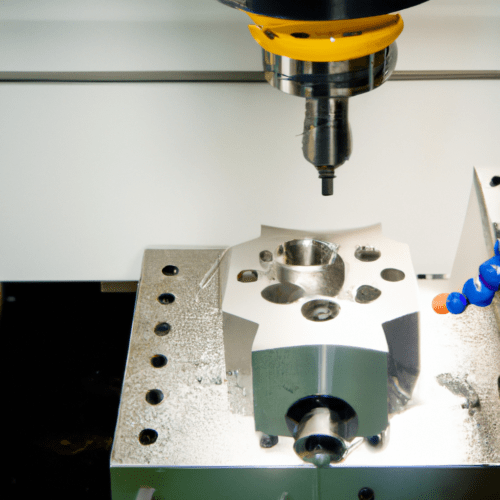

As humanity continues its quest to explore the vast cosmos, space exploration has become one of the most ambitious and promising endeavors of our time. Technological advancements play a pivotal role in propelling space exploration forward, and one such crucial technology is Computer Numerical Control (CNC) machining. CNC machining has revolutionized manufacturing on Earth, and now it is poised to revolutionize space exploration. In this blog, we will explore the challenges and opportunities that CNC machining presents in the context of space exploration.

The Role of CNC Machining in Space Exploration

The application of CNC machining in space exploration is multi-faceted, encompassing satellite production, spacecraft development, and even interplanetary missions. Here are some key areas where CNC machining plays a significant role:

A. Satellite Construction: Satellites are critical components of space missions, used for communication, weather monitoring, Earth observation, and scientific research. CNC machining enables the production of lightweight, high-strength satellite components that can withstand the rigors of space travel.

B. Spacecraft Components: CNC machining is essential for the production of intricate and complex components in spacecraft, such as thrusters, heat shields, and landing gear. These components need to be precise, reliable, and durable to ensure mission success.

C. Additive Manufacturing in Space: With the advancement of additive manufacturing (3D printing) techniques, CNC machines can now fabricate parts using various materials, even in the harsh environment of space. This capability is invaluable for on-demand repairs and creating spare parts during extended missions.Challenges in CNC Machining for Space Exploration

While CNC machining presents numerous opportunities for space exploration, it also faces unique challenges

A. Weight and Space Constraints: Space missions demand lightweight and compact components to reduce fuel consumption and increase payload capacity. CNC machines used for space applications must be compact, yet powerful, with minimal material wastage.

B. Radiation Hardening: In space, electronic components are exposed to ionizing radiation, which can degrade performance and cause malfunctions. CNC machines used in space must be radiation-hardened to maintain reliable operation.

C. Remote Manufacturing: For deep-space missions, the time delay in communication poses challenges for remote control. Developing autonomous CNC systems capable of performing complex tasks without human intervention becomes essential.

D. Material Limitations: CNC machining traditionally relies on a wide range of materials. However, space exploration requires components that can withstand extreme temperatures, vacuum conditions, and cosmic radiation, limiting the choice of materials.

Opportunities in CNC Machining for Space Exploration

Despite the challenges, CNC machining offers significant opportunities for space exploration:

A. In-Situ Resource Utilization (ISRU): CNC machines can be used alongside robotic systems to process and utilize resources found on celestial bodies, such as the Moon or Mars. This concept, known as ISRU, enables self-sufficiency for extended missions.

B. Rapid Prototyping: CNC machining allows for rapid prototyping of mission-critical components, enabling iterative design improvements and reducing development time.

C. Cost Reduction: By manufacturing components in space instead of transporting them from Earth, the cost of space missions can be significantly reduced. CNC machines can contribute to cost-effectiveness by providing in-orbit manufacturing capabilities.

D. Space Colonization: As humanity’s aspirations extend beyond Earth, CNC machining will be vital for building habitats, infrastructure, and tools for sustaining life on other planets.

Facts you may not know

- Space exploration heavily relies on CNC machining for manufacturing components used in rockets, satellites, space vehicles, and scientific instruments.

- The extreme conditions of space, such as vacuum, extreme temperatures, and radiation, pose unique challenges for CNC machining in space exploration.

- One significant challenge is designing CNC machines that can operate efficiently in zero-gravity environments, where traditional machining techniques may not be effective.

- NASA and other space agencies are exploring the use of additive manufacturing (3D printing) alongside CNC machining to overcome weight limitations and create complex geometries with minimal waste.

- CNC machining in space requires careful consideration of the materials used, as certain metals may behave differently in space due to the lack of gravity and the presence of radiation.

- To optimize the machining process, space missions may employ autonomous CNC systems that can adjust to changing conditions and ensure precision without human intervention.

- Repairs and maintenance of space equipment are often performed using CNC machining on the International Space Station (ISS) and future space habitats.

- CNC machining in space exploration opens up opportunities for in-situ resource utilization (ISRU), where lunar or Martian regolith could be used to create necessary parts or structures.

- Miniaturization of CNC machines is a growing trend for space missions, as smaller machines can be more easily transported and deployed in space for localized manufacturing.

- The integration of artificial intelligence and machine learning with CNC machining in space can lead to real-time adaptive control, predictive maintenance, and improved overall efficiency.

- Successful CNC machining in space exploration could pave the way for sustainable and cost-effective long-duration space missions by reducing the reliance on Earth for resupplying spare parts and components.

What are some companies who use CNC machining in there components for space exploration?

- Blue Origin: Founded by Jeff Bezos, Blue Origin is a private aerospace manufacturer and spaceflight services company. They have been involved in developing technologies for space exploration, including CNC machining of critical components for their spacecraft.

- SpaceX: Founded by Elon Musk, SpaceX is a private aerospace manufacturer and space transportation company. They have utilized CNC machining extensively for their rockets, including the Falcon 9 and Falcon Heavy, as well as the spacecraft like Dragon and Starship.

- Rocket Lab: Rocket Lab is a private aerospace manufacturer and small satellite launch service provider. They focus on small payload launches and have used CNC machining in their rocket development.

- Orbital ATK/Northrop Grumman: Now part of Northrop Grumman Innovation Systems, this company has been involved in space exploration and satellite manufacturing. They have utilized CNC machining for various components in their projects.

- NASA’s Marshall Space Flight Center: While not a private company, NASA’s Marshall Space Flight Center has been involved in space exploration research and development, including CNC machining of components for their spacecraft.

- Boeing: Boeing is a well-known aerospace company that has been involved in various space exploration projects, including the manufacture of components using CNC machining techniques.

- Lockheed Martin: Lockheed Martin is another major aerospace and defense company that has been involved in space exploration missions and has used CNC machining for critical components.

- Airbus Defence and Space: Airbus Defence and Space is part of Airbus Group and is involved in space-related projects, including CNC machining for space exploration missions.

Please note that the landscape of companies involved in space exploration and CNC machining is continually evolving, and there may be new players or changes in the status of the companies listed above since my last update. It’s always best to check the latest information to get the most up-to-date details.

Future Prospects and Conclusion

The future of space exploration is undeniably intertwined with CNC machining technology. As we venture into deeper space, overcoming the challenges and leveraging the opportunities presented by CNC machining will be paramount. Research and development efforts must focus on miniaturizing CNC machines, enhancing their autonomy, and exploring novel materials to ensure their reliability and effectiveness in the harsh conditions of space.

The collaboration between aerospace engineers, materials scientists, and CNC machining experts will be vital in developing cutting-edge solutions for the challenges of space exploration. By harnessing the full potential of CNC machining, we will unlock new frontiers, make groundbreaking discoveries, and lay the foundation for humanity’s long-term presence beyond our home planet.

In conclusion, CNC machining represents a crucial technology for space exploration, presenting both challenges and opportunities. By addressing these challenges and capitalizing on the opportunities, we can propel space exploration to new heights, advancing human knowledge and expanding our presence in the cosmos. Together, we can turn the dreams of interplanetary travel and space colonization into a tangible reality.