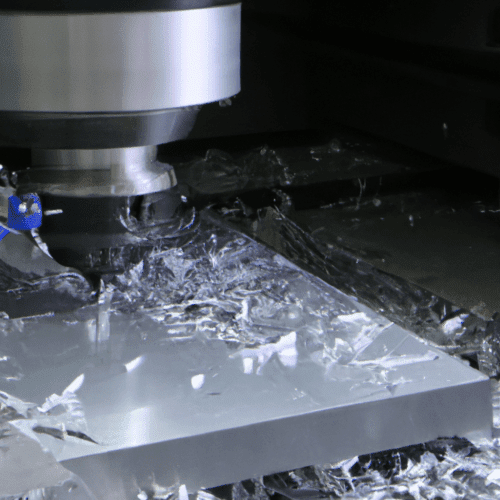

Yes, a CNC machine can cut aluminum. CNC stands for Computer Numerical Control, and it is a type of machining process that uses computer-controlled tools to cut and shape materials. CNC machines are used to cut a variety of materials, including aluminum. The process of cutting aluminum with a CNC machine involves using a cutting tool, such as a drill bit, to cut the aluminum into the desired shape. The cutting tool is attached to the CNC machine and is programmed to move in a specific pattern to cut the aluminum. The CNC machine is then able to cut the aluminum with precision and accuracy.

The type of cutting tool used to cut aluminum with a CNC machine depends on the type of aluminum being cut. For example, softer aluminum can be cut with a drill bit, while harder aluminum may require a router bit or end mill. The cutting tool is also chosen based on the desired finish of the aluminum. For example, a drill bit may be used to create a rough finish, while a router bit or end mill may be used to create a smoother finish.

The speed and accuracy of the CNC machine also affects the quality of the cut. The speed of the CNC machine is determined by the type of cutting tool being used and the type of aluminum being cut. The accuracy of the CNC machine is determined by the programming of the machine and the quality of the cutting tool.

In conclusion, a CNC machine can be used to cut aluminum. The type of cutting tool used, the speed of the CNC machine, and the accuracy of the CNC machine all affect the quality of the cut.

Can you cut aluminum with a CNC?

Yes, you can cut aluminum with a CNC (Computer Numerical Control) machine. CNC machines are used to cut and shape a variety of materials, including aluminum. The process of cutting aluminum with a CNC machine involves using a cutting tool, such as a drill bit, to cut the aluminum into the desired shape. The cutting tool is attached to the CNC machine and is programmed to move in a specific pattern to cut the aluminum. The CNC machine is then able to precisely cut the aluminum into the desired shape.

The type of cutting tool used to cut aluminum with a CNC machine depends on the type of aluminum being cut. For example, softer aluminum can be cut with a drill bit, while harder aluminum may require a router bit. The cutting tool is also chosen based on the desired finish of the aluminum. For example, a drill bit may be used to create a rough finish, while a router bit may be used to create a smoother finish.

The speed and accuracy of the CNC machine also affects the quality of the cut. The speed of the CNC machine is determined by the type of cutting tool used and the type of aluminum being cut. The accuracy of the CNC machine is determined by the programming of the machine and the quality of the cutting tool.

In conclusion, yes, you can cut aluminum with a CNC machine. The type of cutting tool used, the speed of the CNC machine, and the accuracy of the CNC machine all affect the quality of the cut.

What type of cutter is used for milling aluminum?

Milling aluminum requires a specific type of cutter to ensure that the material is cut properly and efficiently. The most common type of cutter used for milling aluminum is an end mill. End mills are designed with flutes that spiral around the cutting edge, allowing for efficient chip removal and a smooth finish. End mills are available in a variety of sizes and shapes, including square, ball, and corner radius, and can be used for a variety of operations, including face milling, shoulder milling, and slotting. Additionally, end mills can be used for both roughing and finishing operations. When selecting an end mill for milling aluminum, it is important to consider the material’s hardness, the depth of the cut, and the desired finish. For example, a high-speed steel end mill is best suited for softer aluminum alloys, while a carbide end mill is better suited for harder aluminum alloys. Additionally, a coated end mill is recommended for aluminum alloys that are prone to galling or welding.

Can my CNC cut metal?

Yes, CNC machines can cut metal. CNC stands for Computer Numerical Control, and it is a type of machining process that uses computer-controlled cutting tools to shape and cut materials. CNC machines are used in a variety of industries, including automotive, aerospace, and medical, and they are capable of cutting a wide range of materials, including metal.

The type of metal that a CNC machine can cut depends on the type of machine and the cutting tools that are used. Generally, CNC machines are capable of cutting softer metals such as aluminum, brass, and copper. For harder metals such as steel and titanium, a CNC machine with a higher power output and specialized cutting tools is required.

When cutting metal with a CNC machine, the cutting tools must be sharp and the cutting speed must be adjusted to the type of metal being cut. The cutting speed should be slow enough to ensure that the cutting tools do not overheat and become dull. Additionally, the cutting tools must be lubricated to reduce friction and heat buildup.

CNC machines are also capable of performing other operations on metal, such as drilling, tapping, and milling. These operations can be used to create complex shapes and parts from metal.

Overall, CNC machines are capable of cutting metal, and the type of metal that can be cut depends on the type of machine and the cutting tools that are used. It is important to ensure that the cutting tools are sharp and that the cutting speed is adjusted to the type of metal being cut. Additionally, the cutting tools must be lubricated to reduce friction and heat buildup.

How much does CNC milling cost?

The cost of CNC milling depends on a variety of factors, including the size and complexity of the part being machined, the material being used, the number of parts being produced, and the type of CNC milling machine being used. Generally speaking, CNC milling can range from a few hundred dollars for a simple part to tens of thousands of dollars for a complex part. The cost of CNC milling also depends on the type of machining being done, such as 3-axis, 4-axis, or 5-axis machining. 3-axis machining is the most basic type of CNC milling and is typically the least expensive, while 5-axis machining is the most complex and is usually the most expensive. Additionally, the cost of CNC milling can be affected by the type of tooling being used, the speed of the machine, and the complexity of the programming.

The cost of CNC milling can also be affected by the number of parts being produced. If a large number of parts are being produced, the cost per part can be significantly reduced. Additionally, the cost of CNC milling can be reduced by using a more efficient machine, such as a high-speed spindle, or by using a more efficient programming language.

Overall, the cost of CNC milling can vary greatly depending on the size and complexity of the part being machined, the material being used, the number of parts being produced, the type of CNC milling machine being used, the type of tooling being used, the speed of the machine, and the complexity of the programming.

Can you machine aluminum with a CNC router?

Yes, you can machine aluminum with a CNC router. CNC routers are computer-controlled machines that are used to cut and shape materials such as wood, plastic, and metal. Aluminum is a popular material to machine with a CNC router because it is lightweight, strong, and corrosion-resistant. When machining aluminum with a CNC router, it is important to use the correct cutting tools and speeds to ensure a quality finish. The cutting tools should be made of high-speed steel or carbide and should be sharpened regularly. The cutting speed should be adjusted based on the material being machined and the type of tool being used. Additionally, the feed rate should be adjusted to ensure that the cutting tool does not become overloaded. It is also important to use a lubricant when machining aluminum to reduce friction and heat buildup. Finally, it is important to use the correct cutting parameters to ensure that the aluminum is machined correctly and that the finished product meets the desired specifications.

Can you machine aluminum with a router?

Yes, you can machine aluminum with a router. Routers are versatile tools that can be used to cut, shape, and finish a variety of materials, including aluminum. When machining aluminum with a router, it is important to use the right type of router bit and to take the necessary safety precautions.

The type of router bit you use will depend on the type of aluminum you are machining and the desired finish. For example, if you are machining aluminum for a decorative purpose, you may want to use a carbide-tipped router bit. If you are machining aluminum for a structural purpose, you may want to use a high-speed steel router bit. It is also important to use a router bit that is designed for aluminum, as other types of router bits may not be suitable for machining aluminum.

When machining aluminum with a router, it is important to take the necessary safety precautions. This includes wearing safety glasses and a dust mask to protect yourself from flying debris, and using a router table to ensure that the router is stable and secure. Additionally, it is important to use a router bit that is sharp and in good condition, as dull or damaged router bits can cause the aluminum to tear or chip.

Overall, routers are a great tool for machining aluminum, as long as the right type of router bit is used and the necessary safety precautions are taken.

What is the difference between a CNC router and a CNC mill?

The primary difference between a CNC router and a CNC mill is the type of cutting tool they use. A CNC router typically uses a spinning router bit to cut materials, while a CNC mill uses a rotating end mill to cut materials. CNC routers are generally used for cutting softer materials such as wood, plastic, and foam, while CNC mills are used for cutting harder materials such as metal and aluminum.

CNC routers are also typically smaller and more lightweight than CNC mills, making them easier to move and transport. CNC routers are also typically less expensive than CNC mills, making them a more cost-effective option for smaller projects.

CNC routers are also typically easier to use than CNC mills, as they require less setup and programming. CNC routers are also typically more accurate than CNC mills, as they are able to cut more precise shapes and patterns.

In terms of speed, CNC mills are typically faster than CNC routers, as they are able to cut harder materials more quickly. CNC mills are also able to cut deeper into materials than CNC routers, making them better suited for larger projects.

Overall, CNC routers and CNC mills are both powerful tools that can be used to create a variety of products. The type of tool you choose will depend on the type of material you are cutting, the size of the project, and the accuracy and speed you need.

How much does CNC milling cost?

The cost of CNC milling depends on a variety of factors, including the size and complexity of the part being machined, the material being used, the number of parts being produced, and the type of CNC milling machine being used. Generally speaking, CNC milling can range from a few hundred dollars for a simple part to tens of thousands of dollars for a complex part. The cost of CNC milling also depends on the type of machining being done, such as 3-axis, 4-axis, or 5-axis machining. 3-axis machining is the most basic type of CNC milling and is typically the least expensive, while 5-axis machining is the most complex and is usually the most expensive. Additionally, the cost of CNC milling can be affected by the type of tooling being used, the speed of the machine, and the complexity of the programming.

The cost of CNC milling can also be affected by the number of parts being produced. If a large number of parts are being produced, the cost per part can be significantly reduced. Additionally, the cost of CNC milling can be reduced by using a more efficient machine, such as a high-speed spindle, or by using a more efficient programming language.

Overall, the cost of CNC milling can vary greatly depending on the size and complexity of the part being machined, the material being used, the number of parts being produced, the type of CNC milling machine being used, the type of tooling being used, the speed of the machine, and the complexity of the programming.

Why is aluminum easier to machine?

Aluminum is easier to machine than other metals because it is a soft metal with a low melting point. This makes it easier to cut and shape with tools such as drills, lathes, and milling machines. Aluminum is also lightweight and has a low density, which makes it easier to handle and manipulate. Additionally, aluminum has a low coefficient of friction, which means that it is less likely to stick to the cutting tool and cause it to wear out quickly. Finally, aluminum is highly corrosion resistant, which means that it can be machined without the need for additional lubrication or protective coatings. All of these factors make aluminum an ideal material for machining.

How do you CNC Aluminium?

CNC machining aluminum is a process that involves the use of computer numerical control (CNC) machines to shape and cut aluminum into a desired shape or design. The process begins with the selection of the right type of aluminum for the job. Depending on the desired shape or design, the aluminum may need to be anodized, heat treated, or otherwise treated to achieve the desired properties. Once the aluminum is selected, it is then loaded into the CNC machine. The CNC machine is programmed with the desired shape or design, and the aluminum is cut to the exact specifications. The CNC machine is then used to cut the aluminum into the desired shape or design.

The cutting process is done using a variety of tools, such as end mills, drills, and routers. The tools are chosen based on the type of aluminum being cut and the desired shape or design. The tools are then used to cut the aluminum into the desired shape or design. The cutting process is done with precision and accuracy, and the aluminum is cut to exact specifications.

Once the aluminum is cut, it is then finished. Finishing processes may include sanding, polishing, anodizing, or painting. The finishing process is done to give the aluminum a desired look and feel. The finished aluminum is then ready for use in a variety of applications.

CNC machining aluminum is a precise and accurate process that can be used to create a variety of shapes and designs. The process is relatively simple and can be done quickly and efficiently. With the right tools and materials, CNC machining aluminum can be used to create a variety of products and components.

What metals can a CNC router cut?

A CNC router is a computer-controlled cutting machine used to cut a variety of materials, including metals. The type of metal that a CNC router can cut depends on the type of router and the type of cutting tool used. Generally, CNC routers can cut a variety of metals, including aluminum, brass, copper, steel, and titanium.

Aluminum is a lightweight metal that is often used in the aerospace and automotive industries. It is relatively easy to cut with a CNC router, as it is a soft metal. CNC routers can be used to cut aluminum into intricate shapes and designs.

Brass is a strong metal that is often used in the construction and plumbing industries. It is a bit more difficult to cut than aluminum, but it can still be done with a CNC router.

Copper is a soft metal that is often used in the electrical and plumbing industries. It is relatively easy to cut with a CNC router, as it is a soft metal.

Steel is a strong metal that is often used in the construction and automotive industries. It is more difficult to cut than aluminum or brass, but it can still be done with a CNC router.

Titanium is a strong metal that is often used in the aerospace and medical industries. It is more difficult to cut than aluminum, brass, or steel, but it can still be done with a CNC router.

In addition to these metals, CNC routers can also be used to cut a variety of other materials, such as wood, plastic, and foam. The type of material that a CNC router can cut depends on the type of router and the type of cutting tool used.

Can you use a CNC machine for wood and metal?

Yes, you can use a CNC machine for both wood and metal. CNC stands for Computer Numerical Control, and it is a type of automated machining process that uses computer-controlled commands to cut and shape materials. CNC machines are used in a variety of industries, including woodworking, metalworking, and plastics manufacturing.

CNC machines are capable of cutting and shaping both wood and metal materials. For woodworking, CNC machines are used to create intricate designs and shapes, such as furniture, cabinetry, and musical instruments. For metalworking, CNC machines are used to create parts for cars, airplanes, and other machinery.

CNC machines are highly precise and can be programmed to cut and shape materials with great accuracy. They are also capable of producing complex shapes and designs that would be difficult or impossible to achieve with traditional machining methods.

CNC machines are also relatively easy to use and require minimal setup time. They can be programmed to cut and shape materials with a variety of tools, such as routers, drills, and saws. This makes them ideal for both large-scale and small-scale projects.

Overall, CNC machines are a great tool for both woodworking and metalworking. They are highly precise, easy to use, and capable of producing complex shapes and designs.