled machines that use a cutting tool to cut and shape materials. They are commonly used to cut and shape wood, plastic, and metal. Brass is a metal alloy made up of copper and zinc, and it is a popular material for machining and cutting. CNC routers can be used to cut brass into a variety of shapes and sizes. The cutting tool used for brass is typically a high-speed steel or carbide-tipped tool. The cutting speed and feed rate will depend on the type of brass being cut and the size of the material. The cutting tool should be sharp and the cutting speed should be adjusted to the hardness of the brass. The cutting tool should also be lubricated to reduce friction and heat buildup. The cutting tool should be changed regularly to ensure a clean cut and to prevent damage to the brass. The CNC router should also be set up properly to ensure a smooth and accurate cut.

Can you cut stainless steel on a CNC router?

Yes, you can cut stainless steel on a CNC router. CNC routers are computer-controlled machines that are used to cut and shape materials such as wood, plastic, and metal. CNC routers are capable of cutting stainless steel, as long as the right tools and settings are used. The type of tool used to cut stainless steel on a CNC router will depend on the thickness of the material and the desired finish. For thin stainless steel, a high-speed steel (HSS) end mill is typically used. For thicker stainless steel, a carbide end mill is usually the best choice. The cutting speed and feed rate should also be adjusted to ensure a clean cut and to prevent the tool from becoming dull or damaged. Additionally, the use of a lubricant or coolant is recommended to reduce heat buildup and to help extend the life of the tool.

Can you use a CNC on metal?

Yes, you can use a CNC (Computer Numerical Control) machine on metal. CNC machines are automated milling devices that make use of computer-programmed commands to cut and shape a variety of materials, including metal. CNC machines are used in a variety of industries, including automotive, aerospace, and medical, to create precision parts and components.

CNC machines are capable of cutting and shaping metal with a high degree of accuracy and repeatability. The machine is programmed with a set of instructions that tell it how to move the cutting tool in order to create the desired shape. The cutting tool is usually a rotating cutting tool, such as a drill bit, end mill, or router bit. The cutting tool is moved along the X, Y, and Z axes in order to create the desired shape.