Are you interested in designing something for a CNC machine but don’t know where to start? Look no further! This step-by-step guide will walk you through the process of CNC machine design, programming, and optimization. Whether you’re a beginner or an experienced designer, these tips and tricks will help you create accurate and efficient designs for CNC machining.

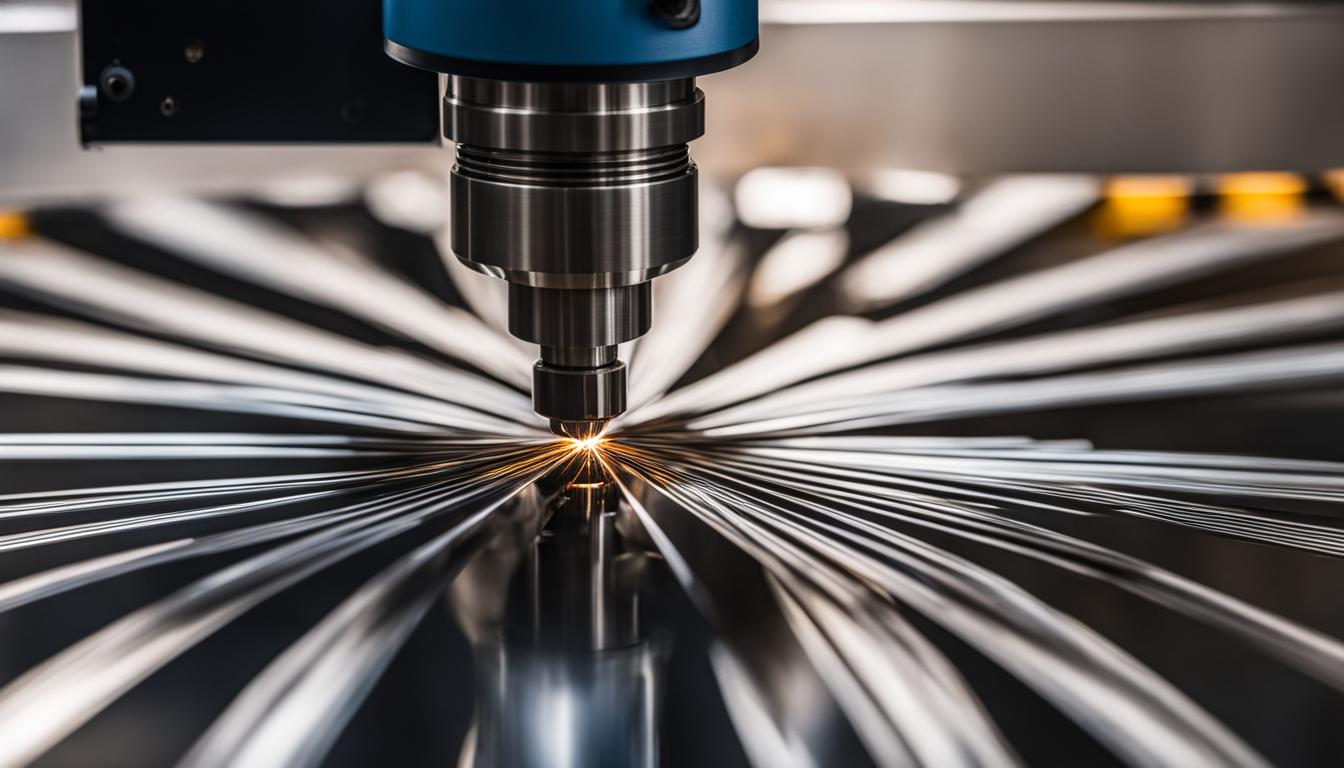

CNC machining is a subtractive manufacturing technology that involves removing material from a solid block using cutting tools. It offers high dimensional accuracy and tight tolerances, making it suitable for both high-volume production and one-off jobs. However, designing for CNC machines requires careful consideration of factors such as tool geometry, tool access, cavity depth, internal edges, thin walls, holes, small features, and part orientation.

To optimize your designs for CNC machining, you need to follow design-for-manufacturing (DFM) rules and consider the recommendations for each design parameter. By doing so, you can ensure that your designs are machinable and achieve the desired results. Whether you’re using a professional software like Fusion 360 or building your own DIY CNC machine, this guide will provide you with the knowledge and resources you need to get started.

Key Takeaways:

- Designing for CNC machines requires considering tool geometry, tool access, and design-for-manufacturing (DFM) rules.

- CNC machining offers high dimensional accuracy and tight tolerances, making it suitable for various production needs.

- Design considerations include cavity depth, internal edges, thin walls, holes, small features, and part orientation.

- Software like Fusion 360 provides a comprehensive solution for 3D modeling and CNC programming.

- Choosing and building a CNC machine should be done with careful consideration of factors such as cost, size, and capabilities.

What is CNC Machining?

CNC machining, a form of subtractive manufacturing, utilizes cutting tools to remove material from a solid block with high-speed rotation. This versatile technology is suitable for working with both metals and plastics, offering exceptional dimensional accuracy and tight tolerances. Whether it’s for high-volume production or one-off jobs, CNC machining is the go-to solution.

Unlike its additive manufacturing counterparts, such as 3D printing, CNC machining is currently considered the most cost-effective method for producing metal prototypes. The precision and repeatability of CNC machining make it ideal for industries that demand exceptional dimensional accuracy and tight tolerances.

The Advantages of CNC Machining

When it comes to high-volume production, CNC machining offers unmatched efficiency and reliability. The consistent quality of CNC machined parts ensures uniformity, making it a preferred choice for mass manufacturing. Additionally, CNC machining also caters well to one-off jobs, allowing for the creation of custom and intricate designs with ease.

The Role of Cutting Tools in CNC Machining

Cutting tools are the key components in CNC machining, shaping and forming the desired parts. These tools come in various types, including end mills, drills, reamers, and more. Their selection and configuration depend on factors such as the material being machined, the required geometry, surface finish, and overall part complexity.

Precision and Accuracy: The Hallmarks of CNC Machining

One of the core strengths of CNC machining is its ability to achieve exceptional dimensional accuracy and tight tolerances. This level of precision allows for the creation of intricate designs and intricate parts. CNC machining ensures that the machined parts meet the exact specifications and requirements, resulting in high-quality end products.

Applications of CNC Machining

CNC machining finds its applications across various industries, including automotive, aerospace, medical, electronics, and more. Its versatility and capability to work with different materials make it an indispensable manufacturing technology.

A Comparison of CNC Machining and 3D Printing

| Characteristics | CNC Machining | 3D Printing |

|---|---|---|

| Manufacturing Technology | Subtractive | Additive |

| Material Compatibility | Metal and Plastic | Wide range |

| Dimensional Accuracy | High | Moderate |

| Tight Tolerances | Yes | No |

| High-Volume Production | Yes | No |

| Customization | Yes | Yes |

Restrictions of CNC design

Despite its design flexibility, CNC machining also has certain restrictions. These limitations primarily relate to tool geometry and tool access. Common CNC cutting tools have a cylindrical shape and limited cutting length. As a result, the internal corners of CNC parts always have a radius, regardless of the cutting tool size. Additionally, features that cannot be accessed directly from above cannot be CNC machined. There are some exceptions, such as undercuts, and 5-axis CNC systems offer advanced workpiece-holding capabilities. When designing for CNC machining, it is recommended to align model features to one of the six principal directions and consider tool access for features with a large depth-to-width ratio.

Tool Geometry and Cutting Length

Common CNC cutting tools are cylindrically shaped and have a limited cutting length. This means that internal corners in CNC parts will always have a radius, regardless of the cutting tool size.

Tool Access

Features that cannot be accessed directly from above cannot be machined using CNC. However, there are exceptions such as undercuts, and 5-axis CNC systems offer greater flexibility in terms of workpiece accessibility.

Alignment and Depth-to-Width Ratio

When designing for CNC machining, it is recommended to align model features to one of the six principal directions to ensure ease of machining. Additionally, features with a large depth-to-width ratio may require more consideration for tool access.

| Design Consideration | Restriction |

|---|---|

| Tool Geometry | Internal corners always have a radius |

| Tool Access | Features not directly accessible from above cannot be machined |

| Alignment | Model features should be aligned to one of the six principal directions |

| Depth-to-Width Ratio | Features with a large depth-to-width ratio require careful consideration for tool access |

Design Considerations for Cavities and Pockets

When designing cavities and pockets for CNC machining, it is crucial to take into account the recommended cavity depth to achieve optimal results. End mill tools, commonly used in CNC machining, have a limited cutting length, typically 3-4 times their diameter. Cavities with a smaller depth-to-width ratio may encounter challenges such as tool deflection, inadequate chip evacuation, and increased vibrations. To address this, it is advisable to consider designing parts with a variable cavity depth, particularly when larger depths are required.

For deep cavities with depths exceeding six times the tool diameter, specialized tooling and extended reach tools can be utilized to ensure efficient and accurate machining.

Design Considerations for Cavities and Pockets

| CNC Design Element | Considerations |

|---|---|

| Cavity Depth | Follow recommended depth guidelines to prevent issues with tool deflection, chip evacuation, and vibrations. |

| End Mill Tools | Understand the limitations of end mills, such as their cutting length, and design cavities with appropriate depth-to-width ratios to avoid problems. |

| Tool Deflection | Avoid excessive cavity depths that may lead to tool deflection, compromising machining accuracy. |

| Chip Evacuation | Ensure adequate cavity depth to allow efficient chip evacuation during machining processes. |

| Vibrations | Design cavities with appropriate depth-to-width ratios to minimize vibrations during CNC machining. |

Design Considerations for Internal Edges

When it comes to machining internal edges in CNC parts, paying attention to design considerations is essential for achieving optimal results. Two key factors to consider are the vertical corner radius and the floor radius.

The recommended values for the vertical corner radius should be used to ensure proper machining. Increasing the corner radii slightly above the recommended value can lead to a higher quality surface finish. It is advisable to align the floor radius with the given recommendations to achieve desired outcomes.

Using the appropriate tooling for machining different floor radii is crucial. This ensures that the floor radius is accurately produced and meets the specified requirements. By selecting the right tooling, you can achieve precise and consistent results throughout the machining process.

In terms of text, engraved text is generally preferred over embossed text for CNC designs. It provides a more visually appealing and durable result. When incorporating text into your design, using the recommended font size and engraving depth is advisable to ensure legibility and optimal engraving quality.

| Design Considerations | Recommendations |

|---|---|

| Vertical Corner Radius | Follow recommended values for optimal machining |

| Floor Radius | Align with given recommendations |

| Tooling Selection | Use appropriate tooling for machining different floor radii |

| Text Design | Prefer engraved text over embossed text |

| Engraving Guidelines | Use recommended font size and engraving depth |

Design Considerations for Thin Walls

When designing thin walls for CNC machining, it is crucial to take into account the recommended minimum wall thickness. A decrease in wall thickness can result in reduced stiffness, increased vibrations during machining, and lower achievable accuracy. Therefore, maintaining an appropriate minimum wall thickness is essential to ensure the structural integrity and quality of the final product.

While the exact minimum wall thickness may vary depending on the specific part requirements, it is necessary to consider the material being used. Plastics, for example, are more prone to warping and softening during the machining process. Hence, a larger minimum wall thickness is generally recommended for plastic compared to metals to mitigate these issues.

Examining the feasible values on a case-by-case basis allows for a precise determination of the optimal wall thickness. It is crucial to strike a balance between the desired design and the limitations imposed by the material properties and manufacturing process. By carefully considering these factors, you can ensure the successful production of robust and structurally sound thin-walled components through CNC machining.

Effects of Insufficient Wall Thickness

Insufficient wall thickness can compromise the overall strength and integrity of the part. The walls may become susceptible to deformations, leading to distortions and failures in the final product. These issues can significantly impact the performance and functionality of the component.

Effects of Excessive Wall Thickness

On the other hand, excessive wall thickness can result in unnecessary material usage and increased machining time and costs. It can also lead to issues such as residual stress buildup and dimensional inaccuracies. Striking the right balance between strength, functionality, and cost-effectiveness is crucial when determining the minimum wall thickness for a CNC design.

Guidelines for Determining Minimum Wall Thickness

While each design and material have their own considerations, the following guidelines can help you determine the minimum wall thickness:

- Consult material datasheets and guidelines provided by manufacturers to understand the specific requirements for the chosen material.

- Consider the structural requirements of the part and its intended purpose. Factors such as load-bearing capacity, expected stresses, and environmental conditions can influence the minimum wall thickness necessary to ensure adequate strength and durability.

- Perform simulations and finite element analysis (FEA) to evaluate the behavior and performance of the design under different conditions. This can help identify potential weak points and determine the appropriate wall thickness to address them.

- Seek the expertise of experienced CNC machinists or design engineers who can provide valuable insights and recommendations based on their knowledge and experience.

By carefully considering the minimum wall thickness in your CNC design, you can ensure the production of high-quality parts that meet the required strength, functionality, and cost-efficiency criteria.

Design Considerations for Holes

When it comes to designing holes for CNC machining, there are several important factors to consider in order to ensure optimal results. This section will cover the selection of appropriate hole diameters, the maximum depth of holes, and the machining of threads.

Selecting the Appropriate Hole Diameter

The hole diameter is a critical aspect of hole design in CNC machining. It determines the size and fit of fasteners, as well as the overall functionality of the part. It is important to select a hole diameter that meets the requirements of the application and considers the recommended sizes for drill bits and end mill tools.

For most hole diameters larger than 1 mm, standard drill bits are suitable and readily available. However, for smaller hole diameters, it is recommended to consult the recommendations for drill bit sizes to ensure the best possible results.

Determining the Maximum Depth of Holes

The maximum depth of holes is another crucial consideration in CNC design. It is important to determine the maximum depth based on the nominal diameter of the hole. This ensures that the machining process can be completed without compromising the structural integrity of the part.

For deeper holes, specialized drill bits with extended reach capabilities are often required. These drill bits are designed to effectively remove material and maintain accuracy at greater depths.

Machining Threads in Holes

Threads are often required in CNC machined parts to facilitate the attachment of fasteners or other components. There are several methods for machining threads, including using taps and dies or CNC threading tools.

The choice of thread machining method depends on the desired thread size and length. Taps and dies are commonly used for standard thread sizes, while CNC threading tools offer greater flexibility and precision for customized thread requirements.

By carefully considering the hole diameter, maximum depth, and thread machining methods, you can ensure that your CNC machined parts meet the necessary specifications and perform effectively in their intended applications.

Design Considerations for Small Features

When it comes to CNC machining, designing small features like holes and cavities requires careful consideration. These intricate details demand specialized tools and expertise to achieve accurate machining results. Here are some essential design considerations to keep in mind:

1. Avoid Small Features If Possible

Whenever feasible, it’s advisable to avoid designing small features as they can present challenges during manufacturing. Larger features are generally easier to machine and offer better dimensional accuracy. However, if small features are necessary, it is essential to follow specific guidelines to ensure optimal machining outcomes.

2. Minimum Hole Diameter

In CNC design, using a minimum hole diameter of 2.5 mm is recommended as a guideline. This diameter ensures sufficient tool engagement and reduces the risk of tool breakage and inaccuracies. Designing holes smaller than this standard diameter requires micro-machining techniques and specialized tools.

3. Micro-Machining Challenges

Micro-machining involves working on a minuscule scale, where even slight inconsistencies can affect the part’s functionality. Achieving precision at this level requires expertise in handling the unique physics associated with cutting small features. From tool selection to tool path strategies, every aspect of micro-machining demands meticulous attention.

4. Tolerances in CNC Machining

Tolerances in CNC machining depend on various factors, including the base dimension and part geometry. Achievable tolerances can range from +-0.1 mm to +-0.02 mm, depending on the specific requirements of the project. It is crucial to communicate the desired tolerances clearly and work closely with the machining team to ensure accurate final dimensions.

| Design Consideration | Description |

|---|---|

| Avoid Small Features If Possible | Avoid designing small features as they can be challenging to machine accurately. |

| Minimum Hole Diameter | Use a minimum hole diameter of 2.5 mm as a guideline for optimal tool engagement. |

| Micro-Machining Challenges | Micro-machining requires specialized tools and expertise due to the unique challenges associated with cutting small features. |

| Tolerances in CNC Machining | Communicate the desired tolerances clearly to achieve accurate final dimensions. |

By considering these design considerations for small features, you can optimize the machining process and ensure the production of high-quality CNC machined parts.

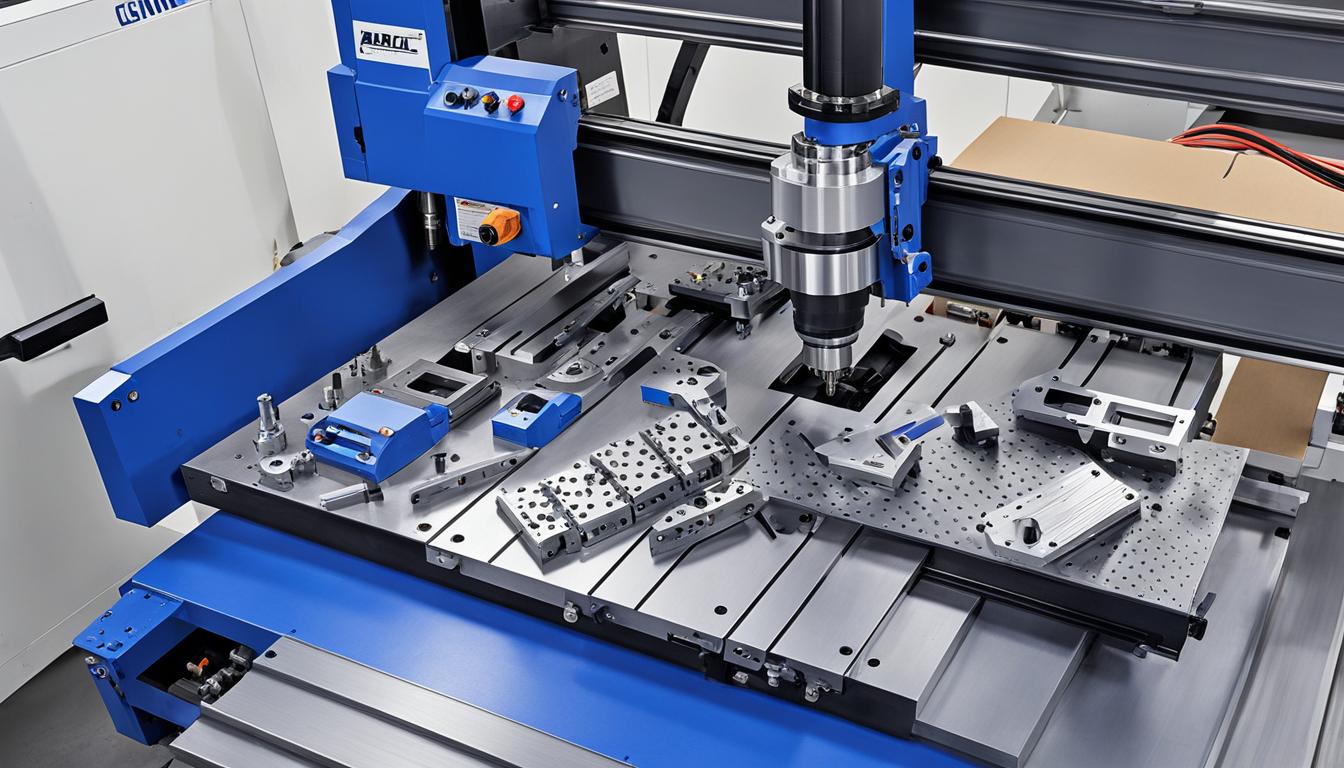

CNC Machine Setups and Part Orientation

Efficient and accurate machining in CNC requires careful consideration of machine setups and part orientation. Several factors, such as tool access, positional accuracy, and machine chatter, influence the quality and productivity of CNC machining processes.

Tool access is a critical aspect of CNC machining, as it determines the reachability of cutting tools to all surfaces of the workpiece. Sometimes, rotating the workpiece multiple times becomes necessary to ensure complete machining. However, it’s essential to keep in mind that excessive rotations can result in increased manual work and machining time.

To achieve maximum positional accuracy, it is advisable to machine multiple features in the same setup whenever possible. By minimizing the number of rotations and setups, you can reduce the potential for cumulative positional errors and improve overall machining precision.

In addition to optimizing tool access and minimizing setups, designing parts that can be machined using tools with the largest possible diameter and shortest possible length brings several benefits. Utilizing larger diameter tools enhances cutting stability, reduces deflection, and improves surface finish. Meanwhile, shorter tools minimize vibration and ensure better overall rigidity during machining.

By carefully considering CNC machine setups, part orientation, and tool access, you can enhance the efficiency, accuracy, and quality of your machining processes.

Introduction to Fusion 360

Fusion 360 is a powerful CAD software that revolutionizes 3D modeling in the CNC machining industry. With its clean and minimal user interface, Fusion 360 is designed to be beginner-friendly, allowing users to quickly learn and navigate the software.

But Fusion 360 is more than just a CAD software – it also provides a sophisticated CAM environment. This means that users can seamlessly transition from designing their 3D models to creating tool paths for CNC machining, all in one software.

Available for both Mac and PC platforms, Fusion 360 caters to a wide range of users. Whether you’re an individual hobbyist or a small business, Fusion 360 offers a free license for those making less than $100K per year, making it accessible and affordable for everyone.

With Fusion 360’s comprehensive suite of tools for computer-aided design (CAD) and its integrated computer-aided manufacturing (CAM) capabilities, users can streamline their workflow and bring their CNC machining projects to life with ease.

Getting started with Fusion 360

To begin your journey with Fusion 360, start by downloading the software from the official website and signing up for a free account. Fusion 360 offers a user-friendly interface and provides a plethora of tutorials and resources specifically designed to help beginners learn 3D modeling and CNC programming. By familiarizing yourself with the Fusion 360 interface and mastering basic navigation commands like orbit, pan, and zoom, you’ll quickly become acquainted with the software’s capabilities.

If you’re looking to add a touch of creativity to your projects, consider utilizing scripts like Image-2-Surface. This handy tool allows you to translate 2D bitmap images into stunning 3D surfaces, perfect for CNC milling.

With Fusion 360’s intuitive interface and comprehensive feature set, it’s no wonder that it’s a popular choice among designers and engineers alike. Whether you’re a beginner or a seasoned professional, Fusion 360’s powerful CAD software and CNC programming capabilities are ready to elevate your design experience to new heights.

Choosing and Building a CNC Machine

Before you decide to purchase or build a CNC machine, it is crucial to have a solid understanding of the basics of CNC machining and the key design considerations involved. CNC software can have a steep learning curve, so it is recommended to gain proficiency in computer-aided design (CAD) and computer-aided manufacturing (CAM) before investing in a machine.

When choosing a CNC machine, there are several factors to consider. First, evaluate your budget and determine the machine cost that aligns with your financial resources. Additionally, assess the size and capabilities of the CNC machine to ensure it meets your specific needs and requirements. Compatibility with the software you plan to use is also important to ensure a seamless integration between the machine and your CAD/CAM tools.

For those who enjoy taking a hands-on approach and have the necessary skills and resources, building your own DIY CNC machine is an option to consider. This not only allows for customization but also provides a deeper understanding of the machine’s inner workings. Keep in mind that building a CNC machine requires advanced technical knowledge and access to the appropriate components and tools.

Whether you choose to purchase an industrial CNC machine or embark on a DIY project, it is important to thoroughly research the available options and understand the cost, capabilities, and commitment required. By making an informed decision, you can ensure that your CNC machine is a valuable asset in bringing your ideas to life.