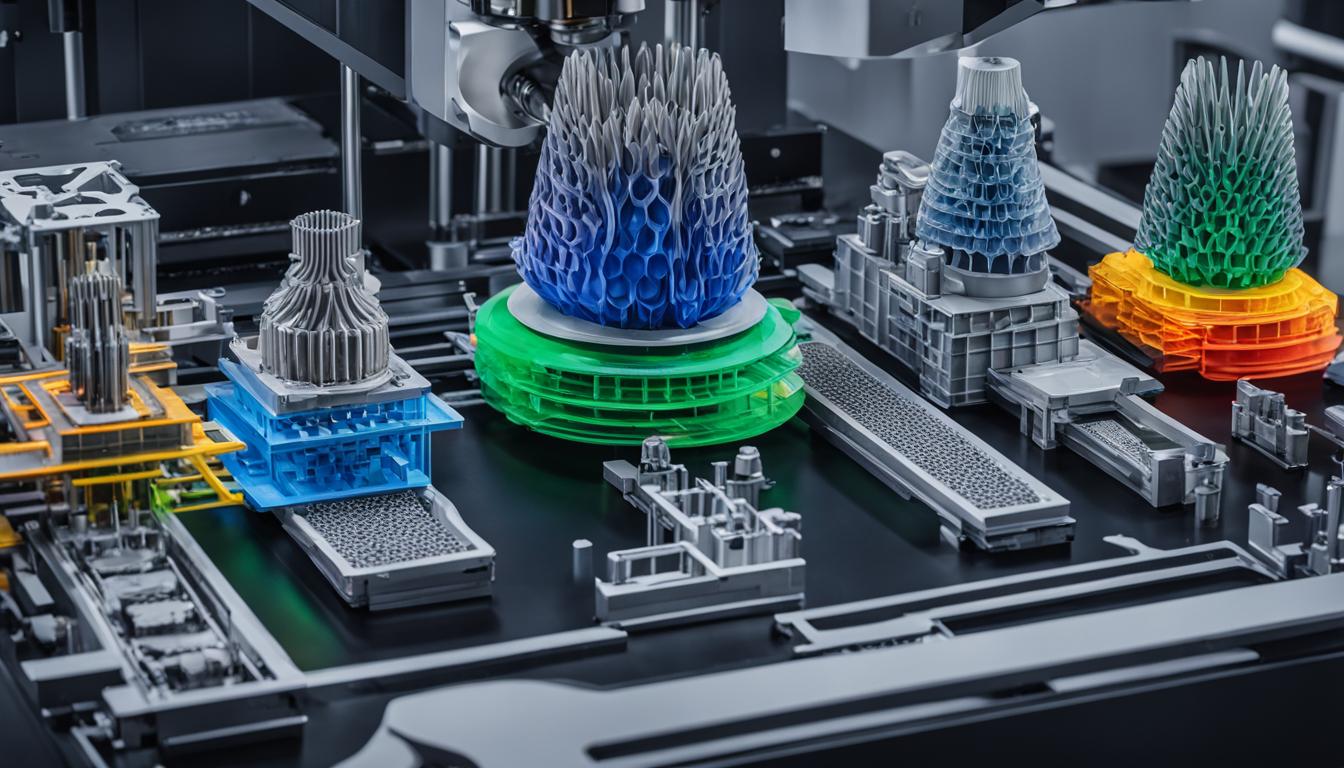

Welcome to our exploration of 3D Systems Corp., a leading company in the field of additive manufacturing and rapid prototyping. With a commitment to innovation and a customer-centric approach, 3D Systems has revolutionized product development and manufacturing processes. In this article, we will delve into their comprehensive solutions, recent news, and success stories from satisfied customers.

3D Systems is known for its expertise in accelerating time-to-market, unleashing design innovation, and optimizing costs through their advanced additive manufacturing technologies. Their solutions are used across industries such as aerospace, automotive, healthcare, and entertainment, making them a trusted partner for businesses worldwide.

Revolutionizing Product Development and Manufacturing

3D Systems specializes in providing cutting-edge 3D printing solutions that revolutionize product development and manufacturing processes. With their advanced technologies and services, they cater to various industries including aerospace, automotive, healthcare, and entertainment. Their range of professional-grade 3D printers and software empower businesses to create product concept models, prototypes, master patterns, and production parts. Leveraging their expertise in industrial 3D printing, 3D Systems enables faster time-to-market, increased design innovation, and cost optimization.

Industrial 3D printing has emerged as a game-changer in the manufacturing landscape. It offers unparalleled capabilities, transforming traditional production methods and unlocking new opportunities. By leveraging 3D printing solutions, businesses can streamline the product development cycle, reduce time and cost associated with tooling, and iterate designs more efficiently. Furthermore, it opens doors for customization, enabling the production of complex geometries and intricate structures that were previously impossible or impractical to manufacture.

3D Systems provides a comprehensive suite of tools for industrial 3D printing. Their portfolio includes a wide range of printers capable of handling various materials, from plastics to metals. Additionally, they offer software solutions that facilitate seamless design optimization, file preparation, and print management. This integrated approach ensures that businesses can harness the full potential of 3D printing technology, from conceptualization to production.

| Key Benefits of 3D Systems’ Industrial 3D Printing Solutions |

|---|

| Shortened time-to-market |

| Enhanced design flexibility and innovation |

| Cost optimization through reduced tooling and materials waste |

| Improved product quality and performance through iterative prototyping |

| Increased customization possibilities |

Unlocking New Opportunities in Manufacturing

Industrial 3D printing empowers manufacturers to push the boundaries of what is possible. With 3D Systems’ solutions, businesses can explore innovative design concepts, create intricate and lightweight structures, and optimize production processes. Whether it’s producing aircraft components with complex geometries, medical implants customized for individual patients, or lightweight automotive parts, industrial 3D printing opens up a world of possibilities.

Furthermore, additive manufacturing techniques offered by 3D Systems enable material savings and waste reduction, contributing to sustainability efforts. By using only the necessary materials to build a component, manufacturers can eliminate excess waste typically associated with traditional manufacturing methods, reducing their environmental impact.

With an extensive network of experts and industry partners, 3D Systems provides comprehensive support to businesses seeking to adopt industrial 3D printing. From initial consultation to implementation and training, their team ensures a seamless transition to this transformative technology.

The Company and its History

3D Systems Corporation, founded in 1986 by Chuck Hull, is a leading player in the 3D printing industry. With its headquarters in Rock Hill, South Carolina, the company operates on a global scale. It specializes in the design, manufacturing, and sale of 3D printers, materials, scanners, and also provides printing services. 3D Systems has been at the forefront of innovation in the field, pioneering technologies such as stereolithography (SLA) and the STL file format. The company’s remarkable growth has been fueled by strategic acquisitions, allowing it to offer a diverse range of products and services tailored to industries including aerospace, automotive, healthcare, and consumer goods.

Chuck Hull, a visionary inventor, made a significant contribution to the world of rapid prototyping by inventing stereolithography. Today, stereolithography enjoys widespread adoption and is recognized as a foundational technology in the 3D printing industry. Thanks to Chuck Hull’s revolutionary invention, 3D printing has transformed the way products are designed, prototyped, and manufactured across various sectors. As the founding father of 3D Systems and the pioneer behind stereolithography, Chuck Hull’s legacy continues to shape the future of additive manufacturing.

To gain a deeper understanding of 3D Systems and its impact on the industry, let’s take a closer look at the company’s historical timeline and key milestones.

Timeline of 3D Systems Corporation

| Year | Event |

|---|---|

| 1986 | 3D Systems Corporation is founded by Chuck Hull. |

| 1987 | Introduction of the Stereolithography (SLA) 3D printing technology. |

| 1988 | 3D Systems becomes the first 3D printing company to go public. |

| 1992 | Launch of the SLA-250, the world’s first commercially available 3D printer. |

| 1996 | 3D Systems introduces the Selective Laser Sintering (SLS) technology. |

| 2000 | Introduction of the ProJet line of 3D printers. |

| 2001 | 3D Systems develops the STL file format, which becomes the de facto standard in the 3D printing industry. |

| 2011 | Launch of the ProJet 3500 series, bringing high-definition 3D printing to a wide range of applications. |

| 2014 | 3D Systems introduces the ProX line of direct metal 3D printers. |

| 2019 | Introduction of the Figure 4® platform, revolutionizing digital manufacturing. |

With a rich history of groundbreaking innovations, 3D Systems continues to drive the advancement of additive manufacturing technologies and solutions. Through a combination of expertise, creativity, and customer-centricity, the company remains at the forefront of the rapidly evolving 3D printing industry.

Technology and Products

3D Systems offers a wide range of 3D printing technologies and products, making them a leader in the industry. Their lineup includes stereolithography (SLA), selective laser sintering (SLS), fused deposition modeling (FDM), color-jet printing (CJP), multi-jet printing (MJP), and direct metal printing (DMP). Each technology has its own unique features and applications, allowing for versatile and customizable printing solutions.

Alongside their impressive range of printers, 3D Systems also provides a comprehensive suite of content creation software for design and modeling purposes. Their software enables users to unleash their creativity, enhancing the design process and creating intricate models with ease.

To complement their cutting-edge technology, 3D Systems offers a broad range of materials for printing. From metals and composites to plastics, their extensive material library enables users to choose the most suitable materials for their specific applications. These high-quality materials ensure the production of durable and precise prints.

With a closed-source approach to technology development, 3D Systems has successfully obtained numerous patents that protect their innovative solutions. This dedication to research and development sets them apart in the industry, allowing them to continually push the boundaries of 3D printing technology.

By combining their advanced printers, software, and materials, 3D Systems offers a comprehensive solution for additive manufacturing needs across various industries. Whether it’s rapid prototyping, tooling, or production parts, their technology and products ensure efficient and high-quality results.

Success Stories and Customer Resources

3D Systems takes pride in sharing success stories from satisfied customers who have experienced the benefits of their cutting-edge 3D printing solutions. These compelling stories encompass a wide range of industries, including healthcare, automotive, and consumer products. They serve as powerful examples of how 3D printing technology has revolutionized product development and manufacturing processes.

Moreover, 3D Systems provides invaluable resources for both customers and enthusiasts, enabling them to delve deeper into the world of 3D printing. One such resource is their series of informative webinars. These webinars cover a diverse range of topics, including customer applications, innovative solutions, and detailed product insights. Attendees gain knowledge and inspiration to further optimize their creative and manufacturing processes using 3D Systems’ technologies.

In addition to webinars, 3D Systems offers a comprehensive Buyer’s Guide for 3D printing. This guide is an indispensable resource for anyone considering the implementation of 3D printing technology in their projects or businesses. It provides valuable insights into the various 3D printing technologies available and offers guidance on selecting the most suitable technology for specific needs.

Careers at 3D Systems

3D Systems offers exciting career opportunities for individuals interested in the additive manufacturing industry. As a leading partner in providing innovative solutions and pushing the boundaries of 3D printing technology, 3D Systems is at the forefront of revolutionizing product development and manufacturing processes.

When you join the 3D Systems team, you become part of a company that values expertise, fosters professional growth, and encourages innovation. With a global presence and offices around the world, 3D Systems provides ample opportunities for career development within a dynamic and fast-paced industry.

Discover a world of possibilities and shape the future of additive manufacturing with 3D Systems. Whether you’re interested in engineering, design, sales, customer support, or research and development, there’s a role for you at 3D Systems.

Join the team that is revolutionizing industries through additive manufacturing and be part of a company that is dedicated to creating cutting-edge solutions.

Benefits of Joining 3D Systems

- Competitive salary and benefits package

- Opportunities for professional growth and career advancement

- Access to state-of-the-art technology and resources

- Collaborative and innovative work environment

- Global exposure and opportunities for international travel

Start your journey in additive manufacturing and explore the exciting career opportunities at 3D Systems. Join a team that pioneers industry advancements, drives innovation, and shapes the future of manufacturing.

| Position | Location | Description |

|---|---|---|

| 3D Printing Engineer | Rock Hill, SC | Design and optimize 3D printing processes, troubleshoot technical issues, and provide expert support to customers. |

| Product Designer | San Francisco, CA | Create innovative designs using 3D modeling software, collaborate with cross-functional teams, and bring ideas to life. |

| Sales Executive | New York, NY | Identify and develop new business opportunities, build relationships with clients, and provide solutions to meet their needs. |

| Research Scientist | London, UK | Conduct cutting-edge research in additive manufacturing, develop new technologies, and contribute to industry publications. |

| Customer Support Specialist | Tokyo, Japan | Provide technical support to customers, troubleshoot issues, and ensure customer satisfaction. |

Conclusion

3D Systems, a pioneer in the field of additive manufacturing, has made significant contributions to the development and advancement of 3D printing technology. With their comprehensive solutions, customer-centric approach, and commitment to innovation, they have emerged as a leader in the industry.

By offering a diverse range of technologies, products, and services, 3D Systems is revolutionizing product development and manufacturing processes across various sectors. Their expertise in additive manufacturing is driving faster time-to-market, increased design innovation, and optimized costs for their customers.

The success stories of satisfied customers are a testament to the impact of 3D Systems in the additive manufacturing space. Furthermore, their dedication to providing valuable resources, such as webinars and a 3D printing buyer’s guide, demonstrates their commitment to educating and empowering their customers.

As the future unfolds, 3D Systems is expected to continue driving innovation and shaping the future of manufacturing, pushing the boundaries of what is possible with additive manufacturing technology.