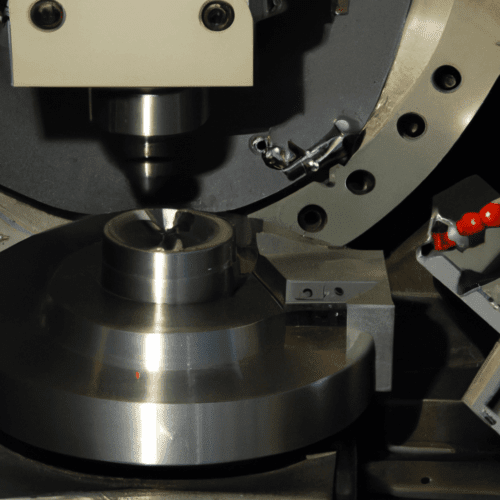

Turning is a machining process used to create a variety of parts and components. It involves a rotating workpiece, usually a cylindrical metal object, and a cutting tool that is pressed against it. The cutting tool moves in a linear direction along the workpiece, removing material in the form of chips. This process creates a variety of shapes and features, depending on the shape of the cutting tool. Turning is used to produce a variety of objects, from precision parts for medical devices to large aircraft components. It is also used to create custom metal parts, such as those used in the automotive industry.

The Rise of Used Turning for Automation & Robotics

The use of turning for automation and robotics is on the rise, and it is playing an increasingly important role in the industrial sector. Turning is a machining process in which a cutting tool is used to shape and form materials such as metals, plastics, and composites. It is used in a variety of industries, including aerospace, automotive, medical, and electronics. The rise in the use of turning for automation and robotics is largely due to the increased need for precision and efficiency in the manufacturing process. Automated turning machines are capable of producing parts with exacting precision and accuracy. This can result in improved product quality and reduced costs. In addition, automated turning machines are much faster than manual machines, resulting in shorter production times and increased efficiency. Furthermore, these machines are more reliable and require less maintenance, making them ideal for production environments.

Robotic turning machines are also becoming more popular due to their ability to quickly and accurately produce complex parts. These machines are capable of performing complex tasks such as drilling, milling, and reaming. They are also capable of performing multiple operations in a single cycle. This reduces the number of steps required to complete a job and increases efficiency. Furthermore, robotic turning machines can reduce the risk of human error and can be programmed to operate in hazardous environments. The use of turning for automation and robotics is advantageous in many ways. It can reduce costs, improve product quality, and increase efficiency. It can also reduce the risk of human error and increase safety in production environments. As the demand for precision, speed, and efficiency continues to rise, the use of turning for automation and robotics will continue to increase.

How Turning is Improving the Efficiency of Modern Manufacturing

Turning is an essential part of modern manufacturing that has significantly improved the efficiency of production processes. This advanced machining process involves the use of a rotating cutting tool to shape a workpiece by removing material from it. Turning can be used to create components from a variety of materials such as steel, aluminum, and plastic. One of the key advantages of turning is its ability to produce components with high accuracy and repeatability. As the cutting tools are guided along precise paths, they are able to produce components with a high degree of dimensional accuracy and surface finish. This precision helps manufacturers create components with precise dimensions and tight tolerances, resulting in improved product quality. Additionally, the accuracy of the machining process also reduces the amount of time and effort required for post-processing operations. Another advantage of turning is its ability to reduce production costs. By utilizing advanced CNC machines, the cutting process can be automated with minimal operator intervention.

This reduces labor costs and increases production throughput, helping manufacturers reduce production costs. Furthermore, the use of modern cutting tools and tool coatings helps reduce tool wear and prolong tool life, resulting in lower tooling costs. The use of turning also enables manufacturers to produce complex components with high levels of detail. By using advanced CNC machines, complex parts can be machined with intricate geometries such as slots, grooves, threads, and chamfers. This helps manufacturers produce components with precise details that would otherwise be difficult or impossible to achieve with other machining processes. Overall, turning has proven to be an invaluable tool for modern manufacturing, helping manufacturers reduce costs and improve production efficiency. By combining accuracy, repeatability, and cost-effectiveness, turning has become a crucial part of the modern manufacturing process.

The Benefits of Used Turning for CNC Machining

CNC machining is an important part of manufacturing, and it is important to use the best tools and techniques available to optimize the process. One such technique is using used turning for CNC machining. Used turning involves taking a pre-owned component and using it in a machining process. This technique has several benefits that make it an attractive option for CNC machining. The first benefit of using used turning for CNC machining is cost savings. Used turning components are often cheaper than new components. This can make a huge difference in the cost of a project, especially for large-scale projects. Additionally, used turning components are often easier to find than new components, which can help reduce the time needed to complete a project. Another benefit of using used turning for CNC machining is improved accuracy. Used turning components often have fewer defects than new components. This means that the results of the machining process will be more accurate and precise. This is important in many industries where accuracy is critical, such as aerospace and automotive manufacturing.

Finally, using used turning for CNC machining can help reduce the environmental impact of a project. Because the parts are pre-owned, they are being reused instead of being thrown away. This reduces the amount of waste and pollution associated with a project, which can be beneficial to both the environment and the bottom line. Overall, using used turning for CNC machining can be a great choice for many different types of projects. It can save money, improve accuracy, and reduce the environmental impact of the project. For these reasons, used turning should be considered an important part of any CNC machining project.

Used Turning vs New Turning: The Pros and Cons

Turning is a process of manufacturing that involves cutting a material to create a desired shape or size. Turning can be done either with new or used tools and equipment, and each has its own set of pros and cons. In this article, we will discuss the advantages and disadvantages of using new and used turning tools and equipment. New Turning One of the major advantages of using new turning tools and equipment is that they are usually of a higher quality than used ones. This means that they will usually last longer, making them a more cost-effective option in the long run. New turning tools and equipment will also come with a warranty, so if something goes wrong you can get it replaced or repaired. The downside to using new turning tools and equipment is that they can be more expensive than used ones. Additionally, new turning tools and equipment may require additional training and setup time before they can be used properly. Used Turning One of the main advantages of using used turning tools and equipment is that they can be much more affordable than new ones. This makes them an attractive option for people who don’t have a large budget.

Additionally, used turning tools and equipment may have already been tested and found to be reliable and effective. The downside to using used turning tools and equipment is that they may not be as reliable or of as high a quality as new ones. Additionally, they may not come with a warranty, meaning that if something goes wrong you may not be able to get it fixed or replaced. Overall, the decision to use new or used turning tools and equipment will depend on your budget, the quality of the tools and equipment available, and the reliability of the used tools and equipment. It is important to weigh the pros and cons carefully before making a decision.

Exploring the Potential of Used Turning for 3D Printing

The potential of used turning for 3D printing is an emerging area of interest among the 3D printing community. As a relatively low-cost option for producing 3D printed objects and prototypes, used turning offers a number of advantages, including increased accuracy, faster production times, and improved surface finishes. When it comes to accuracy, used turning has been shown to provide a higher level of accuracy than most traditional 3D printing methods. This is because used turning machines can be calibrated to precisely repeat the same movements, allowing for highly accurate results that are not achievable with traditional 3D printing methods. Additionally, the use of a guide rail and other precision components in used turning machines allows for improved accuracy in the production of complex shapes and features. In terms of production times, used turning can be a much faster option than traditional 3D printing. With used turning, the entire process can be completed in a matter of minutes, whereas traditional 3D printing can take hours or even days depending on the complexity of the object being produced.

This makes used turning an attractive option for those who need to produce objects quickly and efficiently. Finally, used turning can also provide improved surface finishes for 3D printed objects. Used turning machines are designed to produce smooth, uniform surfaces on 3D printed objects, which can be difficult to achieve with traditional 3D printing methods. This makes used turning an attractive option for those who are looking for a high-quality finish on their 3D printed objects. Overall, used turning offers a number of advantages for 3D printing, including increased accuracy, faster production times, and improved surface finishes. As such, it is an increasingly popular option among the 3D printing community, and one that should be explored further.