- Familiarize yourself with the technology: prior to beginning a machining project, it is important to properly educate yourself on the process and technology itself by researching online and attending seminars, if possible. Understand the basics of CNC (Computer Numerical Control), the components of the system and the processes it involves.

- Utilize optimized programming techniques: best practices when programming involve finding smart ways to reuse existing strategies and to create easy-to-use templates. Also, using graphical modeling tools can help to reduce programming time drastically.

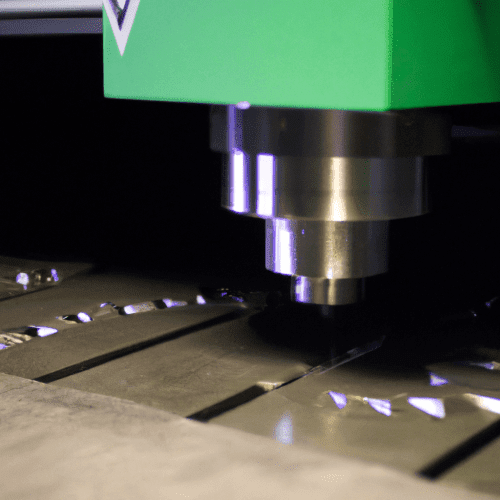

- Select the right tools and materials: depending on the project, selecting the right tools, such as the right spindle speed and feed rate, as well as the right materials, such as aluminum or steel, can help to maximize efficiency and precision.

- Ensure proper maintenance: be sure to keep the machine properly maintained for optimal performance. Regularly clean and lubricate each machine as well as all cutting tools. This will help to reduce wear and tear and ensure a smooth running every time.

- Adopt CNC automation technologies: embrace new automation technologies such as robotic material handling, which can reduce the need for manual labor and increase productivity. Automated systems can also ensure more consistent and accurate results.

- Take advantage of simulation software: make sure that simulation software is leveraged in order to reduce scrap, improve quality and optimize the tool path before machining. This can help to prevent costly mistakes, shorten part cycles and maximize efficiency.

- Constantly review and assess performance: regularly review the machine’s performance and make adjustments or upgrades as needed.

By following these steps and making the right adjustments and investments, businesses will be able to maximize their efficiency and precision when it comes to CNC technology.

How are CNC machines so precise?

CNC machines are capable of creating highly precise machined components due to their ability to convert an input design into a set of instructions for the machine to follow, which it then executes automatically with a high degree of accuracy. This is made possible through the high-precision motors and feedback systems that CNC machines use to accurately control the motion of the machine tool.

These motors are typically servo motor-based drives that use computer-controlled encoders to provide the machine with precise control over its motion axes. This type of motor has high torque and is capable of accurately moving the axis with zero mechanical backlash, and is also capable of making minute, incremental movements that enable parts to be machined to a high degree of precision.

In addition, CNC machines are able to perform tasks such as drilling and milling with accuracy that is much greater than what would be possible with manual machining. This is because the machine is controlled by exact numerical codes and algorithms which enable it to accurately repeat the same motions to a high degree of accuracy.

Finally, CNC machines are able to create highly precise machined parts due to their sophisticated feedback systems. These systems collect data about the machine’s motions such as its speed, acceleration, and position, which is then used to make corrections based on the programmed instructions. By doing so, any minor errors that may occur during machining are eliminated or corrected, resulting in highly precise parts that are accurate to within a few thousandths of an inch.

How precise are CNC machines?

CNC machines are marvels of modern engineering and have quickly become an integral part of many manufacturing processes. They offer a high degree of precision, which means that parts and components machined through CNC methods will have tight tolerances and be consistent between multiple runs.

Typically, CNC machines can produce parts and components with a precision of 0.001 inch (0.025 millimeters). When more precision is required, such as parts for the aerospace industry, the tolerances can be tightened to 0.0001 inch (0.0025 millimeters). This makes them ideal for parts where exact dimensions and tolerances are crucial. CNC machines are able to reproduce the same functions multiple times and make identical components.

Compared to other methods of machining, CNC machines are more precise as the computer automatically performs tasks as instructed by the code and not by the operator. This eliminates human error and provides repeatable results. Also, the machines are able to cut in three dimensions, which is especially useful when creating complex shapes. This is why CNC machining is used to create medical instruments, prosthetics and components used in aerospace engineering.

In conclusion, CNC machines are highly precise machines that can produce components reliably and with a level of accuracy and consistency that other methods of machining cannot match. They are able to hold tolerances up to 0.0001 inch (0.0025 millimeters) and create complex components with speed and precision. CNC machines are used in many industries and are making manufacturing more efficient and cost effective.

How motion control is achieved so precisely in CNC?

Motion control is the process that controls tool motions in the CNC (Computer Numeric Controlled) machine. It is an extremely complex system, using many different technologies and components to ensure precision.

To achieve precision, CNC machines use a number of different components, including position-sensing devices, motors, drives, and controllers. During operation, position-sensing devices such as limit switches, encoders, and resolvers detect the exact position of the tool head. This data is sent directly to the CNC controller, which interprets the information and sends signals to the motor to move the tool head to the desired position.

The motors used in CNC machines are typically either servo motors or stepper motors. Servo motors are the most precise and are generally utilized in high-end CNC machines. They receive direct signals from the CNC controller, and can hold tight accuracy without requiring any external feedback or control. Stepper motors, on the other hand, require external feedback, as they receive a sequence of pulses from the controller, and adjust the speed and position of the tool head accordingly.

The motor’s speed and acceleration can be further adjusted using the CNC machine’s drive system. This system consists of components such as increase/decrease knobs, which are used to set speeds and accelerations. The drive system also ensures that the tool head speed is maintained, regardless of any surges or spikes in power.

Finally, the CNC machine is controlled by a CNC controller. This controller processes data from the CNC machine and sends signals to motors, ensuring the accuracy and precision of the tool head’s movements. The controller is also responsible for setting the tool head’s speed and acceleration, as well as controlling feeds and speeds to maintain accuracy.

In conclusion, CNC machines are able to achieve precision by using a combination of position-sensing devices, motors, drives, and controllers. These components are used to detect the exact position of the tool head, and then send signals to the motor to adjust the tool head speed and acceleration. The drive system is then used to maintain accuracy, and the CNC controller manages the entire process.

Is CNC more precise than 3D printing?

Yes, CNC is typically more precise than 3D printing, because CNC machining is able to achieve much greater accuracy than 3D printing. CNC machining can achieve tolerances as low as 0.001 inches, whereas 3D printing can only achieve tolerances of around 0.005 inches. This means that CNC machining is more accurate and can create finer details.

In addition to accuracy, CNC machining also offers much greater control over the process of manufacturing parts. CNC can create intricate shapes and complex geometries that are not possible with 3D printing, and CNC machining can also operate at higher speeds and with greater power, allowing it to produce parts much faster and with greater strength.

However, 3D printing has some advantages over CNC machining. 3D printing is often a much faster and cheaper option if a prototype or small run is needed. 3D printing is also more accessible, and the cost of 3D printers is coming down, so the technology is becoming more widely available.

Ultimately, which technology is most suitable for any given project depends on the specific requirements, but in general, CNC is more precise than 3D printing.

What is the most precise CNC machine?

The most precise CNC machine depends on your needs. There are several CNC machines available with different accuracy levels and features. If your focus is solely on precision and accuracy, then the Hardinge Quest 42M or GSC-SL-1000HD would be the most precise, with both providing a positional accuracy of 0.00004 inches (1 μm). However, both are also very expensive and may not be necessary for your needs.

If you need a machine with a very good accuracy and a lesser price tag, then you could consider the Tormach PCNC 1100 or the Haas TM-1P. These machines are suitable for various CNC machining processes, and provide a positional accuracy of 0.0003 inches (75 μm).

In addition to these machines, there are other options on the market that provide positional accuracy in the range of 0.0006 inches (150 μm). These CNC machines are more affordable, yet still provide great accuracy that can meet your requirements.

Ultimately, the most precise CNC machine for you will depend on your specific requirements and budget. Take into account how much accuracy you need and how much you are willing to invest to find the best CNC machine for your needs.

How does a CNC machine know its position?

A CNC machine knows its position in a few ways. The most common method is by using linear encoders that measure the length of linear travel by a machine. These encoders can be connected to an application or directly to the machine itself. Additionally, rotary encoders measure the angle of rotation and can provide feedback regarding the position of the CNC machine.

The CNC machine can also be programmed with specific coordinates and be provided with a digital input. This coordinates can be programmed and stored into the controller which enables the machine know where it is located at any point in time. The CNC machine also uses a scale to provide information of the position. This scale reads of the axis movements and how far it has traveled. With this, the scale can tell the machine where it is located.

Finally, a CNC machine uses optical measuring tools that incorporate sensors such as lasers and cameras to pinpoint the start and endpoints. This is beneficial for a CNC machine because it is more accurate and can measure the position of more than just one axis.

How is CNC accuracy measured?

CNC accuracy is typically measured in terms of its repeatability, positioning accuracy, and surface finish. Repeatability measures the accuracy of operations that are repeated within a job—such as drilling holes. Positioning accuracy measures how accurately a machine can move from one location to another—such as in broaching operations. Surface finish measures how smooth and precise the final parts are. This can include smoothness of cut, accuracy of cut, surface finish of the part, and accuracy of the finish.

Repeatability accuracy is measured using a Linear Error Probable (LEP). This measures the difference between actual and desired values across a range of movements taken by the CNC machine. Generally, a LEP value of 0.0018″ or better is considered to be acceptable accuracy.

Positioning accuracy is measured through the use of a Coordinate Measuring Machine (CMM). This test evaluates a machine’s ability to accurately move to a predetermined point. Generally, positioning accuracy of 0.0001” or better is considered acceptable.

Surface finish is evaluated through the use of surface roughness testers. These instruments measure the amount of “ruff” or “smooth” on a surface to determine the surface finish. Generally, a surface finish well within the range of 8 to 20 micro-inches is considered acceptable for most operations.

Generally, the accuracy of a CNC machine is determined by evaluating its repeatability, positioning, and surface finish and determining whether or not it falls within the acceptable range of values. In some cases, machines may require more than one test to ensure that they are accurate and precise enough for their operation.