CNC experts can effectively troubleshoot common problems by following these five key tips: Regularly calibrate and align the machine to maintain accuracy and prevent positioning errors; implement proper tool management practices, including frequent inspections and replacements, to avoid tool breakage and poor surface finishes; monitor and maintain coolant levels and quality to prevent overheating and ensure optimal cutting performance; carefully review and optimize G-code programs to eliminate syntax errors and inefficient toolpaths; and conduct routine preventive maintenance, such as lubricating moving parts and cleaning sensors, to minimize unexpected breakdowns and extend machine life.

By focusing on these critical areas, CNC operators can significantly reduce downtime, improve part quality, and enhance overall productivity in their machining operations. Additionally, keeping detailed logs of machine performance and maintenance activities can help identify recurring issues and facilitate more efficient problem-solving in the future.

- Solving CNC problems requires expertise and knowledge of troubleshooting techniques.

- Proper maintenance and regular cleaning are crucial for the smooth operation of CNC machines.

- Using the right tools and settings ensures high-quality results and prevents issues.

- Accurate programming is essential to avoid errors and achieve flawless products.

- Understanding the step-by-step tool change process helps diagnose and resolve issues effectively.

Understanding CNC Machines: Basics and Function

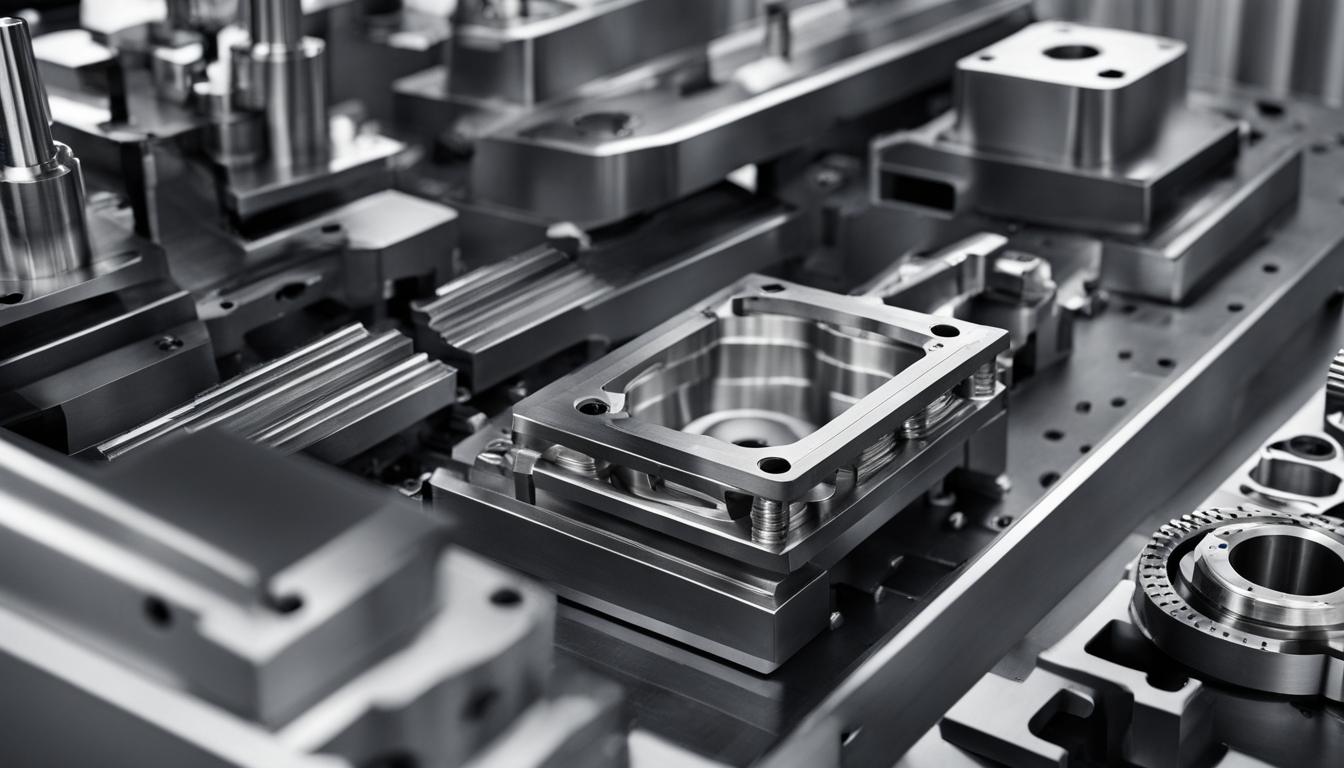

Before diving into troubleshooting, it’s crucial to have a clear understanding of CNC machines and how they work. A CNC machine, short for Computer Numerical Control machine, is an electro-mechanical device that utilizes computer programming to control various machine-shop tools and devices. These machines manipulate the tools and materials to transform raw materials into finished products with high precision and accuracy.

CNC machines were first developed in the 1940s and have since evolved to use digital computer processing methods, allowing for more complex and intricate operations. They have revolutionized the manufacturing and machining industries by automating tasks that were previously conducted manually, resulting in improved efficiency and productivity.

These versatile machines can work with a wide array of materials, including metals like aluminum and steel, as well as wood and plastics. Their ability to handle different materials makes them indispensable in various industries, such as aerospace, automotive, and construction.

By utilizing computer programming, CNC machines can execute precise movements and instructions, leading to consistent and repeatable outcomes. The programming language used in CNC machine control is typically G-code, a standardized programming language that defines the tool paths, speeds, and feed rates for the machine.

Overall, CNC machines offer unmatched accuracy, repeatability, and flexibility, making them essential tools in modern manufacturing and machining processes. Understanding how these machines function and the principles behind their operation is crucial for both troubleshooting and optimizing their performance.

Common Issues in CNC Machines: Causes and Impact

Despite their efficiency, CNC machines are not immune to problems. Various factors can lead to issues in CNC machines. These common issues can significantly impact the accuracy, precision, and overall performance of CNC machines. In this section, we will explore the causes and the impact of these issues.

Poor or Improper Maintenance

One of the primary causes of problems in CNC machines is poor or improper maintenance. When the machine is not adequately maintained, it can lead to the build-up of dirt and debris. This build-up can result in inaccurate instructions and material movement during the cutting process. It is crucial to follow a regular maintenance schedule and ensure proper cleaning of the machine components to prevent these issues.

Improper Settings or Tools

Using improper settings or tools is another common cause of problems in CNC machines. Blunt or incorrectly sized cutting tools can result in burn marks, rough edges, and visible cutting marks on the material. It is essential to regularly inspect and replace worn or blunt tools to maintain optimal performance. Additionally, ensuring the correct settings for coolant or lubricant function and adjusting tool speeds can help address issues related to tools and settings.

Incorrect Programming

Incorrect programming is yet another factor that can lead to problems in CNC machines. When the programming is inaccurate, it can result in errors in the final product. Providing comprehensive training to employees on CNC machine programming is essential to avoid these errors. Regularly checking and verifying the programming codes can help identify and rectify any errors, ensuring the production of high-quality products.

These common issues in CNC machines can have a significant impact on the efficiency and productivity of manufacturing and machining processes. Addressing these issues promptly and effectively through troubleshooting techniques is crucial to ensuring smooth operations and optimal performance.

Troubleshooting Tip 1: Proper Maintenance and Cleaning

Proper maintenance and cleaning are essential for the smooth operation of CNC machines. Regular cleaning and lubrication prevent dirt and debris build-up, ensuring accurate instructions and preventing material movement during cutting.

Cleaning the components and ensuring proper lubrication of machine parts prevent sticking, overheating, and air blockage issues. Following a regular maintenance schedule and checking the cleanliness and lubrication of the CNC machine are important troubleshooting steps to address common issues.

Regular Maintenance Checklist for CNC Machines:

| Tasks | Frequency |

|---|---|

| Inspecting and cleaning the cutting tools | Weekly |

| Removing dirt and debris from the machine components | Daily |

| Applying lubrication to machine parts | Monthly |

| Checking the coolant and coolant levels | Weekly |

| Verifying the alignment of the machine axes | Quarterly |

| Inspecting electrical connections and cables | Monthly |

Following these maintenance practices will contribute to the longevity and optimal performance of your CNC machine. By keeping the machine clean and well-lubricated, you can minimize issues caused by dirt accumulation or component malfunctions.

Troubleshooting Tip 2: Use the Right Tools and Settings

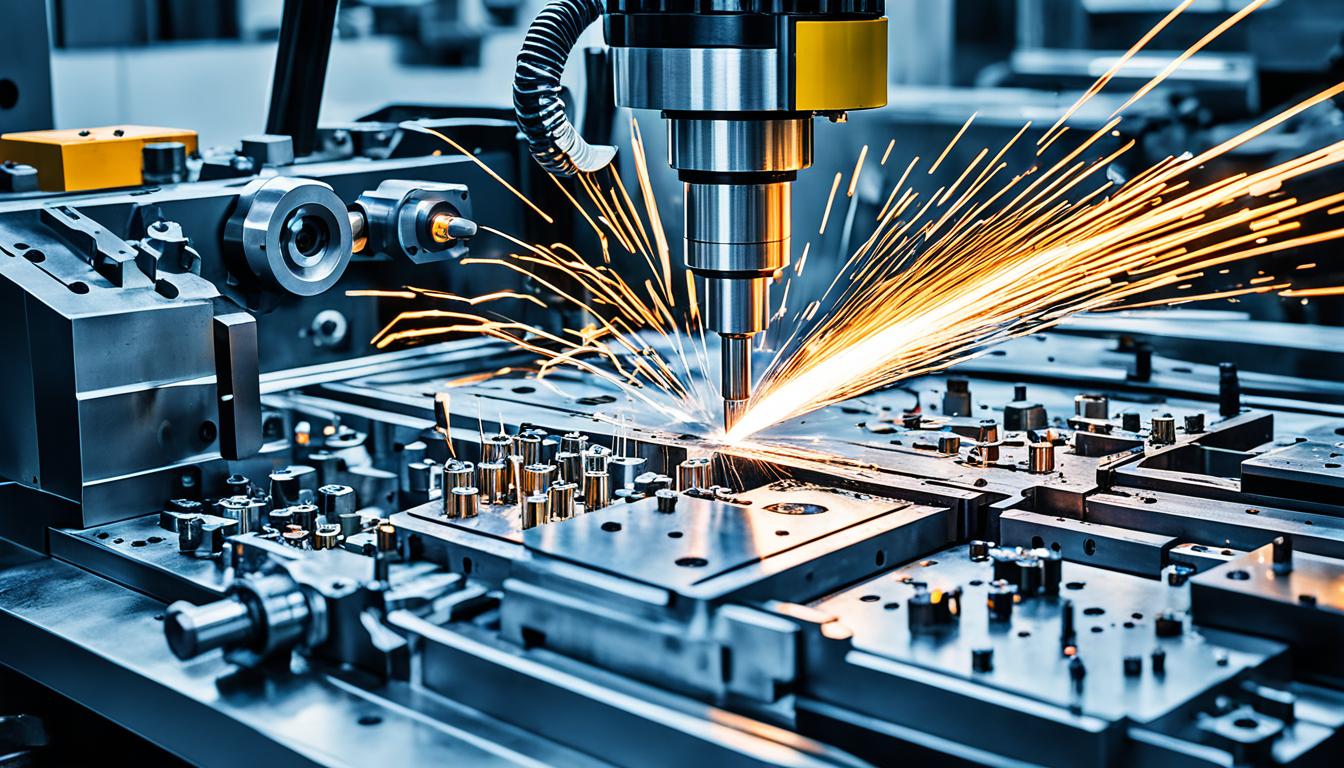

When it comes to CNC machine troubleshooting, using the correct cutting tools and settings is of utmost importance. Choosing the wrong tools or having incorrect settings can result in rough edges, burn marks, and subpar material finishes, leading to unsatisfied customers and wasted resources.

To avoid these issues, CNC experts should regularly inspect their tools and replace any worn or blunt ones. Keeping the tools in optimal condition ensures precise cuts and maintains the overall performance of the machine. Additionally, experts must pay attention to the coolant or lubricant function to ensure proper tool cooling and reduce friction during the machining process.

Adjusting the tool speeds according to the material being worked on is another crucial aspect of CNC troubleshooting. Different materials require different cutting speeds to achieve the desired results. Experts can refer to the manufacturer’s recommendations or conduct test runs to determine the ideal tool speeds for each specific material.

By using the right tools and settings, CNC professionals can enhance the quality and accuracy of their machining processes, delivering outstanding results to their clients.

Recommended Tool Types and Settings for Common Materials

| Material | Recommended Tool Type | Recommended Speed (RPM) |

|---|---|---|

| Aluminum | Carbide End Mill | 10,000-15,000 |

| Steel | High-Speed Steel Drill Bit | 500-1,200 |

| Wood | Straight Router Bit | 18,000-24,000 |

| Plastics | Single-Flute Spiral Upcut End Mill | 14,000-16,000 |

Troubleshooting Tip 3: Accurate Programming

Programming errors can have significant consequences in CNC machining, often resulting in flawed products. To avoid such issues, it is essential to provide comprehensive training to employees in CNC machine programming. By equipping operators with the necessary skills and knowledge, they can effectively navigate the intricacies of CNC programming, minimizing the occurrence of error.

Regularly checking and verifying programming codes is a crucial step in troubleshooting. It allows operators to identify and rectify any errors in the code promptly. Instead of resorting to shortcuts like restarting the machine, operators should prioritize fixing coding issues directly to ensure efficient troubleshooting and maintain production continuity.

Benefits of Accurate Programming

Accurate programming offers several advantages to CNC machining operations:

- Increased Product Quality: Precise programming ensures the production of high-quality products with minimal defects.

- Enhanced Efficiency: Accurate coding optimizes machine efficiency, reducing downtime caused by programming errors.

- Time and Cost Savings: By avoiding rework and scrap caused by faulty programming, businesses can save valuable time and resources.

- Consistency in Output: Accurate programming contributes to uniformity in product dimensions and specifications, essential for meeting customer requirements.

Example

Let’s take a look at a table showcasing the impact of accurate programming on CNC machining:

| Scenario | Consequences |

|---|---|

| Accurate Programming | Produces precise and high-quality parts |

| Inaccurate Programming | Results in flawed parts, requiring rework or scrap |

| Downtime and increased production costs | |

| Potential damage to machine components |

As evident from the example, accurate programming plays a crucial role in ensuring a smooth and efficient CNC machining process, while inaccurate programming can lead to expensive repercussions.

To summarize, accurate programming is an essential troubleshooting tip for CNC experts. Providing comprehensive training, regularly checking and verifying programming codes, and prioritizing proper coding practices can minimize errors and facilitate optimal CNC machine performance.

Troubleshooting Tip 4: Step-by-Step Tool Change Process

Automatic tool change is a critical process in CNC machining. Understanding the step-by-step tool change sequence is essential for troubleshooting any issues during this process. By familiarizing oneself with the axes movement, spindle alignment, door opening, magazine pot position, and tool engagement steps, experts can effectively identify and diagnose problems in the tool change process.

Here is a breakdown of the step-by-step tool change process in CNC machining:

- Axes Movement: The CNC machine moves the axes to a predefined position to ensure the tool change can be executed smoothly without any collisions or interferences.

- Spindle Alignment: The spindle is aligned with the tool changer mechanism to ensure precise and accurate tool engagement.

- Door Opening: The door covering the tool magazine or turret opens, providing access to the tools.

- Magazine Pot Position: The CNC machine positions the tool magazine or turret in a specific location to allow easy access for tool selection or replacement.

- Tool Engagement: The CNC machine engages the selected tool, securely locking it into the spindle for the machining process.

By following this troubleshooting tip and having a clear understanding of the tool change process, experts can effectively spot and resolve issues that may arise during the tool change sequence in CNC machining.

Summary of Troubleshooting Tip 4: Step-by-Step Tool Change Process

| Step | Process |

|---|---|

| Axes Movement | The CNC machine moves the axes to a predefined position. |

| Spindle Alignment | The spindle is aligned with the tool changer mechanism. |

| Door Opening | The door covering the tool magazine or turret opens. |

| Magazine Pot Position | The tool magazine or turret is positioned for easy access. |

| Tool Engagement | The selected tool is securely locked into the spindle. |

Troubleshooting Tip 5: Power Supply and Electrical Checks

Power supply problems can significantly impact the operation of CNC machines. When troubleshooting power-related issues, it’s important to conduct basic checks on the power supply system. This includes inspecting connectors, fuses, emergency stops, and electrical cabinet modules.

One crucial component to inspect is the spindle motor, as it plays a vital role in the functioning of the DC motor. By checking the spindle motor, brushes, and electrical connections, experts can identify and resolve problems that may be affecting the motor’s performance.

Another critical step in troubleshooting power-related issues is examining various components such as the conveyor, overtravels, interlock mechanisms, and power supplies. These components can contribute to problems related to the emergency stop function. By thoroughly inspecting and evaluating these elements, experts can pinpoint the source of the issue and implement appropriate solutions.

Conducting regular power supply and electrical checks is essential to maintain the smooth operation of CNC machines. By addressing and resolving power-related problems, CNC professionals can ensure optimal performance and maximize productivity.

| Power Supply and Electrical Checks | Action |

|---|---|

| Inspect connectors | Clean and secure loose connections |

| Check fuses | Replace any blown fuses |

| Examine emergency stops | Ensure they are functioning properly |

| Inspect electrical cabinet modules | Look for any signs of damage or malfunction |

| Check spindle motor | Inspect brushes and electrical connections |

| Inspect conveyor and overtravels | Ensure they are functioning correctly |

| Examine interlock mechanisms | Check for proper engagement |

| Inspect power supplies | Look for any signs of malfunction or inadequate power output |

Learn and Improve: Continuous Optimization

Troubleshooting CNC machines is an ongoing process that requires continuous learning and improvement. As CNC experts, it is crucial to review and evaluate the effectiveness of our troubleshooting efforts after resolving issues. This allows us to identify areas for improvement and optimize the performance of CNC machines.

One key aspect of continuous optimization is investing in additional training. By staying updated on the latest technologies and techniques, we can enhance our troubleshooting skills and tackle complex problems more effectively. Regular training sessions and workshops provide valuable insights and help us stay ahead in the ever-evolving field of CNC machining.

Another important aspect is making adjustments in maintenance procedures. By closely monitoring machine performance and analyzing the root causes of recurring problems, we can identify opportunities to optimize maintenance routines. This can involve applying new lubrication techniques, implementing preventive maintenance schedules, or enhancing cleaning processes to minimize the risk of future issues.

Lastly, sharing knowledge and experiences with colleagues plays a crucial role in continuous optimization. By fostering a collaborative environment, we can learn from each other’s successes and challenges. Discussions, brainstorming sessions, and knowledge-sharing platforms provide opportunities for insights and innovative solutions. Through collective efforts, we can create problem-free CNC machining operations and further enhance the overall efficiency of our processes.