What is CNC aluminum?

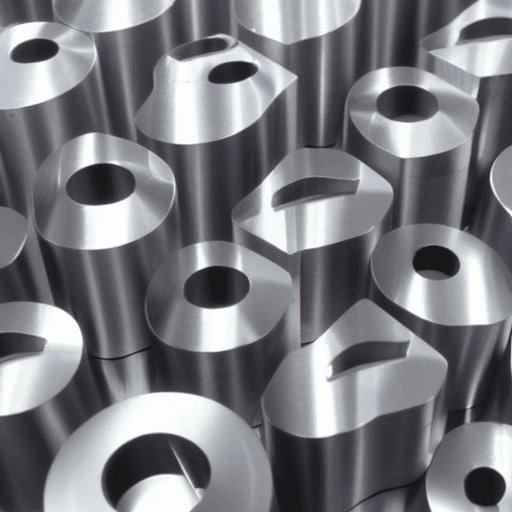

CNC aluminum is a type of metal fabrication process that uses computer numerical control (CNC) machines to shape and cut aluminum into a desired shape or design. CNC aluminum is used in a variety of industries, including aerospace, automotive, and medical, and is often used to create parts for machines, tools, and other products. CNC aluminum is a popular choice for its strength, durability, and ability to be machined into complex shapes. The process begins with a CAD drawing of the desired shape or design, which is then programmed into the CNC machine. The machine then uses a variety of cutting tools to cut the aluminum into the desired shape.

The cutting tools can range from a drill bit to a router bit, depending on the complexity of the design. Once the aluminum is cut, it is then machined to the desired specifications. This process can involve drilling, tapping, and other machining operations. Finally, the aluminum is finished with a variety of treatments, such as anodizing, powder coating, or painting. CNC aluminum is a great choice for many applications due to its strength, durability, and ability to be machined into complex shapes.

How strong is CNC aluminum?

CNC aluminum is a strong and lightweight material that is often used in the manufacturing of parts and components for a variety of industries. It is a popular choice for many applications due to its strength, durability, and corrosion resistance. CNC aluminum is also relatively easy to machine and can be formed into complex shapes.

The strength of CNC aluminum depends on the alloy used. The most common alloys used for CNC aluminum are 6061 and 7075. 6061 aluminum is a general-purpose alloy that is often used for structural applications. It has good corrosion resistance and is relatively easy to machine. It has a tensile strength of 45,000 psi and a yield strength of 40,000 psi.

7075 aluminum is a high-strength alloy that is often used for aerospace and military applications. It has excellent corrosion resistance and is relatively easy to machine. It has a tensile strength of 83,000 psi and a yield strength of 73,000 psi.

What is the full from of CNC?

CNC stands for Computer Numerical Control. It is a manufacturing process that uses computer-controlled machines to cut and shape materials such as metal, wood, and plastic. CNC machines are programmed with a set of instructions that tell the machine how to move and what to cut. The instructions are written in a computer language called G-code. CNC machines are used in a variety of industries, including aerospace, automotive, and medical device manufacturing. CNC machines are highly accurate and can produce complex shapes with a high degree of precision. They are also capable of producing parts with a high degree of repeatability, meaning that the same part can be produced multiple times with the same results. CNC machines are used in a variety of applications, including milling, drilling, routing, and engraving.

What is CNC material?

CNC material is a type of material that is used in Computer Numerical Control (CNC) machining. CNC machining is a manufacturing process that uses computer-controlled machines to shape and cut materials into a desired shape or size. CNC material is typically a metal, such as aluminum, steel, brass, or titanium, but can also be a plastic or composite material. The material is fed into the CNC machine, which then uses a variety of tools to cut, shape, and finish the material into the desired shape or size. CNC machining is used in a variety of industries, including automotive, aerospace, medical, and consumer products. CNC material is chosen based on the desired application, as different materials have different properties that make them suitable for different applications. For example, aluminum is often used for automotive parts due to its light weight and strength, while titanium is often used for aerospace parts due to its high strength and corrosion resistance.

What metals can be CNC machined?

CNC machining is a process that uses computer numerical control (CNC) machines to shape a variety of materials into a desired shape or form. CNC machining is used to create parts for a wide range of industries, including aerospace, automotive, medical, and industrial. The materials that can be machined using CNC machines include metals, plastics, composites, and wood.

Metals are the most commonly machined materials using CNC machines. Common metals that can be machined using CNC machines include aluminum, brass, copper, steel, stainless steel, titanium, and magnesium. Aluminum is the most commonly machined metal due to its low cost, light weight, and high strength. It is also easy to machine and can be used for a variety of applications. Brass is also a popular metal for CNC machining due to its strength and corrosion resistance. Copper is often used for electrical components due to its high electrical conductivity. Steel is a strong and durable metal that is often used for structural components.

What does CNC mean for metal?

CNC stands for Computer Numerical Control, and it is a process used in the manufacturing of metal parts. It is a type of automation that uses computer-controlled machines to cut and shape metal into the desired shape. The process involves the use of a computer program to control the movements of the machine, which is then used to cut and shape the metal. The CNC process is used in a variety of industries, including aerospace, automotive, and medical.

The CNC process is used to create parts with a high degree of accuracy and repeatability. It is also used to create complex shapes and intricate details that would be difficult to achieve with traditional machining methods. The CNC process is also used to create parts with a high degree of precision and repeatability, which is important for many industries.

The CNC process is also used to create parts with a high degree of accuracy and repeatability. This is done by using a computer program to control the movements of the machine, which is then used to cut and shape the metal.

Can you CNC plastic?

Yes, it is possible to CNC plastic. CNC stands for Computer Numerical Control, and it is a process that uses computer-controlled machines to cut and shape materials. CNC machines can be used to cut and shape a variety of materials, including plastic.

Plastic is a popular material for CNC machining because it is relatively easy to work with and is available in a wide range of colors, textures, and grades. It is also relatively inexpensive and can be machined to very precise tolerances.

When CNC machining plastic, the material is typically cut with a router, mill, or lathe. The cutting tool is usually a high-speed rotating bit that is guided by a computer-controlled system. The cutting tool is programmed to move in a specific pattern, which is determined by the design of the part being machined.

The cutting tool is usually made of carbide or diamond, and it is designed to cut through the plastic without causing too much heat or friction.

Why is Aluminium used in CNC turning?

Aluminium is a popular choice for CNC turning because of its combination of desirable properties. It is lightweight, strong, and corrosion-resistant, making it an ideal material for many applications. Additionally, aluminium is relatively easy to machine, making it a great choice for CNC turning. It is also relatively inexpensive compared to other metals, making it a cost-effective option for many projects.

Aluminium is also a good choice for CNC turning because it is a malleable metal, meaning it can be easily shaped and formed into complex shapes. This makes it ideal for creating intricate parts and components. Additionally, aluminium is a good conductor of heat, making it a great choice for applications that require heat dissipation.

Finally, aluminium is a non-magnetic material, making it a great choice for CNC turning applications that require parts to be non-magnetic. This is especially important for applications that involve sensitive electronics, as magnetic fields can interfere with their operation.

What is the best plastic to CNC?

The best plastic to CNC depends on the application and the desired outcome. Generally, the most common plastics used for CNC machining are Acetal (POM), Acrylic (PMMA), Nylon (PA), Polycarbonate (PC), Polypropylene (PP), and Polyethylene (PE).

Acetal (POM) is a strong, stiff, and dimensionally stable plastic that is resistant to many chemicals and solvents. It is often used for parts that require high strength and stiffness, such as gears, bearings, and other mechanical components.

Acrylic (PMMA) is a transparent plastic that is easy to machine and has excellent optical properties. It is often used for parts that require transparency, such as lenses and light fixtures.

Nylon (PA) is a strong and flexible plastic that is resistant to wear and abrasion. It is often used for parts that require strength and flexibility, such as gears, bearings, and other mechanical components.

What is the best Aluminium for machining?

The best aluminum for machining is the one that best suits the specific application. Generally, aluminum alloys with higher levels of silicon, copper, and magnesium are considered to be the best for machining. These alloys are known for their good machinability, strength, and corrosion resistance. Aluminum alloys with higher levels of zinc, manganese, and chromium are also good for machining, but they are not as strong or corrosion resistant as the alloys with higher levels of silicon, copper, and magnesium. Additionally, aluminum alloys with higher levels of iron and nickel are not as good for machining as the other alloys.

When selecting an aluminum alloy for machining, it is important to consider the specific application and the desired properties of the finished product. For example, if the application requires a strong and corrosion-resistant part, then an aluminum alloy with higher levels of silicon, copper, and magnesium would be the best choice.

What are the different grades of Aluminium?

Aluminium is a lightweight, corrosion-resistant metal that is used in a variety of applications, from construction to electronics. It is available in a range of grades, each with its own unique properties and characteristics. The most common grades of aluminium are:

1. 1100: This is the most commercially available grade of aluminium and is the most widely used. It is soft and ductile and has excellent corrosion resistance, making it ideal for a variety of applications.

2. 2024: This grade of aluminium is used in aircraft and aerospace applications due to its high strength-to-weight ratio. It is also used in the manufacture of high-performance components such as pistons and gears.

3. 3003: This grade of aluminium is often used in the manufacture of food and beverage containers, as it is highly resistant to corrosion and has excellent formability.

4. 5052: This grade of aluminium is often used in the manufacture of marine and automotive components due to its excellent corrosion resistance and weldability.

How does CNC work?

Computer Numerical Control (CNC) is a manufacturing process that uses computer-controlled machines to automate the production of parts and components. CNC machines are programmed with a set of instructions that tell the machine how to move and what tools to use to create a specific part or component. The instructions are typically written in a computer language called G-code, which is a numerical code that tells the machine what to do.

The CNC machine is typically composed of three main components: the controller, the machine tool, and the cutting tool. The controller is the computer that runs the CNC program and sends instructions to the machine tool. The machine tool is the physical machine that moves the cutting tool to create the part or component. The cutting tool is the tool that actually cuts the material to create the desired shape.

To begin the CNC process, the programmer will create a program that contains the instructions for the CNC machine. This program is typically written in G-code and is then loaded into the controller.

What are the disadvantages of CNC?

Computer Numerical Control (CNC) is a technology that has revolutionized the manufacturing industry, allowing for the automation of complex processes and the production of high-precision parts. However, like any technology, CNC has its drawbacks.

One of the main disadvantages of CNC is the high cost of implementation. CNC machines are expensive to purchase and maintain, and require specialized training for operators. Additionally, CNC machines require a significant amount of energy to operate, which can add to the cost of production.

Another disadvantage of CNC is that it can be difficult to troubleshoot and repair. CNC machines are complex systems, and require specialized knowledge to diagnose and repair any issues that may arise. This can lead to costly downtime and delays in production.

CNC machines are also limited in their flexibility. Once a CNC machine is programmed, it can only produce parts that are designed for that specific machine. This means that if a design needs to be changed, the entire machine must be reprogrammed, which can be time-consuming and costly.

What are the advantages of CNC machine?

CNC (Computer Numerical Control) machines are automated machines that are used to perform a variety of tasks in manufacturing and other industries. CNC machines are highly accurate and can be programmed to perform complex tasks with precision and repeatability. The advantages of CNC machines include increased productivity, improved accuracy, reduced labor costs, improved safety, and increased flexibility.

Increased productivity is one of the main advantages of CNC machines. CNC machines are able to perform complex tasks quickly and accurately, which can significantly reduce production time and increase output. CNC machines are also able to produce parts with a high degree of accuracy, which can reduce the need for rework and scrap.

Improved accuracy is another advantage of CNC machines. CNC machines are able to produce parts with a high degree of accuracy, which can reduce the need for rework and scrap. CNC machines are also able to produce parts with a high degree of repeatability, which can reduce the need for manual adjustments and rework.

What does the N in CNC stand for?

The N in CNC stands for numerical. CNC stands for Computer Numerical Control, and is a type of automation used in the manufacturing industry. It is a process in which a computer is used to control the movement of tools and machinery in order to produce a desired outcome. CNC machines are programmed with a set of instructions that tell the machine what to do and how to do it. The instructions are written in a numerical language, which is why the N in CNC stands for numerical. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

They are used to produce a wide range of products, from simple parts to complex components. CNC machines are highly accurate and can produce parts with a high degree of precision. They are also capable of producing parts with complex shapes and intricate details. CNC machines are used in many different types of manufacturing processes, including milling, drilling, turning, and grinding. CNC machines are also used in the production of 3D printed parts.

Why is aluminum easier to machine?

Aluminum is a relatively soft metal, which makes it easier to machine than harder metals such as steel. Aluminum is also more ductile than steel, meaning it can be bent and shaped more easily. Additionally, aluminum has a lower melting point than steel, which makes it easier to cut and shape with tools. Aluminum is also less likely to corrode than steel, which makes it easier to machine without worrying about rust or other corrosion issues. Finally, aluminum is a lighter metal than steel, which makes it easier to handle and manipulate when machining. All of these factors make aluminum a great choice for machining, as it is easier to work with than other metals.

Is Aluminium easier to machine?

Aluminium is generally considered to be easier to machine than other metals due to its low melting point, low density, and good thermal conductivity. Aluminium is also relatively soft and ductile, which makes it easier to cut and shape. Additionally, aluminium has a low coefficient of friction, which reduces the amount of heat generated during machining and helps to reduce tool wear. Aluminium is also relatively corrosion-resistant, which makes it easier to machine without the need for additional lubrication or protective coatings. Finally, aluminium is relatively inexpensive compared to other metals, which makes it a cost-effective choice for machining. All of these factors make aluminium an ideal choice for machining applications.

What’s the difference between 6061 and 7075 aluminum?

The main difference between 6061 and 7075 aluminum is in their respective strength and hardness. 6061 aluminum is a general-purpose aluminum alloy that is made up of silicon and magnesium. It is highly corrosion resistant and weldable, and it is heat treatable. It is also relatively lightweight and has good formability. 7075 aluminum is an alloy that is made up of zinc, magnesium, copper, and chromium. It is much harder and stronger than 6061 aluminum, but it is less formable and has lower corrosion resistance. It is also much heavier than 6061 aluminum.

6061 aluminum is often used in the manufacture of aircraft components, truck frames, and bicycle frames. It is also used in the manufacture of yachts, boats, and other marine vessels. 7075 aluminum is often used in the manufacture of high-end bicycle frames, aircraft components, and other aerospace components. It is also used in the manufacture of high-end sporting goods, such as golf clubs and tennis rackets.