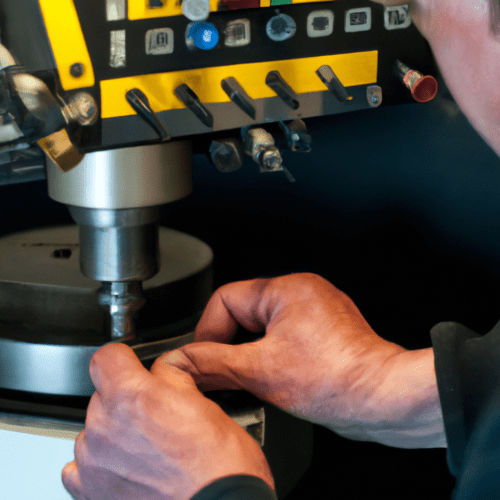

CNC (Computer Numerical Control) is a rapidly growing field that offers a wide range of career opportunities. CNC is a type of machining process that uses computer-controlled machines to cut and shape materials into precise shapes and sizes. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and manufacturing.

CNC is a great career choice for those who are interested in working with technology and machines. CNC operators are responsible for setting up and operating CNC machines, as well as programming and troubleshooting them. They must be able to read and interpret blueprints and technical drawings, as well as understand the principles of machining and tooling. CNC operators must also be able to use a variety of measuring instruments and tools, such as calipers, micrometers, and gauges.

CNC operators typically receive on-the-job training, and may also need to complete a formal apprenticeship program. Those who are interested in advancing their career may choose to pursue a certificate or degree in CNC technology.

CNC operators can expect to earn a competitive salary, with the potential to earn more as they gain experience and expertise. The job outlook for CNC operators is expected to be positive, as the demand for CNC machining is expected to increase in the coming years.

Overall, CNC is a great career choice for those who are interested in working with technology and machines. With the right training and experience, CNC operators can expect to earn a competitive salary and have a positive job outlook.

How much money does a CNC make?,How much can you make with a CNC business?

The amount of money you can make with a CNC business depends on a variety of factors, including the type of CNC machine you use, the type of work you do, the size of your business, and the amount of time and effort you put into it. Generally speaking, CNC businesses can be quite profitable, with some businesses earning up to six figures annually.

The type of CNC machine you use will have a major impact on your earnings. For example, a high-end CNC machine with advanced features and capabilities will cost more to purchase and maintain, but it will also be able to produce higher quality work and more complex projects, which can lead to higher profits. On the other hand, a basic CNC machine will be cheaper to purchase and maintain, but it will also be limited in the types of projects it can produce.

The type of work you do will also affect your earnings. If you specialize in producing custom parts or components, you can charge higher prices for your services and make more money.

Is CNC machining hard?

CNC machining is not necessarily hard, but it does require a certain level of skill and knowledge to be successful. It is a complex process that involves programming a computer to control the movement of a machine tool, such as a lathe or milling machine. The programming language used to control the machine is called G-code, and it is a language that must be learned in order to be successful. Additionally, the operator must understand the principles of machining, such as cutting speeds, feeds, and depths of cut, as well as the types of materials that can be machined.

In addition to the programming and machining knowledge, the operator must also be familiar with the machine itself. This includes understanding the safety features, the proper setup of the machine, and the maintenance that is required to keep it running properly.

Overall, CNC machining is not necessarily hard, but it does require a certain level of skill and knowledge to be successful. With the right training and experience, anyone can become a successful CNC machinist.

What state has the most CNC jobs?

The answer to the question of which state has the most CNC jobs depends on the definition of “most”. If “most” is defined as the highest number of CNC jobs, then the answer is California. According to the Bureau of Labor Statistics, California had the highest number of CNC jobs in 2019, with over 100,000 jobs. This was followed by Texas, with over 70,000 jobs, and then Michigan, with over 50,000 jobs.

However, if “most” is defined as the highest concentration of CNC jobs, then the answer is different. According to the Bureau of Labor Statistics, the state with the highest concentration of CNC jobs in 2019 was Wyoming, with 8.3 CNC jobs per 1,000 total jobs. This was followed by North Dakota, with 7.2 CNC jobs per 1,000 total jobs, and then Montana, with 6.7 CNC jobs per 1,000 total jobs.

Do CNC programmers make good money?

Yes, CNC programmers can make good money. The average salary for a CNC programmer is around $60,000 per year, depending on experience and location. CNC programmers typically work in manufacturing and engineering, and they are responsible for programming and operating CNC machines. They must be knowledgeable in computer-aided design (CAD) and computer-aided manufacturing (CAM) software, as well as the specific programming language used by the CNC machine. CNC programmers must also be able to troubleshoot and repair any issues that arise with the CNC machine.

CNC programmers typically have a high level of job security, as CNC machines are used in many industries and are essential for the production of many products. Additionally, CNC programmers can often find work in a variety of industries, such as aerospace, automotive, and medical device manufacturing.

CNC programmers can also advance their careers by taking additional courses or certifications in CNC programming. This can lead to higher salaries and more job opportunities

How long is CNC training?

The length of CNC training can vary depending on the type of CNC machine being used and the level of expertise the trainee has. For those with no prior experience, a basic CNC training course can take anywhere from a few days to a few weeks. For those with some experience, a more advanced CNC training course can take anywhere from a few weeks to a few months. For those with extensive experience, a CNC training course can take anywhere from a few months to a year or more.

The length of CNC training also depends on the type of CNC machine being used. For example, a CNC milling machine requires more training than a CNC lathe. Additionally, the complexity of the CNC machine and the type of programming language used can also affect the length of the training.

Finally, the length of CNC training also depends on the level of expertise the trainee has. For those with no prior experience, a basic CNC training course may take longer than for those with some experience.

How long does it take to learn CNC?

Learning CNC (Computer Numerical Control) can take anywhere from a few days to several months, depending on the complexity of the CNC machine and the level of expertise the learner is aiming to achieve. For someone with no prior experience, it can take a few days to learn the basics of CNC programming, such as how to write G-code and how to use the CNC machine’s control panel. However, it can take several months to become proficient in CNC programming and to be able to use the machine to its full potential.

The amount of time it takes to learn CNC also depends on the type of CNC machine being used. For example, a CNC milling machine is more complex than a CNC lathe, so it may take longer to learn how to use it. Additionally, the type of CNC programming language being used can also affect the amount of time it takes to learn CNC.

What is better laser or CNC?

The answer to the question of whether laser or CNC is better depends on the specific application. Laser technology is generally better for cutting thin materials, such as paper, fabric, and thin plastics, while CNC technology is better for cutting thicker materials, such as metals and hardwoods. Laser technology is also better for engraving and etching, while CNC technology is better for drilling and milling.

When it comes to speed, laser technology is generally faster than CNC technology. Laser technology is also more precise and can produce more intricate designs than CNC technology. However, CNC technology is more versatile and can be used to create a wider variety of shapes and sizes.

In terms of cost, laser technology is generally more expensive than CNC technology. Laser technology also requires more maintenance and is more prone to breakdowns than CNC technology.

Overall, the choice between laser and CNC technology depends on the specific application and the desired results. If speed and precision are the main considerations, then laser technology is the better choice.

How much does a hobbyist CNC machine cost?

The cost of a hobbyist CNC machine can vary greatly depending on the size and capabilities of the machine. Generally, hobbyist CNC machines are smaller than industrial machines and are designed for smaller projects. Prices for hobbyist CNC machines can range from a few hundred dollars for a basic machine to several thousand dollars for a more advanced machine. The cost of the machine will also depend on the type of materials it is made from, the size of the machine, and the features it offers.

For example, a basic hobbyist CNC machine made from plastic and aluminum may cost around $500, while a more advanced machine made from steel and aluminum may cost around $2,000. The more advanced machines may also offer features such as a larger work area, higher speed, and more precise cutting.

In addition to the cost of the machine itself, there are also other costs associated with owning a CNC machine.