CNC programming for accuracy requires meticulous attention to detail and a deep understanding of machining principles. Precision in CNC operations hinges on several key factors: accurate tool path generation, proper tool selection, optimal cutting parameters, and rigorous machine calibration. Programmers must consider material properties, tool wear, and thermal expansion to achieve tight tolerances.

Advanced techniques like cutter compensation, probing cycles, and adaptive control systems further enhance precision. Careful consideration of workpiece fixturing, coolant application, and chip evacuation also plays a crucial role in maintaining accuracy throughout the machining process. By combining these elements with thorough program verification and simulation, CNC programmers can consistently produce high-precision parts that meet or exceed stringent quality standards. Continuous improvement through post-process analysis and feedback integration ensures that CNC programming remains at the cutting edge of manufacturing accuracy.

- G-code and M-code: These programming languages control the machine’s movements and functions, allowing for precise geometric positioning and tool operations.

- CAM software: Advanced computer-aided manufacturing software, such as Mastercam, enables programmers to create and simulate toolpaths, verifying accuracy before production.

- Calibration and measurement: Regular machine calibration and the use of precision measurement tools like digital calipers, micrometers, and gauge blocks are essential for maintaining accuracy.

- Material-specific programming: Tailoring parameters to different materials ensures optimal cutting conditions and prevents damag.

- Multi-axis synchronization: Proper coordination of multiple axes is critical for executing intricate designs accurately, especially in industries like aerospace.

- Error prevention: Implementing thorough program testing, including dry runs and first article inspections, helps catch and correct potential issues before full production.

By mastering these elements, CNC programmers can achieve superior accuracy, consistently producing high-quality parts that meet exact specifications and tight tolerances. This precision is particularly vital in industries such as automotive, aerospace, and medical device manufacturing, where even minor deviations can have significant consequences.

- CNC programming focuses on achieving precision and accuracy in machining operations.

- G-code instructions drive CNC tools and machines to shape materials into desired forms.

- Understanding CNC machine mechanics is crucial for optimizing programming.

- CNC programming finds applications in various industries, including precision manufacturing, healthcare, aerospace, and automotive.

- Continuous learning is essential for staying up-to-date with evolving methodologies and advancing CNC machining expertise.

The Components of CNC Machine Mechanics

CNC machines rely on various mechanical components to ensure precise and efficient machining operations. These components work in harmony to facilitate the movement and control of the machine, resulting in accurate and high-quality output.

Machine Bed

The machine bed serves as the foundation of the CNC machine. It provides stability and absorbs vibrations caused by machining operations. The design and construction of the machine bed play a vital role in maintaining the machine’s accuracy and preventing any distortions during operation.

Spindles and Tooling

The spindles and tooling systems of a CNC machine generate the necessary rotational force and securely hold cutting tools. They enable the machine to shape and cut materials with precision. The robustness and precision of these components are crucial for achieving accurate and consistent results.

Linear Motion Systems

Linear motion systems allow CNC machines to move smoothly and precisely along multiple axes. These systems include components such as linear guides, ball screws, and servo motors. By ensuring precise movement, linear motion systems contribute to the overall accuracy and repeatability of the machining process.

Control Systems

Control systems are the brains behind CNC machines. They oversee and coordinate all mechanical operations, ensuring that the machine follows the programmed instructions accurately. Control systems interpret the G-code instructions and send signals to various components of the machine to control speed, direction, and tool selection.

Feedback Systems

Feedback systems continuously monitor and adjust the machine’s performance to maintain accuracy and quality. These systems utilize sensors to gather real-time data on factors such as position, speed, and temperature. Based on this data, the feedback systems make adjustments to compensate for any deviations or errors, ensuring consistent and precise machining.

The Process of CNC Machining

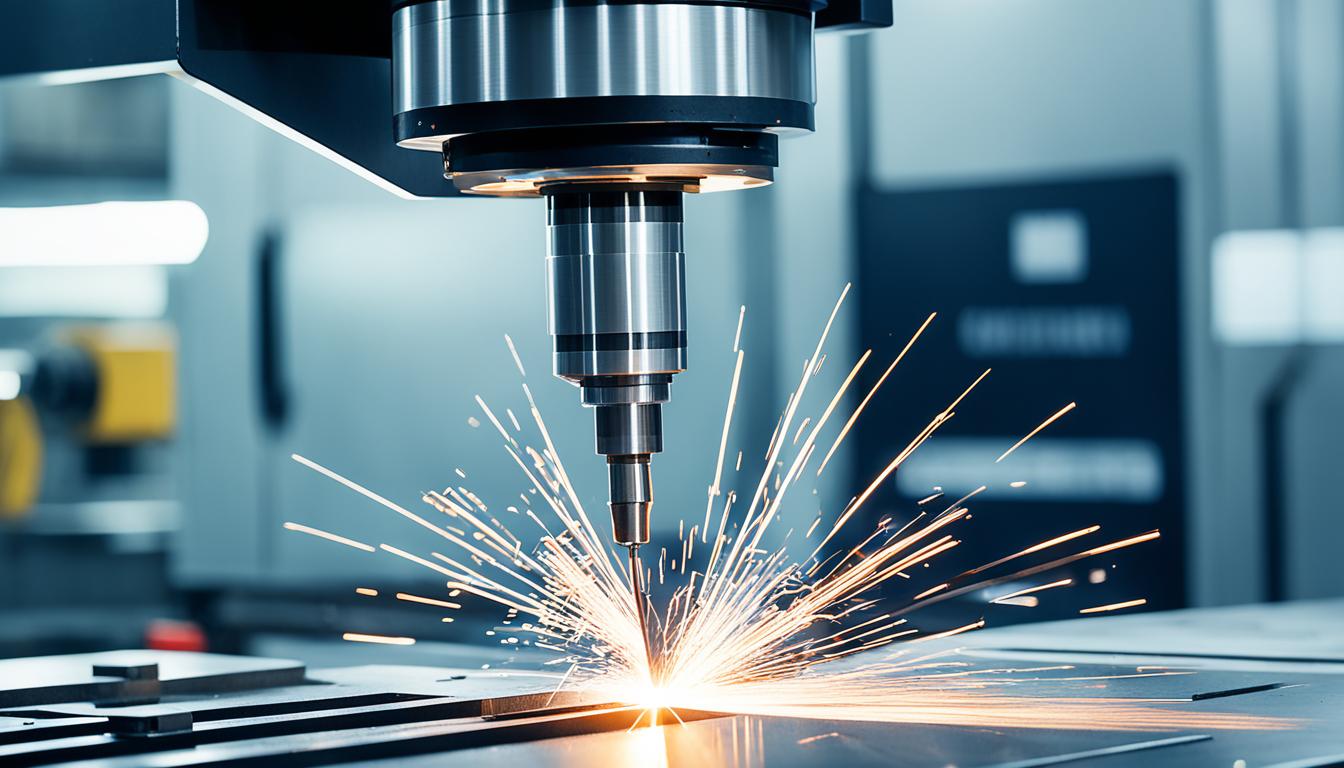

In the world of manufacturing, CNC machining has revolutionized the way parts and components are made with unrivaled precision. The process of CNC machining involves several key steps that ensure the accurate and efficient production of desired forms.

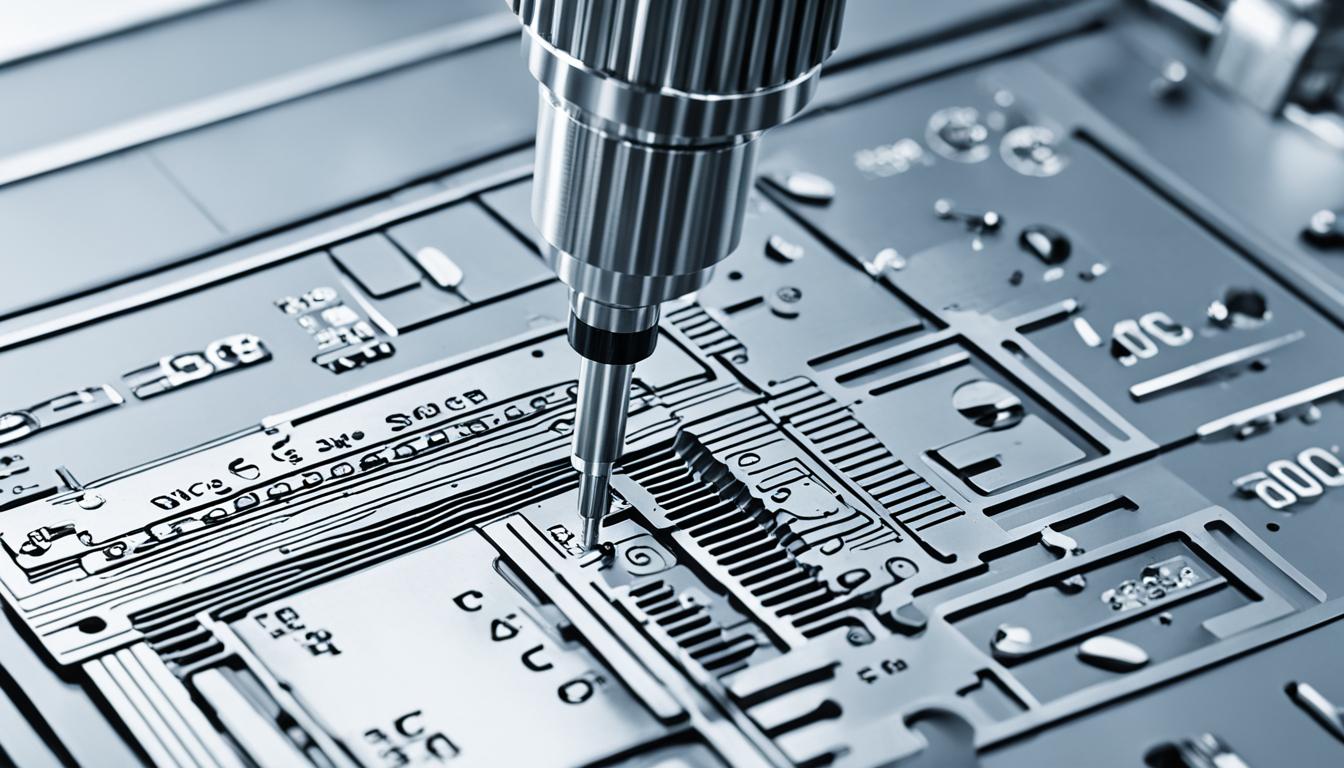

At the heart of CNC machining is the CNC programming process. Skilled CNC programmers translate designs into computer instructions known as G-code. These instructions serve as a roadmap for the CNC machine to follow, guiding its every movement and operation.

Generating Toolpaths with CAM Software

Once the G-code instructions are ready, CAM (Computer-Aided Manufacturing) software comes into play. CAM software plays a vital role in generating toolpaths. Toolpaths are the precise routes that the cutting tool will follow during machining to achieve the desired results.

The CAM software takes the design file and converts it into a set of instructions that the CNC machine can understand. These instructions dictate the order and speed at which the tool traverses the material, ensuring precise cuts and engraving.

Executing CNC Machine Instructions

With the G-code instructions and toolpaths in place, it’s time for the CNC machine to take center stage. The CNC machine follows the instructions meticulously, executing each movement with utmost accuracy.

As the machine moves, it interacts with the material, shaping it according to the programmed design. The machine may perform various operations such as cutting, drilling, milling, or engraving, depending on the complexity of the part and the instructions provided.

Monitoring and Adjusting for Optimal Results

Throughout the CNC machining process, operators closely monitor the operation, ensuring that everything goes according to plan. They keep a watchful eye on the machine’s performance, checking for any deviations or issues that may affect the quality of the final product.

Should any adjustments be necessary, operators have the skills and expertise to make real-time changes to optimize the machining process. These adjustments might involve modifying feed rates, cutting depths, or tool selection to improve efficiency and accuracy.

| Step | Description |

|---|---|

| CNC Programming | Translate design into G-code instructions |

| CAM Software | Generate toolpaths based on the design |

| CNC Machine | Execute instructions and shape the material |

| Monitoring and Adjusting | Closely monitor the process and make real-time adjustments |

The process of CNC machining, from programming to execution, is a carefully orchestrated dance between man and machine. With the right combination of technical expertise, software proficiency, and attention to detail, CNC machining delivers unparalleled precision and accuracy in the manufacturing industry.

Different Approaches to CNC Programming

CNC programming can be approached in different ways depending on the complexity of the part and the user’s expertise. Let’s explore three common methods: manual CNC programming, conversational programming, and CAD-for-CAM.

Manual CNC Programming

Manual CNC programming involves manually entering commands into the control console of the CNC machine. Skilled programmers utilize their expertise to write precise G-code instructions that control the machine’s movements and operations. This method requires in-depth knowledge of CNC machine mechanics, tooling, and programming languages. While it may be time-consuming, manual CNC programming provides complete control over the machining process and is often preferred for intricate, custom projects.

Conversational Programming

Conversational programming offers a user-friendly alternative to manual coding. With conversational programming, operators can input instructions using plain English commands or follow guided prompts on the machine’s interface. By simplifying the programming process, this method enables operators with limited programming experience to efficiently control the CNC machine. Conversational programming is suitable for less complex parts or when a quick turnaround is required.

CAD-for-CAM

For complex parts and intricate designs, CAD-for-CAM is a popular choice. CAD (Computer-Aided Design) software is used to create a 3D or CAD model of the part. This model serves as the basis for CAM (Computer-Aided Manufacturing) software, which automates the generation of toolpaths. The CAM software analyzes the part’s geometry and automatically generates the necessary G-code instructions, optimizing toolpaths for efficient machining. CAD-for-CAM provides a streamlined and highly accurate approach to CNC programming, particularly for intricate designs and multi-axis machining.

Here’s a visually engaging table summarizing the different approaches to CNC programming:

| Approach | Description |

|---|---|

| Manual CNC Programming | Entering commands into the control console manually |

| Conversational Programming | Using plain English commands or guided prompts |

| CAD-for-CAM | Automated toolpath generation based on 3D or CAD models |

Each approach has its advantages and is suitable for different scenarios. CNC programmers can choose the method that best aligns with their expertise, project requirements, and desired level of control.

Applications of CNC Programming

CNC programming is a versatile technique that finds applications across various industries. Let’s explore some of the key sectors where CNC programming plays a crucial role:

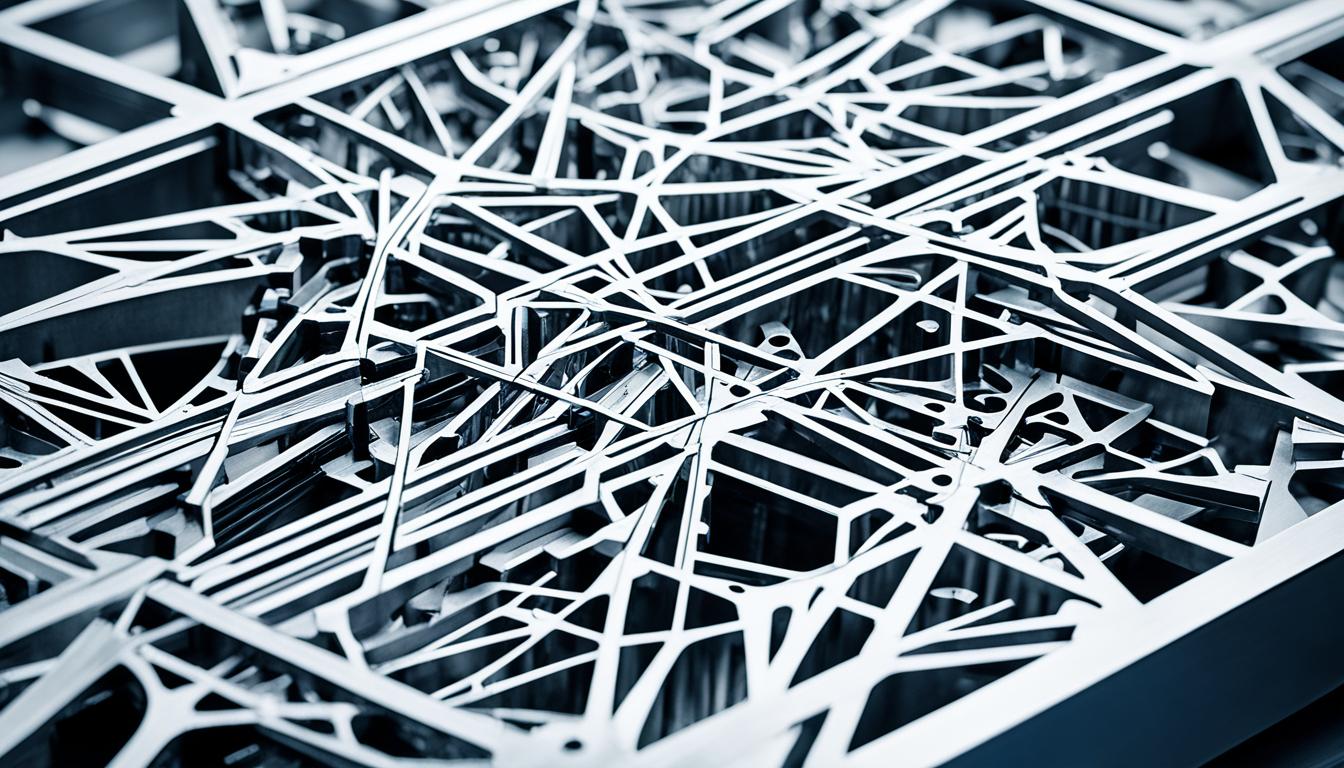

Precision Manufacturing

In precision manufacturing, CNC programming enables the production of custom prosthetics, medical device components, and intricate parts for consumer electronics. By leveraging the precision of CNC machines, manufacturers can achieve high-quality, accurate results that meet the stringent requirements of these industries.

Healthcare Industry

The healthcare industry relies on CNC programming to create custom implants and prosthetics. By utilizing advanced CNC technology, medical professionals can produce tailor-made devices that perfectly fit each patient’s unique anatomical requirements, enhancing patient comfort and improving treatment outcomes.

Aerospace

In the aerospace sector, CNC programming is essential for crafting aircraft components. Aerospace manufacturers utilize CNC machines to produce complex, high-precision parts with tight tolerances. This ensures the structural integrity and performance of aerospace components, promoting safety and efficiency in the aviation industry.

Automotive Industry

The automotive industry heavily relies on CNC programming for manufacturing engine components and intricate parts for vehicles. CNC machines are utilized to produce complex shapes and precise dimensions required for optimal engine performance and overall vehicle quality. The use of CNC programming in automotive manufacturing enables efficient production processes and consistent, high-quality automotive parts.

These are just a few examples of the diverse applications of CNC programming in various industries. The versatility and precision of CNC programming make it a valuable tool for achieving accuracy and efficiency in manufacturing processes.

| Industry | Applications |

|---|---|

| Precision Manufacturing | Custom prosthetics, medical device components, intricate parts for consumer electronics |

| Healthcare | Custom implants, prosthetics |

| Aerospace | Aircraft components |

| Automotive | Engine components, intricate parts for vehicles |

Essential Skills for CNC Programming

Mastering CNC programming requires a combination of technical proficiency, mathematical acumen, and familiarity with CAD/CAM software and measurement tools. These skills are essential for CNC programmers to navigate the intricacies of G-codes, M-codes, and T-codes, translate designs into accurate tool paths, and optimize machining processes.

To excel in CNC programming, individuals must have a strong technical foundation. This includes a deep understanding of G-codes, which are the instructions that control the CNC machine’s movements and operations. M-codes and T-codes, on the other hand, dictate additional machine functions and tool selection, respectively. Proficiency in using CAD/CAM software is also crucial, as it allows programmers to convert design concepts into precise machining instructions.

Mathematical acumen plays a vital role in CNC programming. Geometry, trigonometry, and calculus are fundamental mathematical disciplines used to calculate tool paths, angles, and complex curves. A keen understanding of these principles enables programmers to optimize tool movements and achieve accurate results. Additionally, measurement skills are essential for verifying part dimensions and maintaining quality control. Familiarity with measurement tools like calipers, micrometers, and coordinate measuring machines (CMMs) is invaluable in ensuring precision and accuracy in CNC machining processes.

Overall, CNC programming demands a combination of technical expertise, mathematical proficiency, and knowledge of CAD/CAM software and measurement tools. By honing these skills, programmers can effectively translate designs into instructions, optimize tool paths, and achieve superior accuracy in CNC machining operations.

Stay tuned for the next section, where we’ll discuss the pitfalls to avoid in CNC machining and how to optimize tool paths for enhanced efficiency and precision.

Pitfalls to Avoid in CNC Machining

While CNC machining offers numerous benefits in terms of precision and efficiency, there are certain pitfalls that manufacturers should be aware of to ensure successful operations. By avoiding these common mistakes, you can optimize your CNC machining processes and achieve superior results.

1. Overconfidence

Overconfidence can be a dangerous trait in CNC machining. When operators become too confident in their abilities, they may overlook critical details or ignore essential safety protocols. This can lead to costly errors, compromised quality, and potential safety hazards. It is crucial to maintain a cautious and attentive mindset throughout the machining process, prioritizing precision and safety at all times.

2. Ignoring Maintenance

Proper maintenance is essential for the longevity and performance of CNC machines. Neglecting routine maintenance tasks, such as regular cleaning and lubrication, can result in premature wear and tear on machine components. This not only decreases the lifespan of the machine but also affects the accuracy and quality of the machining results. To avoid these issues, establish a comprehensive maintenance schedule and adhere to it diligently.

3. Neglecting Quality Control

Quality control is a fundamental aspect of CNC machining that should never be overlooked. Ignoring quality control measures, such as statistical process control (SPC) and Six Sigma methodologies, can lead to inconsistent quality and wasted resources. Implementing robust quality control procedures ensures that every part produced meets the required specifications, minimizing defects and maximizing customer satisfaction.

By being aware of these pitfalls and taking proactive measures to mitigate them, manufacturers can optimize their CNC machining processes and achieve exceptional accuracy and quality in their final products.

Optimizing Tool Paths in CNC Programming

Efficiency and precision are paramount in CNC programming, and optimizing tool paths plays a crucial role in achieving these goals. By employing various techniques, such as minimizing time and distance traveled by the tool, waste reduction and energy consumption can be minimized. Additionally, optimizing tool paths for complex surfaces involves calculating gradients and curvatures to ensure accurate machining. Another important aspect is the implementation of dynamic adjustments based on real-time sensor feedback, which allow for optimal performance even if conditions change during the machining process.

Efficient tool path optimization offers several benefits. By minimizing the time and distance traveled by the tool, manufacturers can reduce wear and tear on the machine and save energy, resulting in cost savings. Waste reduction is also achieved through efficient tool paths, as unnecessary motions are eliminated, leading to higher material utilization. Moreover, optimizing tool paths for complex surfaces ensures that intricate geometries and contours are accurately machined, enhancing the overall quality of the finished product.

Dynamic adjustments based on real-time sensor feedback further enhance the efficiency and precision of CNC machining. These adjustments allow the machine to respond to changing conditions during the machining process, such as variations in material properties or tool wear. By adapting to these changes, the machine can maintain optimal performance and consistently produce high-quality parts.

Overall, optimizing tool paths in CNC programming is crucial for maximizing efficiency, minimizing waste and energy consumption, and achieving precise machining of complex surfaces. By harnessing the power of advanced programming techniques and real-time feedback, manufacturers can elevate the performance of their CNC machines and deliver exceptional results.

Benefits of Optimizing Tool Paths:

- Minimizes time and distance traveled by the tool

- Reduces wear and energy consumption

- Minimizes waste and increases material utilization

- Ensures accurate machining of complex surfaces

- Enables dynamic adjustments for optimal performance

Measurement Tools and Quality Control in CNC Machining

Accurate measurements and quality control are vital in CNC machining to ensure precision and consistency. This section explores the importance of measurement tools and quality control methodologies, such as Statistical Process Control (SPC) and Six Sigma, in achieving optimal results.

Measurement Tools

In CNC machining, various measurement tools play a crucial role in obtaining accurate measurements. Three commonly used tools include:

- Calipers: Calipers are versatile measurement tools used for taking precise measurements of dimensions such as length, width, and depth. They can be digital or analog, and their adjustable jaws allow for precise measurements of both external and internal features.

- Micrometers: Micrometers provide highly accurate measurements for small components. They consist of a calibrated screw mechanism that ensures precise readings, making them suitable for measuring dimensions within micrometer tolerances.

- CMMs (Coordinate Measuring Machines): CMMs are advanced measurement tools used for dimensional quality inspection. These machines use touch probes and laser scanners to measure complex 3D geometries accurately. CMMs play a vital role in ensuring the quality and adherence to design specifications.

Utilizing these measurement tools allows CNC machinists to verify part dimensions and ensure they align with the design specifications.

Quality Control Methodologies

Implementing quality control methodologies in CNC machining is essential to monitor and improve processes, leading to consistent quality and reduced defects. Two widely used methodologies are Statistical Process Control (SPC) and Six Sigma.

Statistical Process Control (SPC): SPC involves the collection and analysis of real-time data during CNC machining processes. By monitoring key process parameters, machinists can identify any variations or deviations from the desired specifications. SPC enables proactive intervention, minimizing the likelihood of defects and ensuring consistent quality.

Six Sigma: Six Sigma is a disciplined data-driven approach aimed at reducing variability and defects in manufacturing processes. This methodology focuses on statistical analysis and process improvement to achieve high levels of quality and efficiency. By applying Six Sigma principles, CNC machining operations can significantly reduce defects and enhance overall performance.

Combining measurement tools with quality control methodologies ensures that CNC machinists can maintain strict quality standards, minimize errors, and deliver reliable and accurate parts to their customers.

Next, we will explore the importance of continuous learning in CNC machining and the necessary skills to excel in this field.

The Importance of Continuous Learning in CNC Machining

Becoming an expert in CNC machining requires a lifelong commitment to continuous learning. In this ever-evolving field, staying up-to-date with evolving methodologies and emerging technologies is crucial for achieving CNC machining expertise. By embracing continuous learning, CNC programmers and operators can enhance their skills and knowledge, enabling them to deliver superior accuracy, efficiency, and quality in their work.

Continuous learning allows professionals in the CNC machining industry to remain at the forefront of advancements. New methodologies and techniques are constantly emerging, driven by technological advancements and industry demands. By actively seeking and embracing these changes, CNC professionals can adapt their practices and workflows to achieve the best results.

The Benefits of Continuous Learning

Continuous learning in CNC machining provides numerous benefits. Here are a few key advantages:

- Staying updated with the latest technological advancements and industry trends

- Gaining in-depth knowledge of evolving machining methodologies and techniques

- Improving efficiency by adopting new tools, software, and automation features

- Enhancing problem-solving and troubleshooting skills

- Expanding professional network through participation in industry events and forums

Continuous learning goes beyond formal education and extends to exploring various resources. For CNC professionals, it involves reading industry publications, attending workshops and conferences, participating in webinars, and engaging with online communities. Sharing experiences and insights with peers provides invaluable opportunities for growth and development.

Continual Improvement through Lifelong Learning

Lifelong learning is an ongoing journey of acquiring knowledge, improving skills, and expanding horizons. It demonstrates a proactive commitment to personal and professional growth. For CNC professionals, lifelong learning is the key to becoming proficient in their craft and staying ahead of the competition.

In the dynamic world of CNC machining, continuous learning enables individuals to adapt to evolving industry demands. It fosters a culture of innovation and excellence, ensuring that CNC programmers and operators are equipped to tackle complex challenges and deliver exceptional results.

Maintaining a Lifelong Commitment

To maintain a lifelong commitment to continuous learning in CNC machining, professionals can follow these strategies:

- Establish a learning routine: Allocate dedicated time to learn and explore new concepts, technologies, and techniques related to CNC machining.

- Engage in networking: Connect with fellow professionals, mentors, and industry experts for knowledge sharing and collaboration.

- Attend industry events: Participate in trade shows, conferences, and workshops to gain insights into emerging trends and technologies.

- Online learning platforms: Utilize online resources such as courses, tutorials, and webinars to expand knowledge and skillset.

- Stay informed: Regularly read industry publications, blogs, and forums to stay updated with the latest advancements and best practices in CNC machining.

By making continuous learning a priority, CNC professionals can unlock their full potential, take their expertise to new heights, and contribute to the advancement of CNC machining as a whole.

| Benefits of Continuous Learning in CNC Machining | Strategies for Lifelong Learning |

|---|---|

| – Staying updated with industry trends and technological advancements | – Establish a learning routine |

| – Gaining in-depth knowledge of evolving machining methodologies and techniques | – Engage in networking |

| – Improving efficiency through new tools and automation features | – Attend industry events |

| – Enhancing problem-solving and troubleshooting skills | – Utilize online learning platforms |

| – Expanding professional network | – Stay informed through industry publications |

Tips for Successful CNC Machine Programming

To ensure successful CNC machine programming, it’s essential to have a solid grasp of the basics. A thorough understanding of accurate machine specifications sets a strong foundation for efficient programming.

1. Solid Grasp of Basics

To excel in CNC machine programming, it’s crucial to have a solid grasp of the fundamentals. This includes understanding G-codes, M-codes, and T-codes, as well as proficiency in using CAD/CAM software. Mastery of mathematical concepts like geometry, trigonometry, and calculus is also essential for accurate tool paths and optimization. Additionally, familiarity with measurement tools such as calipers, micrometers, and CMMs ensures precise measurements and quality control.

2. Program Optimization

Optimizing CNC programs plays a significant role in enhancing efficiency and productivity. Fine-tuning and customizing feed rates can greatly improve machining performance. By minimizing time and distance traveled by the tool, wear and energy consumption can be reduced. Additionally, optimizing tool paths for complex surfaces involves calculating gradients and curvatures, further enhancing precision.

3. Attention to Detail

Attention to detail is crucial in CNC machine programming to ensure accuracy and quality. Error-checking and peer reviews help catch and rectify mistakes, leading to improved programming accuracy. Thoroughly reviewing program logic and verifying machine settings can prevent costly errors and minimize downtime.

By following these CNC machine programming tips, programmers can achieve superior results in terms of efficiency, accuracy, and overall quality in their machining operations.

Conclusion

Precision and accuracy are paramount in the art of CNC programming. By thoroughly understanding the essential components of CNC machine mechanics, programmers can optimize their programming techniques for superior results. Attention to detail, continuous skill development, and strict adherence to quality control measures are the pillars of success in CNC machining.

Throughout this article, we have explored the significance of CNC programming in achieving accurate machining operations. From crafting precise sets of instructions using G-code to transmitting them to CNC machines, the programming process is a critical aspect of the manufacturing journey. By employing best practices and continuously learning, CNC programmers can refine their skills and maximize the potential of CNC machines.

It is essential to grasp the intricacies of CNC machine mechanics, including the machine bed, spindles and tooling, linear motion systems, control systems, and feedback systems. These components work together to ensure stability, precise movement, and optimal performance of CNC machines. By understanding their functions and capabilities, programmers can harness the power of CNC machines to achieve unmatched accuracy.

As we conclude, let us emphasize the importance of continuous learning in the field of CNC machining. With ever-evolving methodologies and technologies, staying up-to-date is crucial for maintaining expertise. By embracing a lifelong commitment to learning and implementing CNC programming tips, programmers can achieve superior accuracy, efficiency, and quality in their work.