CNC machining difficulty is determined by several key factors that impact the complexity and precision of the manufacturing process. Material properties play a crucial role, with harder metals like titanium and Inconel requiring more specialized tooling and slower cutting speeds compared to softer materials like aluminum. Part geometry also significantly affects difficulty, as intricate designs with tight tolerances, thin walls, or deep cavities demand more advanced programming and tooling strategies.

The required surface finish and dimensional accuracy further influence complexity, with higher precision necessitating additional machining passes and more careful process control. Machine capabilities, including axis count, spindle speed, and tool changing efficiency, can either limit or enhance the ability to produce complex parts.

The expertise of the CNC programmer and operator is vital in optimizing tool paths, selecting appropriate cutting parameters, and troubleshooting issues that arise during production. Understanding these factors is essential for accurately assessing the difficulty of a CNC machining project and ensuring successful outcomes

- Understanding the level of difficulty in CNC machining is essential for manufacturers and aspiring CNC machinists.

- CNC machining requires a high level of skill and expertise to operate the machines effectively.

- Challenges in CNC machining can arise from material selection, complexity of design, batch size, machining time, tooling, tolerances, and post-machining processes.

- Strategies for mastering CNC machining include design optimization, material selection, batch size planning, machining optimization, component consolidation, regular maintenance, and supplier partnerships.

- It is crucial to balance cost and quality in CNC machining to achieve success in manufacturing projects.

What is CNC Machining?

CNC machining, short for computer numerical control machining, is a highly precise manufacturing process that utilizes advanced computer software to control the movement and operation of machines. This automation enables the production of complex parts with consistency and accuracy.

The history of CNC machining can be traced back to the early advent of automation and mechanical linkages. However, it wasn’t until the development of servomechanisms and computer systems that CNC machining truly revolutionized the manufacturing industry.

Today, CNC machining has become a cornerstone of modern manufacturing across various industries, including aerospace, automotive, electronics, and healthcare. By employing computer-controlled tools and machinery, CNC machining allows for efficient and cost-effective production of components, reducing human error and maximizing productivity.

Looking towards the future, the scope and potential of CNC machining are vast. As technology continues to advance, we can expect further improvements in automation, software integration, and precision capabilities. Additionally, the integration of artificial intelligence and machine learning into CNC machining processes holds the promise of increased efficiency and optimization.

Types of CNC Machines

There are different types of CNC machines, each designed for specific manufacturing tasks. Let’s explore the various types and their applications:

CNC Milling Machines

CNC milling machines are the most common type of CNC machines. They are used for cutting and drilling operations. These machines utilize rotary cutting tools to remove material from the workpiece. CNC milling machines are versatile and can produce complex shapes and designs with high precision.

CNC Lathes

CNC lathes are primarily used for creating components with a symmetrical structure, such as cones and cylinders. The workpiece rotates while the cutting tool moves parallel to the axis of rotation. CNC lathes are efficient in producing parts with excellent surface finishes and tight tolerances.

CNC Plasma Cutters

CNC plasma cutters use a plasma torch to cut materials, especially metal sheets. The plasma torch generates a high-velocity jet of ionized gas, which heats and melts the material. The molten material is then blown away, resulting in precise and clean cuts. CNC plasma cutters are ideal for projects that require fast cutting speeds and accurate shapes.

CNC Laser Cutters

CNC laser cutters are known for their exceptional precision and speed. These machines employ a high-powered laser beam to cut through various materials, including metal, wood, and plastics. The laser beam melts, burns, or vaporizes the material, creating intricate and detailed cuts. CNC laser cutters are widely used in industries that demand intricate designs and fine details.

Each type of CNC machine has its own capabilities and applications in the manufacturing process. The choice of CNC machine depends on the specific requirements of the project, such as the type of material, desired accuracy, and complexity of the design.

Factors Influencing CNC Machining Difficulty

Several factors influence the difficulty of CNC machining. Understanding these factors is crucial for achieving optimal results in the manufacturing process. Let’s explore the key factors that impact CNC machining difficulty:

1. Material Selection

The choice of material significantly affects the overall difficulty of CNC machining. High-performance alloys and exotic materials, such as titanium or Inconel, can pose challenges due to their hardness, heat resistance, or unique properties. Machining these materials may require specialized tooling, cutting techniques, or slower feed rates.

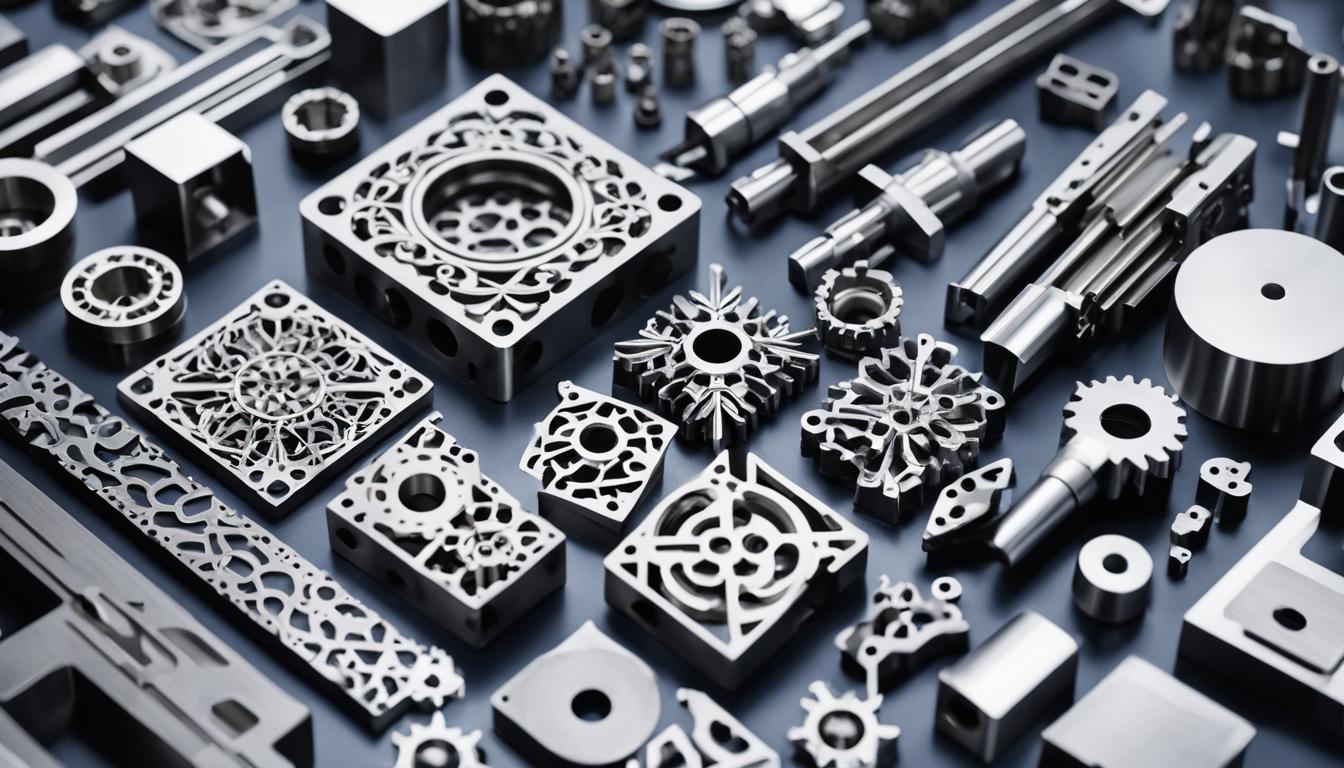

2. Complexity of Design

The complexity of the design directly correlates with the difficulty and time required for CNC machining. Intricate features, fine details, and tight tolerances add complexity to the machining process. These complex designs may necessitate advanced machining techniques, multiple setups, and meticulous attention to detail.

3. Batch Size

The batch size plays a significant role in CNC machining difficulty. Larger production runs offer economies of scale, reducing the cost per unit. However, machining larger batches may require optimization strategies, such as efficient toolpath planning and production scheduling, to maintain consistent quality and productivity.

4. Machining Time

Machining time directly influences the difficulty of CNC machining. Longer machining times can impact productivity, project timelines, and production costs. Reducing machining time requires optimization through efficient tooling selection, programming, and machining strategies.

5. Tooling and Setup

The selection of appropriate tooling and efficient setup procedures plays a crucial role in CNC machining difficulty. The choice of cutting tools, fixtures, and workholding devices impacts machining accuracy, surface quality, and overall productivity. Proper tooling selection and setup optimization can significantly enhance machining efficiency and reduce difficulties.

6. Tolerances and Surface Finish Requirements

Tight tolerances and demanding surface finish requirements can increase the difficulty of CNC machining. Meeting stringent tolerances and achieving fine surface finishes demand precision in toolpath generation, tool selection, machine calibration, and process control.

7. Post-Machining Processes

Post-machining processes, such as deburring, cleaning, heat treatment, or coating, can influence the overall complexity of CNC machining. Additional processes add time, cost, and potential challenges to the manufacturing workflow. Coordinating and optimizing post-machining processes is essential for achieving the desired final product quality.

When considering these factors, it’s crucial to collaborate with experienced CNC machining experts to navigate the challenges and optimize the manufacturing process for success.

| Factors | Influences |

|---|---|

| Material Selection | Hardness, heat resistance, unique properties |

| Complexity of Design | Intricate features, tight tolerances |

| Batch Size | Economies of scale |

| Machining Time | Productivity, project timelines, costs |

| Tooling and Setup | Machining accuracy, surface quality, productivity |

| Tolerances and Surface Finish Requirements | Precision, surface quality |

| Post-Machining Processes | Deburring, cleaning, heat treatment, coating |

Strategies for Mastering CNC Machining

Mastering CNC machining requires implementing various strategies. By following these strategies, manufacturers can optimize their processes and achieve superior results. Here are some key strategies to consider:

1. Design for Manufacturability

Collaborate with CNC machining experts during the design phase to optimize parts for the manufacturing process. By considering factors such as material selection, tolerances, and machining capabilities, you can streamline production and ensure the manufacturability of your designs.

2. Material Selection Optimization

Optimize material selection to fulfill project requirements while minimizing costs. Selecting the right materials based on their properties, availability, and affordability can have a significant impact on the overall success of your CNC machining projects.

3. Batch Size Planning

Strategically plan batch sizes to maximize economies of scale. Producing larger batches can lead to cost savings, improved efficiency, and reduced setup time. However, it’s essential to balance batch size with inventory management to avoid excess or obsolete inventory.

4. Machining Optimization

Implement machining optimization techniques such as advanced toolpaths and programming to reduce machining time and enhance efficiency. Utilize the capabilities of CNC machines to optimize tooling, feeds, speeds, and cutting trajectories for faster and more accurate machining.

5. Consolidation of Components

Consider consolidating multiple components into a single part to simplify assembly processes. By reducing the number of individual parts and improving compatibility, you can streamline production, minimize assembly time, and reduce costs.

6. Regular Maintenance

Maintain CNC machines regularly to ensure optimal performance and prevent downtime. Regular cleaning, lubrication, calibration, and inspection can prolong the lifespan of machines and minimize the risk of unexpected failures.

7. Developing Supplier Partnerships

Establish long-term partnerships with reliable suppliers to optimize cost and quality. Working closely with suppliers can lead to better collaboration, timely deliveries, cost savings through volume discounts, and access to specialized materials or technologies.

By implementing these strategies, manufacturers can enhance their CNC machining capabilities, improve efficiency, and achieve consistent quality in their manufacturing processes.

| Strategy | Description |

|---|---|

| Design for Manufacturability | Collaborate with experts to optimize parts for the manufacturing process by considering factors like material selection and tolerances. |

| Material Selection Optimization | Optimize material selection to fulfill project requirements while minimizing costs. |

| Batch Size Planning | Strategically plan batch sizes to maximize economies of scale. |

| Machining Optimization | Implement techniques to reduce machining time and enhance efficiency. |

| Consolidation of Components | Consider consolidating multiple components into a single part to simplify assembly processes. |

| Regular Maintenance | Maintain CNC machines regularly to ensure optimal performance and prevent downtime. |

| Developing Supplier Partnerships | Establish long-term partnerships with reliable suppliers to optimize cost and quality. |

Balancing Cost and Quality in CNC Machining

When it comes to CNC machining, striking the right balance between cost and quality is essential. While cost optimization is important, compromising on quality can have long-term consequences. Poorly manufactured parts can lead to operational issues and increased expenses down the line. Therefore, manufacturers need to find a harmonious equilibrium between cost and quality to ensure the success of their CNC machining projects.

Achieving cost optimization without sacrificing quality requires careful consideration and collaboration between machining experts and manufacturers. Quality assurance measures must be implemented to guarantee that the manufactured parts meet the necessary specifications. Conducting thorough inspections, using advanced metrology equipment, and rigorous testing can ensure that the desired quality standards are achieved.

Cost optimization in CNC machining can be achieved through various strategies. For instance, manufacturers can optimize production processes, reduce material waste, and implement efficient toolpaths. Consolidating components and streamlining assembly processes can also lead to cost savings. Furthermore, developing long-term partnerships with reliable suppliers can result in better pricing and collaboration, contributing to overall cost reduction.

By striking the right balance between cost and quality in CNC machining, manufacturers can achieve success in their projects. This requires careful planning, investment in quality assurance measures, and implementing cost optimization strategies. Ultimately, manufacturers who prioritize both cost and quality will be able to deliver high-quality parts while maximizing operational efficiency and profitability.