1. G-code: G-code is a programming language used to control machines, such as CNC machines, in a precise and automated manner. It is the set of instructions that tells the CNC machine what actions to perform, such as controlling the speed, feed rate and path of the tool.

2. Spindle: The spindle is the rotating component of a CNC machine and is responsible for driving the cutting tool. It is usually powered by an electric motor and is capable of rotating at high speeds.

3. Feed Rate: The feed rate is the rate at which the cutting tool is fed into the material being machined. This is usually measured in inches per minute (IPM).

4. Tool Path: The tool path is the path along which the cutting tool is guided by the CNC machine. It is typically defined by G-code commands.

5. Workpiece: The workpiece is the material being machined by the CNC machine. It can be of any shape or size and can be made of various materials.

6. CAD/CAM: CAD/CAM stands for Computer-Aided Design/Computer-Aided Manufacturing. It is the process of designing and manufacturing products using computer software. This is used in CNC machining to create the necessary G-code instructions.

The Different Types of CNC Machines and Their Uses

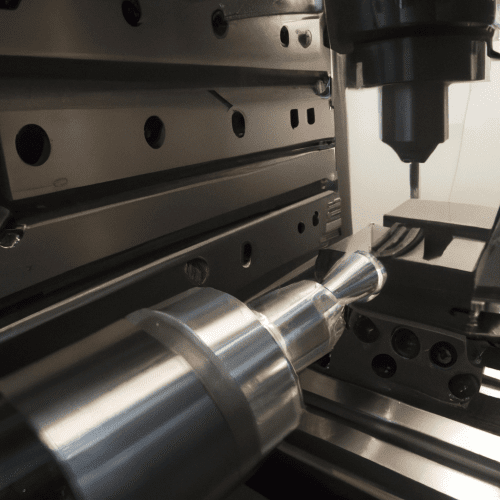

CNC machines are automated tools that are used for precision and accuracy in manufacturing processes. They are used in many industries, from aerospace and automotive to medical and woodworking. CNC stands for Computer Numerical Control and refers to the computer-controlled system that controls the machines. There are many different types of CNC machines available, each with its own unique set of capabilities and uses. One of the most popular types of CNC machines is the milling machine. Milling machines are used for cutting and shaping materials, such as metal and wood. The material is held in place with a clamping system and the cutting tools are moved with precise accuracy to cut the material into the desired shape. Milling machines can be used to make complex shapes, including slots, flat surfaces, and contours. They can also be used to create intricate patterns or to drill holes in materials.

Another type of CNC machine is a lathe. Lathes are used to shape and cut materials such as wood or metal. The material is secured in place and the cutting tools are moved around the material to create the desired shape. Lathes are often used for turning complex shapes, such as cylinders and cones. They can also be used to create intricate patterns and to drill holes in materials. CNC routers are another type of CNC machine. Routers are used to cut materials, such as wood and plastics. They are used to create intricate shapes and patterns, as well as to drill holes in materials. Routers are often used for making furniture and other products that require intricate designs. CNC plasma cutters are used to cut materials such as metal and plastics. Plasma cutters use a high-powered jet of hot gas to cut through the material, which enables them to make precise cuts with a high degree of accuracy. Plasma cutters are often used for cutting sheet metal and other materials that require intricate shapes or patterns.

CNC laser cutters are used to cut and engrave materials such as wood, plastics, and metals. Laser cutters use a focused beam of light to cut through the material with a high degree of accuracy. Laser cutters are often used for engraving and cutting intricate shapes and patterns. CNC machines are used in many industries for a variety of different tasks. They provide precision and accuracy in manufacturing processes and can be used to create complex shapes and patterns. CNC machines

How to Read CNC G-Code: A Beginner’s Guide

G-code is a programming language used to instruct computer numerical control (CNC) machines to perform a variety of tasks. It is the standard language used to communicate with CNC machines, and understanding it is essential to becoming a CNC programmer. In this guide, we will go over the basics of G-code and how to read it. The G-code syntax consists of five parts: sequence number, address letter, function letter, value, and comment. The sequence number is used to identify each line of G-code and is typically preceded by an asterisk (*). The address letter is used to identify the type of action the G-code is telling the CNC machine to perform. The function letter is used to tell the machine what specific action to take.

The value is a number or a set of coordinates that provides extra information about the action. Finally, the comment is an optional field that can be used to provide notes or extra information about the action. To read G-code, first look at the address letter and function letter to determine what action the line of code is telling the machine to perform. Then, look at the value to see if any additional information is provided. Finally, look at the comment to see if there are any notes or extra information included. G-code is an invaluable tool for CNC programming, and understanding its syntax is essential for creating successful CNC programs. With this beginner’s guide, you should now have a basic understanding of G-code and how to read it.

An Overview of CNC Programming Languages

Computer numerical control (CNC) programming languages are used to create instructions that control machine tools. These instructions are written in a language that the CNC machine can understand, and they tell the machine how to move, what cutting tools to use, and how to perform the machining operations. CNC programming languages allow for precise control over the cutting process, and they are essential for creating complex parts and components. The most common CNC programming language is G-code, which is a numerical control (NC) language. G-code is a standard, numerical language that is used to control the motion of machines that use the NC programming language. It is used to instruct a CNC machine on how to move and operate. G-code is the most widely used CNC programming language, and it is the language of choice for many CNC applications. Another popular CNC programming language is APT (Automatic Programming Tool).

APT is a language that is used to create instructions for CNC machines. It is based on the principles of G-code, but it has additional features that make it more powerful. APT is used to create instructions for CNC machines that are more complex than those that are written in G-code. The last CNC programming language that is commonly used is CAM (Computer Aided Manufacturing). CAM is a computer program that is used to generate instructions for CNC machines. It is used to create instructions for complex parts and components. CAM is a powerful language that is used to create instructions for CNC machines that are more complex than those that are written in G-code. CNC programming languages are essential for the successful operation of CNC machines. They allow for precise control over the cutting process, and they are essential for creating complex parts and components. CNC programming languages are used by many industries, and they are essential for the successful operation of CNC machines.

Common CNC Machining Terms and Definitions

CNC Machining is a process used in the manufacturing sector to control a machine that performs tasks such as cutting and drilling on materials. It involves the use of computer numerical control (CNC) technology to control machine tools, such as drills, lathes, routers, and mills, for the purpose of producing precision parts. The CNC technology has revolutionized the way parts are made, making it easier and faster to produce high-quality parts with great accuracy. Feed Rate: The speed at which the cutting tool moves across the work piece. It is usually measured in inches per minute (IPM). Tool Offset: This is the distance from the cutting tool to the center of the work piece. It is used to set the cutting depth of the tool. Spindle speed: This is the speed at which the spindle of the machine rotates. It is measured in revolutions per minute (RPM).

Tool Path: This is the path that the cutting tool follows as it moves across the work piece. It is programmed into the CNC machine before the machining process begins. Cutting Depth: This is the depth of the cut that the tool will make. It is usually measured in thousandths of an inch (thou). Axis of Movement: This is the direction in which the machine moves its cutting tool. It can be programmed to move in three different directions: X, Y, and Z. Tolerance: This is the allowable deviation in size or shape from the desired part design. It is typically measured in thousandths of an inch (thou). Rapid Move: This is the fastest speed at which the machine can move its cutting tool. It is usually measured in inches per minute (IPM). Lead In/Lead Out: This is the way the cutting tool is programmed to enter and exit the cut. It is used to ensure a smooth transition between cuts. Coolant: This is a fluid, usually water-based, used to lubricate and cool the cutting tool during machining. It is also used to improve the finish of the part.

The Benefits of CNC Machining Over Manual Machining

CNC machining is a manufacturing process that is becoming increasingly popular in a variety of industries due to its ability to produce high-precision products in a shorter timeframe than manual machining. This process uses computer numerical control to program a machine to cut or shape a material to the desired specifications. The advantages of CNC machining over manual machining are numerous. The most notable benefit is the increased accuracy that CNC machining provides. CNC machines are programmed with exact coordinates that the cutting tool must follow, meaning that there is no room for human error. This eliminates issues such as misalignment and incorrect cutting angles.

Additionally, CNC machines are able to produce parts with much tighter tolerances than manual machining, meaning that the parts produced are of a much higher quality. CNC machining is also much faster than manual machining. CNC machines are able to cut and shape parts with greater speed and precision than manual machines. This means that a single product can be completed in a shorter amount of time, allowing for greater productivity. CNC machining is also more cost-effective than manual machining. Since CNC machines are programmed with exact coordinates, they are able to produce parts with greater precision and accuracy in a shorter amount of time. This means that fewer materials are wasted, and fewer man-hours are required, leading to a lower cost of production.

Overall, CNC machining offers significant advantages over manual machining, and is becoming increasingly popular in a variety of industries. Its ability to produce high-precision parts with greater speed and accuracy, as well as its cost-effectiveness, make it an attractive option for manufacturers.