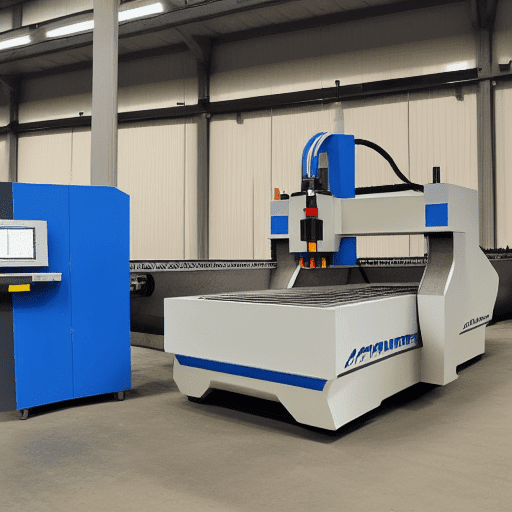

Yes, a CNC mill can be used to mill steel. CNC stands for Computer Numerical Control, and it is a type of machining process that uses computer-controlled cutting tools to shape and cut materials. CNC mills are used to cut a variety of materials, including steel, aluminum, brass, and plastic.

When it comes to milling steel, CNC mills are capable of producing precise and intricate shapes with a high degree of accuracy. The CNC milling process involves the use of a computer-controlled cutting tool, such as a drill bit, to shape and cut the steel. The cutting tool is programmed to move in a specific pattern, and the computer controls the speed and direction of the cutting tool. This allows for precise and accurate cuts.

CNC mills are also capable of producing complex shapes and intricate details. This is because the cutting tool can be programmed to move in a variety of directions and at different speeds. This allows for the creation of complex shapes and intricate details that would be difficult to achieve with traditional machining methods.

CNC mills are also capable of producing parts with a high degree of accuracy and repeatability. This is because the cutting tool is programmed to move in a specific pattern, and the computer controls the speed and direction of the cutting tool. This allows for precise and accurate cuts, which can be repeated over and over again.

Overall, CNC mills are capable of producing precise and intricate shapes with a high degree of accuracy and repeatability. This makes them ideal for milling steel, as they are capable of producing complex shapes and intricate details with a high degree of accuracy.

Can you use a CNC machine for wood and metal?

Yes, you can use a CNC machine for both wood and metal. CNC stands for Computer Numerical Control, and it is a type of automated machining process that uses computer-controlled commands to cut and shape materials. CNC machines are used in a variety of industries, including woodworking, metalworking, and plastics manufacturing.

CNC machines are capable of cutting and shaping both wood and metal materials. For woodworking, CNC machines are used to create intricate designs and shapes, such as furniture, cabinetry, and musical instruments. For metalworking, CNC machines are used to create parts for cars, airplanes, and other machinery.

CNC machines are highly precise and can be programmed to cut and shape materials with great accuracy. They are also capable of producing complex shapes and designs that would be difficult or impossible to achieve with traditional machining methods.

CNC machines are also relatively easy to use and require minimal setup time. They can be programmed to cut and shape materials with a variety of tools, such as routers, drills, and saws. This makes them ideal for both large-scale and small-scale projects.

Overall, CNC machines are a great tool for both woodworking and metalworking. They are highly precise, easy to use, and capable of producing complex shapes and designs.

Can routers cut metal?

No, routers cannot cut metal. Routers are woodworking tools that are used to cut and shape wood, plastic, and other soft materials. They are typically used to create decorative edges, hollow out an area in the middle of a piece of wood, or create grooves and slots. Routers are not designed to cut metal, and attempting to do so can cause serious damage to the router and the material being cut.

Metal cutting requires specialized tools such as saws, shears, and lathes. Saws are used to cut metal into pieces of a specific size and shape. Shears are used to cut metal into thin strips or sheets. Lathes are used to shape metal into round or cylindrical shapes. Each of these tools is designed to cut metal and can do so safely and efficiently.

In summary, routers are not designed to cut metal and attempting to do so can cause serious damage to the router and the material being cut. Metal cutting requires specialized tools such as saws, shears, and lathes.

What kind of CNC machine cuts metal?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. CNC machines are used to cut and shape a variety of materials, including metal. CNC machines that are used to cut metal typically use a rotating cutting tool, such as a drill bit, end mill, or router bit, to remove material from the workpiece. The cutting tool is mounted on a spindle, which is driven by a motor. The motor is controlled by the CNC machine’s computer program, which is programmed to move the cutting tool in a specific pattern or along a specific path. The cutting tool is also fed into the workpiece at a specific rate, which is determined by the CNC machine’s computer program. The cutting tool is then moved in a specific pattern or along a specific path to cut the metal. The CNC machine can also be programmed to perform other operations, such as drilling, tapping, and reaming.

How thick steel can laser cut?

Laser cutting is a process that uses a focused beam of light to cut through materials such as steel. The thickness of steel that can be cut with a laser depends on the type of laser being used, the material composition of the steel, and the thickness of the steel. Generally, laser cutting is most effective for steel that is up to 1/4 inch thick. However, some lasers are capable of cutting steel up to 1 inch thick.

The type of laser used for cutting steel is typically a CO2 laser, which is a type of gas laser. This type of laser is capable of cutting through a variety of materials, including steel. The laser beam is focused on the material, and the heat generated by the beam melts the material, allowing it to be cut. The laser beam is directed by a computer-controlled system, which allows for precise cutting.

The material composition of the steel also affects the thickness that can be cut. Steel that is harder or thicker will require a more powerful laser to cut through it. Additionally, the thickness of the steel will also affect the cutting speed and the quality of the cut. Thicker steel will require a longer cutting time and may result in a less precise cut.

In conclusion, the thickness of steel that can be cut with a laser depends on the type of laser being used, the material composition of the steel, and the thickness of the steel. Generally, laser cutting is most effective for steel that is up to 1/4 inch thick, although some lasers are capable of cutting steel up to 1 inch thick.

Is CNC milling hard?

CNC milling can be a difficult process to master, but it is not necessarily hard. CNC milling is a process that involves the use of computer numerical control (CNC) machines to cut and shape materials into desired shapes and sizes. The process requires a great deal of precision and accuracy, as the machines must be programmed to cut the material in a specific way. This requires a good understanding of the CNC machine and the materials being cut.

The difficulty of CNC milling depends on the complexity of the project. Simple projects may require only basic programming and setup, while more complex projects may require more advanced programming and setup. Additionally, the type of material being cut can also affect the difficulty of the process. Harder materials may require more precise programming and setup, while softer materials may require less precision.

In addition to the programming and setup, the operator must also be familiar with the CNC machine and its safety protocols. This includes understanding the machine’s capabilities and limitations, as well as the proper use of safety equipment.

Overall, CNC milling is not necessarily hard, but it does require a good understanding of the process and the materials being cut. With the right knowledge and experience, CNC milling can be a rewarding and enjoyable experience.

What are the disadvantages of CNC?

CNC (Computer Numerical Control) is a type of automation technology that is used in a variety of industries, including manufacturing, engineering, and construction. CNC machines are used to produce parts and components with high precision and accuracy. While CNC machines offer many advantages, such as increased productivity, improved accuracy, and reduced labor costs, there are also some disadvantages associated with them.

One of the main disadvantages of CNC machines is the cost. CNC machines are expensive to purchase and maintain, and require specialized training for operators. Additionally, CNC machines require a significant amount of energy to operate, which can lead to increased energy costs.

Another disadvantage of CNC machines is that they are not as flexible as manual machines. CNC machines are programmed to perform specific tasks, and cannot be easily adapted to new tasks or processes. This can limit the range of products that can be produced with CNC machines.

CNC machines also require a significant amount of time to set up and program. This can be a major disadvantage for companies that need to produce a large number of parts in a short amount of time. Additionally, CNC machines are not suitable for producing one-off parts or prototypes, as they require a significant amount of time to program and set up.

Finally, CNC machines can be dangerous to operate, as they require the operator to be in close proximity to the machine while it is running. This can lead to potential safety hazards, such as flying debris or sparks. Additionally, CNC machines can produce a significant amount of noise, which can be a nuisance to workers and nearby residents.

What materials can you CNC?

CNC stands for Computer Numerical Control, and it is a process used to cut and shape materials with precision. The materials that can be used with CNC machines vary depending on the type of machine and the type of cutting tool being used. Generally, CNC machines can be used to cut and shape a wide variety of materials, including metals, plastics, composites, wood, and foam.

Metals are the most common material used with CNC machines. Common metals used with CNC machines include aluminum, steel, brass, copper, and titanium. CNC machines can be used to cut and shape these metals into a variety of shapes and sizes. CNC machines can also be used to drill, tap, and countersink holes in metal parts.

Plastics are also commonly used with CNC machines. Common plastics used with CNC machines include acrylic, polycarbonate, ABS, and nylon. CNC machines can be used to cut and shape these plastics into a variety of shapes and sizes. CNC machines can also be used to drill, tap, and countersink holes in plastic parts.

Composites are materials made up of two or more materials that are combined to create a new material with unique properties. Common composites used with CNC machines include carbon fiber, fiberglass, and Kevlar. CNC machines can be used to cut and shape these composites into a variety of shapes and sizes. CNC machines can also be used to drill, tap, and countersink holes in composite parts.

Wood is another material that can be used with CNC machines. Common woods used with CNC machines include oak, maple, cherry, and walnut. CNC machines can be used to cut and shape these woods into a variety of shapes and sizes. CNC machines can also be used to drill, tap, and countersink holes in wood parts.

Foam is a material that is often used with CNC machines. Common foams used with CNC machines include polyurethane foam, polystyrene foam, and expanded polystyrene foam. CNC machines can be used to cut and shape these foams into a variety of shapes

Can a router cut steel?

No, a router cannot cut steel. A router is a tool used to cut and shape wood, plastic, and other soft materials. It is not designed to cut through hard materials like steel. To cut steel, you would need to use a saw or other cutting tool specifically designed for metal. A router is not powerful enough to cut through steel, and attempting to do so could damage the router and cause injury.