A machinist’s tool set is an essential collection of tools for any professional or hobbyist machinist. It’s important to have the right tools for the job, and the necessary components of a machinist’s tool set will vary depending on the type of work being done. The following is a list of essential items that should be included in any machinist’s tool set:

1. Hand Tools: These are the most commonly used tools for machining and include a variety of wrenches, hammers, pliers, screwdrivers, and other hand tools.

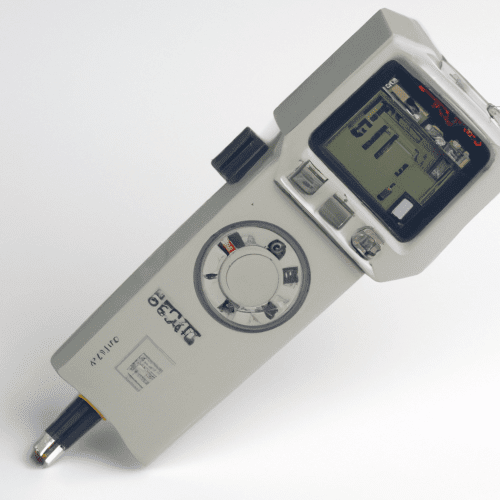

2. Precision Measuring Instruments: This includes calipers, micrometers, depth gauges, and other precision measuring instruments.

3. Cutting Tools: There are several different types of cutting tools including drill bits, taps, reamers, and end mills.

4. Clamping Fixtures: These are used to secure work pieces in place while machining.

5. Machine Parts: These are the parts that make up the machine, such as bearings, shafts, gears, pulleys, and other components.

6. Lubricants and Fluids: These include lubricants for the machine as well as cutting fluids for machining operations.

7. Files and Grinding Stones: These are used to shape and finish the workpiece.

8. Safety Equipment: This includes safety glasses, face shields, gloves, and other protective gear. Having the right tools for the job is essential for any machinist, and having the necessary components of a machinist’s tool set will help ensure that the job is done correctly and efficiently.

Understanding the Different Types of Machinist Tools

Machinists are professionals who use a variety of tools to shape and cut metal or other materials. Depending on the task, the machinist may use a range of tools from hand tools to power tools to complete the job. It is important to understand the different types of machinist tools and how they are used in order to use them properly and safely. Hand Tools: Hand tools are the most basic tools a machinist will use. These tools include wrenches, chisels, files, hammers, pliers, punches, and screwdrivers. Hand tools are used for a variety of tasks such as drilling, cutting, shaping, and grinding. Power Tools: Power tools are more powerful and efficient than hand tools. They are used to speed up production and increase accuracy. Power tools include lathes, milling machines, drill presses, saws, and grinders.

Measuring Tools: Measuring tools are used to measure the size and shape of parts. Common measuring tools include calipers, micrometers, rulers, and gauges. Cutting Tools: Cutting tools are used to cut through metal or other materials. They include drills, taps, dies, reamers, and saws. These are the main types of machinist tools. Depending on the task, the machinist may use a combination of hand tools, power tools, measuring tools, and cutting tools. It is important to understand the different types of tools available and how to use them properly and safely in order to be successful in the machining industry.

Exploring the Benefits of Investing in Quality Machinist Tools

Investing in quality machinist tools is an important decision for any machinist, as these tools are a vital component of the work that they do. Quality machinist tools are an investment that can pay off in many ways, from improved safety to increased efficiency. In this article, we will explore the various benefits of investing in quality machinist tools. The first benefit of investing in quality machinist tools is improved safety. Machinists rely on their tools to complete their work safely and accurately. If a machinist is using inferior tools, they may be putting themselves at risk of injury due to the inferior construction of the tools. Quality machinist tools are designed with safety in mind, and are built to last, meaning that the machinist can trust in their tools to complete their work safely. The second benefit of investing in quality machinist tools is increased efficiency.

Quality machinist tools are precision instruments designed to give the machinist the most accurate results possible. This accuracy and precision can help the machinist to complete their work faster and more accurately, leading to improved job performance and increased productivity. The third benefit of investing in quality machinist tools is durability. Quality machinist tools are built to last, so the machinist does not have to worry about replacing their tools frequently. This ultimately leads to cost savings, as the machinist will not have to invest in new tools as often. Finally, investing in quality machinist tools can lead to greater job satisfaction. Quality machinist tools provide the machinist with the confidence that their work is of the highest quality.

This can lead to greater job satisfaction, as the machinist knows that their work is of the highest standard. In conclusion, investing in quality machinist tools can provide many benefits to the machinist, including improved safety, increased efficiency, durability, and greater job satisfaction. Quality machinist tools are an important investment for any machinist, and the benefits of making this investment can be substantial.

How to Choose the Right Machinist Tool for Your Project

Whether you are a hobbyist or a professional machinist, having the right machinist tools is essential for your project. Choosing the appropriate tool for your specific task can make the difference between success and failure. It is important to understand the purpose of each tool and the type of material that it is designed to work with. The first step in choosing the right machinist tool is to identify the type of metal or material that you will be working with. This is important in order to select the correct cutting tools, measuring tools, and other accessories. Different metals and materials have different hardness levels, which can affect the performance of the tool.

Steel, for example, is generally harder than aluminum and requires specific tools to work with. Once you have identified the material, you can select the appropriate tool. Consider the size and shape of the part you will be working on and the type of process you will be using to complete the task. If you are drilling a hole, for example, you will need a drill bit designed specifically for the material you are working with. If you are cutting, you will need a saw, grinding wheel, or milling machine. Finally, consider the accuracy and quality of the machinist tool. Look for tools that are designed with precision in mind. Quality tools can make the difference between a successful project and an unsuccessful one. Consider both the price and the reputation of the tool manufacturer before making a purchase.

Choosing the right machinist tool is an important part of any project. Taking the time to research the material and process you will be working with, as well as the accuracy and quality of the tools you select, can help ensure success.

Machinist Tool Safety: Tips for Using Machinist Tools Safely

When using machinist tools, it is important to take safety precautions to avoid accidents and injury. The following tips will help ensure the safe use of machinist tools: • Wear appropriate safety gear. When using machinist tools, always wear safety glasses, hearing protection, and other protective clothing and gear as necessary.

- Read and understand all instructions. Before using machinist tools, make sure to read and understand the instructions and safety warnings associated with the tool.

- Use the correct tool. Make sure to use the correct tool for the job, and do not use a tool for a task that it was not designed for.

- Check for proper setup. Before beginning a job, check that the machine is set up correctly and that the tools are in good condition and properly secured.

- Keep tools sharp. Dull tools are more dangerous and can cause kickbacks and other injuries. • Maintain control. Always keep your hands away from the point of operation and other moving parts of the machine, and never reach over the cutting tool.

- Keep the work area clean. Make sure the work area is free of clutter and that all tools and materials are organized and stowed away properly.

- Be aware of the surroundings. Be aware of your surroundings when operating the machine, and make sure all other personnel are clear of the machine. By following these safety tips, you can help ensure the safe use of machinist tools. Taking the necessary precautions can help prevent accidents and injury.

How to Maintain and Care for Your Machinist Tools

Machinist tools are essential pieces of equipment for any workshop or garage. Whether you are an experienced machinist or just beginning, proper maintenance and care of your tools will help ensure your projects are completed accurately and on time. Taking the time to practice proper maintenance and care for your machinist tools will extend the life of your tools and help prevent costly repairs or replacement. First, it is important to keep your tools clean and in good condition. After each use, be sure to clean any dirt or debris off of your tools and store them in a designated area away from moisture and dust. To prevent rusting, apply a light coating of oil to your tools before storing.

Second, inspect all of your machinist tools regularly for signs of wear and tear, such as cracks, chips, or dents. If any of these problems are found, replace the tool immediately. It is also important to check for loose or worn parts and replace these as well.

Third, sharpen your tools regularly. Dull blades or cutters can cause excess wear and tear on your tools and can make your projects more difficult to complete. To sharpen your tools, use a sharpening stone or an electric sharpener. Be sure to follow the manufacturer’s instructions for use.

Finally, lubricate your machinist tools regularly. This will help to reduce friction and wear on the moving parts of your tools. Apply a thin layer of lubricant to the moving parts of your tools and wipe off any excess. By following these simple tips, you can ensure your machinist tools will be in top condition and last for years to come. Taking the time to properly maintain and care for your tools will save you time and money in the long run.