Yes, you can build your own CNC machine. CNC stands for Computer Numerical Control, and it is a type of machine that is controlled by a computer program. Building a CNC machine requires a good understanding of electronics, mechanics, and computer programming.

The first step in building a CNC machine is to decide what type of machine you want to build. There are many different types of CNC machines, such as milling machines, lathes, routers, and 3D printers. Each type of machine has its own set of components and requirements. Once you have decided on the type of machine you want to build, you will need to purchase the necessary components. This includes the frame, motors, electronics, and software.

The next step is to assemble the components. This requires a good understanding of electronics and mechanics. You will need to connect the motors to the frame, and then connect the electronics to the motors. You will also need to program the software to control the machine.

Once the machine is assembled, you will need to test it to make sure it is working properly. This includes testing the motors, electronics, and software. Once the machine is tested and working properly, you can begin using it to create your own projects.

Building a CNC machine is a complex process, but it can be done with the right knowledge and tools. It is important to research the different types of machines and components before you begin building, and to make sure you have the necessary skills and tools to complete the project.

How expensive is a CNC machine?

The cost of a CNC machine can vary greatly depending on the type of machine, its size, and the features it offers. Generally speaking, a basic CNC machine can cost anywhere from a few thousand dollars to tens of thousands of dollars. For example, a small desktop CNC milling machine can cost around $3,000, while a larger industrial CNC milling machine can cost upwards of $100,000. The cost of a CNC lathe can range from $10,000 to $100,000 or more, depending on the size and features. The cost of a CNC router can range from $2,000 to $50,000 or more, depending on the size and features. The cost of a CNC plasma cutter can range from $2,000 to $20,000 or more, depending on the size and features. The cost of a CNC laser cutter can range from $5,000 to $100,000 or more, depending on the size and features.

How much does it cost to make your own CNC machine?

The cost of making your own CNC machine will depend on the type of machine you are looking to build, the materials you will need, and the tools you will need to build it. Generally speaking, the cost of building a CNC machine can range from a few hundred dollars to several thousand dollars.

If you are looking to build a basic CNC machine, you will need to purchase a frame, motors, a controller board, and a spindle. Depending on the type of frame you choose, the cost of the frame can range from a few hundred dollars to several thousand dollars. Motors and controllers can range from a few hundred dollars to several thousand dollars, depending on the type and size of the motor and controller you choose. The spindle is the most expensive component of the CNC machine, and can range from a few hundred dollars to several thousand dollars.

In addition to the components of the CNC machine, you will also need to purchase tools and materials to build the machine. This can include things like screws, nuts, bolts, washers, and other hardware.

How much does a good CNC machine cost?

The cost of a good CNC machine can vary greatly depending on the type of machine, its size, and the features it offers. Generally speaking, a good quality CNC machine can cost anywhere from a few thousand dollars to hundreds of thousands of dollars. Smaller desktop CNC machines can cost as little as a few hundred dollars, while larger industrial CNC machines can cost upwards of $100,000 or more. The cost of a CNC machine also depends on the type of materials it is designed to work with, as well as the complexity of the parts it is designed to produce. For example, a CNC machine designed to work with aluminum or other soft metals may cost less than one designed to work with harder metals such as steel. Additionally, the cost of a CNC machine can be affected by the number of axes it has, the speed and accuracy of its movements, and the type of software it uses. Ultimately, the cost of a good CNC machine will depend on the specific needs of the user and the type of work they plan to do with it.

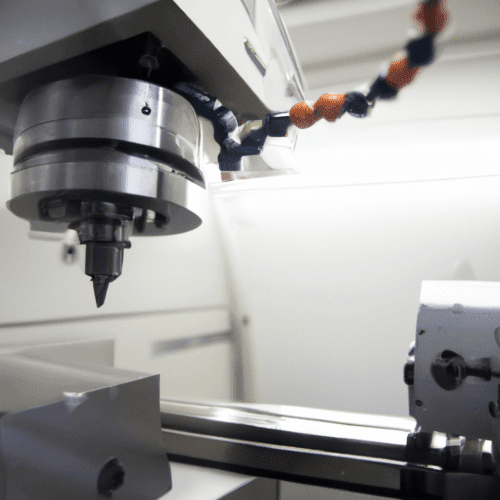

How do you make a CNC milling machine?

Making a CNC milling machine requires a great deal of skill and knowledge of the various components and processes involved. The first step is to decide what type of CNC milling machine you want to build. There are several types of CNC milling machines, including vertical, horizontal, and universal. Once you have decided on the type of machine you want to build, you will need to gather the necessary materials and tools. This includes a frame, motors, spindles, and other components.

The next step is to assemble the frame of the CNC milling machine. This involves cutting and welding the frame together, as well as attaching the motors and spindles. Once the frame is assembled, you will need to attach the motors and spindles to the frame. This is done by connecting the motors and spindles to the frame using screws and bolts.

Why are CNC machines so expensive?

CNC (Computer Numerical Control) machines are expensive because they are highly sophisticated pieces of machinery that require a significant amount of engineering and technology to produce. CNC machines are used to produce precision parts and components with a high degree of accuracy and repeatability. They are used in a variety of industries, including aerospace, automotive, medical, and electronics.

The cost of a CNC machine is determined by a number of factors, including the size and complexity of the machine, the type of materials used, and the number of features and functions it has. The cost of the machine also depends on the type of control system used, the type of software used, and the number of axes the machine has.

CNC machines are expensive because they are highly precise and require a great deal of maintenance and upkeep. They are also expensive because they require a significant amount of training and expertise to operate. The cost of the machine also includes the cost of the software and the cost of the control system.

Can you turn a 3d printer into a CNC machine?

Yes, it is possible to turn a 3D printer into a CNC machine. CNC stands for Computer Numerical Control, and it is a type of machine that uses computer-controlled motors to cut and shape materials. A 3D printer is a type of machine that uses computer-controlled motors to create three-dimensional objects from a digital file. By making a few modifications to the 3D printer, it can be used as a CNC machine.

The first step is to replace the 3D printer’s extruder with a CNC spindle. This is the part of the machine that holds the cutting tool and moves it around the material. The spindle should be compatible with the 3D printer’s motor and controller. Once the spindle is installed, the 3D printer’s software will need to be modified to control the spindle instead of the extruder.

How much does a woodworking cnc machine cost?

The cost of a woodworking CNC machine can vary greatly depending on the size and capabilities of the machine. Generally, a basic CNC machine for woodworking can cost anywhere from $2,000 to $20,000. Smaller machines, such as desktop CNC routers, can cost as little as $500, while larger industrial machines can cost upwards of $100,000. The cost of the machine will also depend on the type of CNC machine you are looking for. For example, a 3-axis CNC router will cost less than a 5-axis CNC router. Additionally, the cost of the machine will depend on the features and capabilities of the machine. For example, a machine with a larger cutting area, higher speed, and more advanced software will cost more than a machine with a smaller cutting area, lower speed, and basic software. Finally, the cost of the machine will also depend on the brand and model of the machine. Generally, higher-end machines from well-known brands will cost more than lower-end machines from lesser-known brands.

Is it cheaper to build your own CNC?

The answer to this question depends on a variety of factors, including the type of CNC machine you are looking to build, the materials and components you will need to build it, and the amount of time and effort you are willing to put into the project. Generally speaking, building your own CNC machine can be a cost-effective option if you are willing to put in the time and effort to source the necessary components and materials, and to assemble the machine yourself.

If you are looking to build a basic CNC machine, you can expect to spend anywhere from a few hundred dollars to a few thousand dollars, depending on the components and materials you choose. This cost can be significantly lower than the cost of purchasing a pre-built CNC machine, which can range from a few thousand dollars to tens of thousands of dollars.

Can you make money with CNC machine?

Yes, you can make money with a CNC machine. CNC machines are computer-controlled tools that are used to cut and shape materials such as wood, metal, and plastic. They are used in a variety of industries, including manufacturing, automotive, aerospace, and medical. CNC machines are used to create parts for products, as well as to create custom designs and prototypes.

CNC machines can be used to create a variety of products, from furniture to medical devices. They can also be used to create custom designs and prototypes for products. This means that businesses can use CNC machines to create products that are unique and customized to their needs.

CNC machines can also be used to create parts for products that are sold in stores. This means that businesses can use CNC machines to create parts for products that are sold in stores, such as furniture, automotive parts, and medical devices. This can be a great way to make money, as businesses can sell these parts to customers at a profit.

How much does a CNC cost?

The cost of a CNC (Computer Numerical Control) machine can vary greatly depending on the size, type, and features of the machine. Generally, a basic CNC machine can cost anywhere from $5,000 to $50,000, while more advanced machines can cost up to $100,000 or more. The cost of a CNC machine also depends on the type of machine you are looking for. For example, a 3-axis CNC milling machine will cost less than a 5-axis CNC milling machine. Additionally, the cost of a CNC machine can vary depending on the features and options you choose. For example, a CNC machine with a larger work area, higher speed, and more advanced features will cost more than a basic CNC machine. Additionally, the cost of a CNC machine can vary depending on the manufacturer and the type of materials used in its construction. In general, CNC machines made from higher quality materials will cost more than those made from lower quality materials.

How do you make a CNC lathe?

A CNC lathe is a computer-controlled machine tool used for machining metal parts. It is similar to a conventional lathe, but with the addition of computer numerical control (CNC) technology. CNC lathes are used to produce precision parts with complex shapes and tight tolerances.

To make a CNC lathe, you will need a CNC controller, a motor, a spindle, a tool holder, and a cutting tool. The CNC controller is the brain of the machine, and it is responsible for controlling the motion of the machine. The motor is used to drive the spindle, which is the rotating part of the machine that holds the cutting tool. The tool holder is used to hold the cutting tool in place, and the cutting tool is used to shape the material being machined.

Once all of the components are in place, the CNC controller is programmed with the desired cutting parameters. This includes the speed of the spindle, the feed rate of the cutting tool, and the depth of cut.

How can I make a milling machine at home?

Making a milling machine at home is a challenging but rewarding task. It requires a great deal of skill and knowledge, as well as access to the right tools and materials. To begin, you will need to decide what type of milling machine you want to build. There are several types of milling machines, including vertical, horizontal, and combination machines. Once you have decided on the type of machine you want to build, you will need to gather the necessary materials and tools.

The first step in building a milling machine is to create a frame. This frame will provide the foundation for the rest of the machine. You will need to decide on the size and shape of the frame, as well as the materials you will use to construct it. Common materials used for milling machine frames include steel, aluminum, and wood.