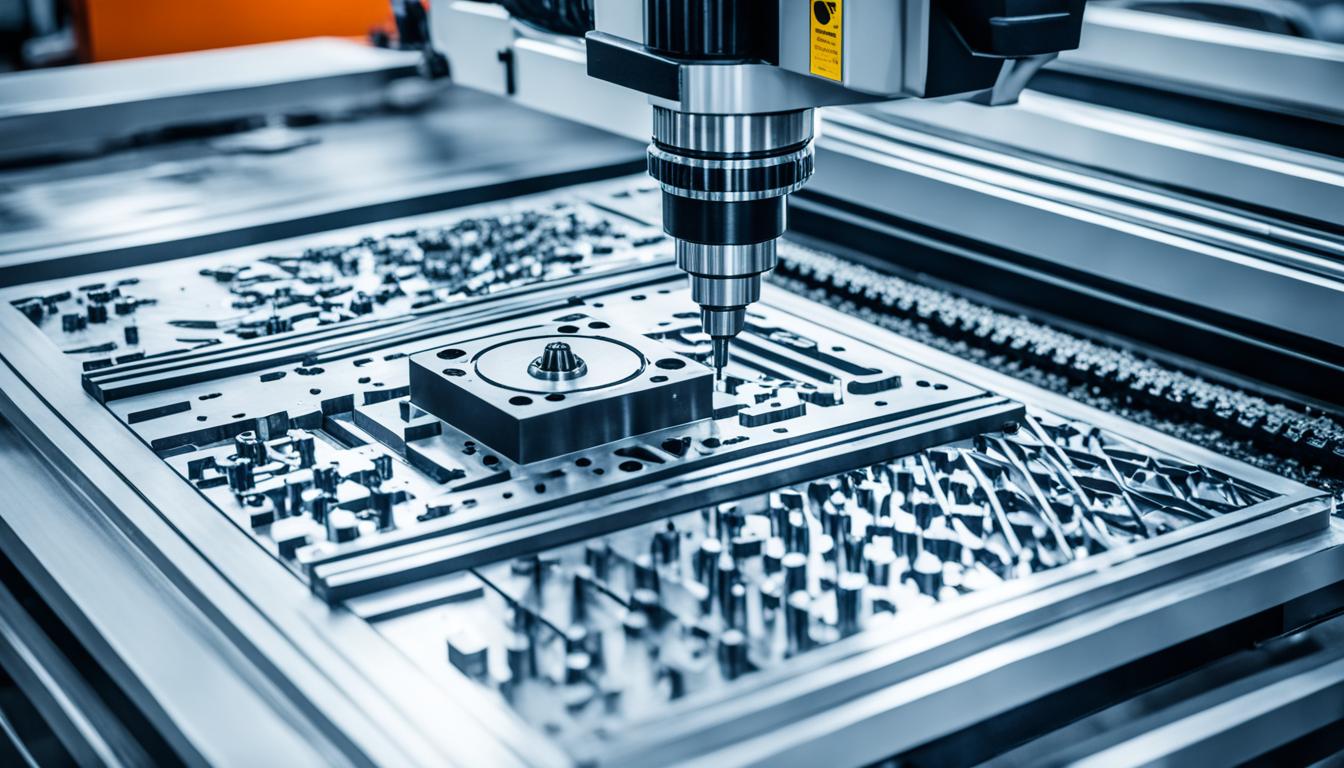

Implementing cost-effective strategies in CNC machining can significantly reduce expenses without compromising quality. Optimize material usage by nesting parts efficiently and selecting appropriate stock sizes to minimize waste. Streamline designs for manufacturability, reducing complexity and machining time. Leverage high-speed machining techniques and advanced tooling to increase productivity and reduce cycle times.

Consider alternative materials that offer similar properties at lower costs. Utilize CAM software to simulate and refine machining processes, minimizing errors and optimizing tool paths. Implement preventive maintenance schedules to reduce downtime and extend machine life. These strategies, when applied thoughtfully, can lead to substantial cost savings in CNC machining operations, improving overall profitability and competitiveness in the manufacturing industry.

- Implementing cost-cutting strategies can optimize budgeting in CNC machining.

- Reducing expenses without compromising quality or productivity is essential.

- Valuable insights from reliable sources provide practical techniques for cost-cutting.

- Smart financial planning is crucial for CNC machining success.

- Optimizing budgeting helps businesses achieve financial prudence.

Understanding the Importance of Budgeting in CNC Machining

Smart budgeting plays a crucial role in CNC machining as it helps businesses reduce costs and optimize their expense management. By implementing effective budgeting strategies, businesses can identify areas for cost reduction and allocate resources more efficiently. Proper budget planning is vital for achieving financial prudence in CNC machining and ensuring that expenses are optimized while maintaining quality and productivity.

CNC machining, a technology-driven manufacturing process, involves the use of computer numerical control (CNC) machines to automate various machining operations. These machines offer unparalleled precision and efficiency, enabling businesses to produce complex components with ease. However, the cost associated with CNC machining can be significant, making it essential for businesses to adopt smart budgeting practices to reduce expenses and maximize profitability.

Effective budgeting in CNC machining involves a thorough analysis of production costs, material expenses, equipment maintenance, and labor costs. By understanding the various cost drivers, businesses can identify opportunities for cost reduction and develop strategies to optimize their budget. Let’s explore some key insights into the importance of budgeting in CNC machining:

1. Identifying Cost Reduction Opportunities

- By closely examining the CNC machining process and associated expenses, businesses can identify areas where cost reduction is possible.

- These areas may include optimizing machine utilization, streamlining production workflows, minimizing material waste, and optimizing tool life.

- Through smart budgeting practices, businesses can prioritize these areas and allocate resources more effectively, resulting in significant cost savings.

2. Allocating Resources Efficiently

- Effective budgeting allows businesses to allocate resources in a way that aligns with their strategic goals and objectives.

- By having a clear understanding of the budget, businesses can make informed decisions about resource allocation, ensuring that resources are used efficiently and effectively.

- Proper allocation of resources helps optimize productivity, minimize waste, and enhance overall operational efficiency, leading to cost reduction in CNC machining.

3. Planning for Future Expenses

- Smart budgeting in CNC machining involves not only managing current expenses but also planning for future costs.

- Businesses need to anticipate future material price fluctuations, equipment maintenance and upgrade costs, and workforce requirements.

- By incorporating these factors into the budgeting process, businesses can ensure that they have adequate funds to cover future expenses without compromising quality or productivity.

4. Streamlining Cost Monitoring and Control

- Effective budgeting provides businesses with a framework for monitoring and controlling costs.

- It allows for regular tracking of actual expenses against the budget, enabling businesses to identify any deviations and take corrective actions.

- By implementing robust cost monitoring practices, businesses can quickly identify cost overruns and implement measures to reduce expenses, contributing to cost reduction in CNC machining.

By understanding the importance of budgeting in CNC machining and implementing effective cost-cutting strategies, businesses can optimize their expenses, improve profitability, and gain a competitive edge in the market. The next section will delve into the process of defining cost-cutting objectives and strategies, which is essential for successful budgeting in CNC machining.

Defining Your Cost-Cutting Objectives and Strategies

Before implementing cost-cutting strategies, it is essential to define clear objectives and strategies. By doing so, businesses can make informed decisions about resource allocation and focus on projects that deliver the highest potential returns. This involves analyzing market needs, setting goals, and prioritizing projects with strategic importance.

Aligning cost-cutting efforts with business objectives ensures that budget planning is aligned with the organization’s goals. Collaboration with finance teams can further enhance cost management efforts, ensuring that funds are used efficiently and effectively.

Periodic reviews play a crucial role in refining the budgeting process. By assessing the outcomes of cost-cutting strategies, businesses can identify areas for improvement, optimize resource allocation, and adjust their objectives and strategies accordingly.

Benefits of Defining Cost-Cutting Objectives and Strategies:

- Optimized Budget Planning: Clear objectives and strategies enable businesses to allocate resources more effectively, ensuring that funds are utilized in a way that aligns with their goals.

- Informed Decision-Making: By understanding the strategic importance of projects, businesses can prioritize their cost-cutting efforts, focusing on areas that deliver the highest potential returns.

- Refined Budgeting Process: Periodic reviews allow businesses to evaluate the outcomes of their cost-cutting strategies and make necessary adjustments, ensuring continuous improvement in budget planning.

Key Elements in Defining Cost-Cutting Objectives and Strategies

| Element | Description |

|---|---|

| Market Analysis | Thoroughly assess market needs and demands to identify opportunities for cost reduction. |

| Goal Setting | Set clear, measurable objectives that align with the organization’s overall strategy and financial targets. |

| Project Prioritization | Determine the strategic importance of projects and allocate resources accordingly to maximize cost-cutting efforts. |

| Collaboration with Finance Teams | Work closely with finance teams to ensure efficient and effective use of funds. |

| Periodic Reviews | Regularly evaluate the outcomes of cost-cutting strategies and refine objectives and strategies as needed. |

Defining your cost-cutting objectives and strategies is a crucial first step to optimize budget planning and achieve smart cost management in CNC machining. By aligning your cost-cutting efforts with business objectives and periodically reviewing your strategies, you can ensure that resources are allocated effectively and achieve significant cost reductions.

Estimating and Planning Your R&D Costs

Estimating and planning the costs of researching, designing, prototyping, testing, and launching products is crucial for effective budgeting in CNC machining. By accurately estimating project costs, businesses can ensure that their budget aligns with their goals and optimizes resource allocation. Various estimation techniques can be utilized to improve accuracy, such as:

- Top-down estimation: A high-level approach that uses historical data and industry benchmarks to estimate costs.

- Bottom-up estimation: A detailed approach that involves breaking down the project into smaller components and estimating costs for each individual part.

- Parametric estimation: A method that uses mathematical models and historical data to estimate costs based on specific parameters.

Once the costs are estimated, businesses can plan their R&D budget considering factors like goals, scope, schedule, resources, and risks. This planning process ensures that resources are allocated appropriately and minimizes the potential for cost overruns. Here is a breakdown of the key factors to consider when planning your R&D budget:

- Goals: Clearly define your project goals and align them with your budget to ensure that you allocate resources effectively.

- Scope: Determine the scope of your project and break it down into manageable tasks to estimate costs accurately.

- Schedule: Create a timeline for your project and consider the duration of each phase to plan resource allocation and expenses.

- Resources: Identify the resources required for your project, including personnel, equipment, materials, and third-party services.

- Risks: Assess potential risks and establish contingency plans to mitigate unforeseen expenses and maintain budget stability.

A well-planned budget is essential for cost management in CNC machining, ensuring that resources are utilized efficiently and enabling businesses to achieve their objectives effectively.

Managing Your R&D Budget and Tracking Spending

Effective management of your R&D budget is essential to optimize expenses in CNC machining. By tracking spending, reviewing performance, analyzing variances, and adjusting the budget accordingly, businesses can achieve expense optimization and improve cost control in their operations. To facilitate this process, various software tools like accounting tools, project management tools, and spreadsheets can be utilized to track and manage expenses efficiently.

Monitoring actual spending against the planned budget is crucial for identifying areas where adjustments need to be made and resources reallocated. Regular reviews and adjustments ensure that the budget remains aligned with business goals and market conditions, allowing businesses to make informed decisions regarding expense optimization and budget planning.

Expense Tracking and Performance Review

By implementing comprehensive expense tracking mechanisms, businesses can gain visibility into their spending patterns and identify opportunities for cost reduction. Analyzing expenditures and their impact on project outcomes enables businesses to make informed decisions regarding resource allocation, ensuring that budgets are optimized for maximum efficiency.

Regular performance reviews allow businesses to assess the effectiveness of their spending and identify areas for improvement. By evaluating key performance indicators (KPIs) and analyzing variances against budgeted targets, businesses can make data-driven decisions to optimize their expenses and streamline their budget planning for CNC machining.

Utilizing Software Tools for Expense Management

Software tools like accounting applications, project management platforms, and spreadsheets are valuable resources for managing R&D budgets and tracking spending. These tools provide real-time visibility into expenses, facilitate collaboration, and enable data analysis for better decision-making. They offer features such as budget tracking, cost allocation, and expense categorization, simplifying the budget management process.

Having a centralized system for expense management ensures accuracy, transparency, and accountability, making it easier to identify areas of overspending or potential cost savings. With real-time data and analytics, businesses can make timely adjustments and optimize their budgets to align with their financial goals and operational objectives.

Example Monthly Expense Tracking Table:

| Expense Category | Planned Budget | Actual Expense | Variance |

|---|---|---|---|

| Raw Materials | $10,000 | $8,500 | $1,500 Favorable |

| Machine Maintenance | $5,000 | $6,200 | $1,200 Adverse |

| Research & Development | $15,000 | $14,800 | $200 Favorable |

| Employee Training | $3,000 | $3,500 | $500 Adverse |

| Utilities | $2,500 | $2,400 | $100 Favorable |

This table provides an example of a monthly expense tracking report for a CNC machining business. It showcases the planned budget for each expense category, the actual expenses incurred, and the variance between the two. Such a table helps businesses track their spending, review their performance, and make informed decisions to optimize their budgets.

In summary, effective management of your R&D budget and tracking spending is essential for expense optimization and budget planning in CNC machining. By utilizing software tools for expense management, monitoring actual spending, and reviewing performance, businesses can make data-driven decisions to optimize their budgets and achieve cost savings.

Optimizing Your R&D Budget for Cost Savings

To achieve maximum cost savings in CNC machining, it is crucial for businesses to optimize their research and development (R&D) budget. By aligning the budget with the product vision, customer needs, and business objectives, companies can strategically allocate resources and invest in projects that offer high returns. Moreover, leveraging feedback from internal and external sources allows businesses to test assumptions, validate hypotheses, and further optimize their R&D budget.

Allocation of Resources

Strategic resource allocation is key to optimizing the R&D budget and achieving cost reduction. By identifying and prioritizing projects that align with the company’s long-term goals, businesses can allocate resources effectively. This involves assessing the potential return on investment (ROI) for each project and considering the market demand and growth opportunities.

Data-Driven Decision Making

Data-driven decision making plays a crucial role in optimizing the R&D budget. By collecting and analyzing data from various sources, businesses can gain insights into market trends, customer preferences, and industry advancements. This allows them to make informed decisions, focus resources on high-potential projects, and eliminate wasteful spending.

Continuous Evaluation and Reallocation

Continuous evaluation and reallocation of resources are essential for cost-saving techniques in CNC machining. Monitoring the progress and impact of projects enables businesses to make timely adjustments to the budget. Regular reviews, performance assessments, and milestones tracking help identify areas where resources need to be reallocated for maximum cost savings.

Collaboration and Innovation

Collaboration between cross-functional teams fosters innovation and cost reduction. By involving experts from various departments, businesses can benefit from diverse perspectives and ideas. This collaboration leads to the development of innovative solutions, optimized processes, and ultimately, significant cost savings.

| Benefits of Optimizing R&D Budget | Cost Reduction Techniques |

|---|---|

| 1. Maximizes ROI | 1. Streamlining processes |

| 2. Enhances resource allocation | 2. Implementing lean methodologies |

| 3. Boosts innovation | 3. Outsourcing non-core activities |

| 4. Improves time-to-market | 4. Automation of repetitive tasks |

| 5. Mitigates financial risks | 5. Negotiating supplier contracts |

By optimizing their R&D budget, businesses can unlock significant cost savings in CNC machining. From strategic resource allocation to data-driven decision making and collaboration, adopting these cost-saving techniques ensures efficient budgeting, improved productivity, and sustainable growth.

The Hidden Costs of Low-Quality Components

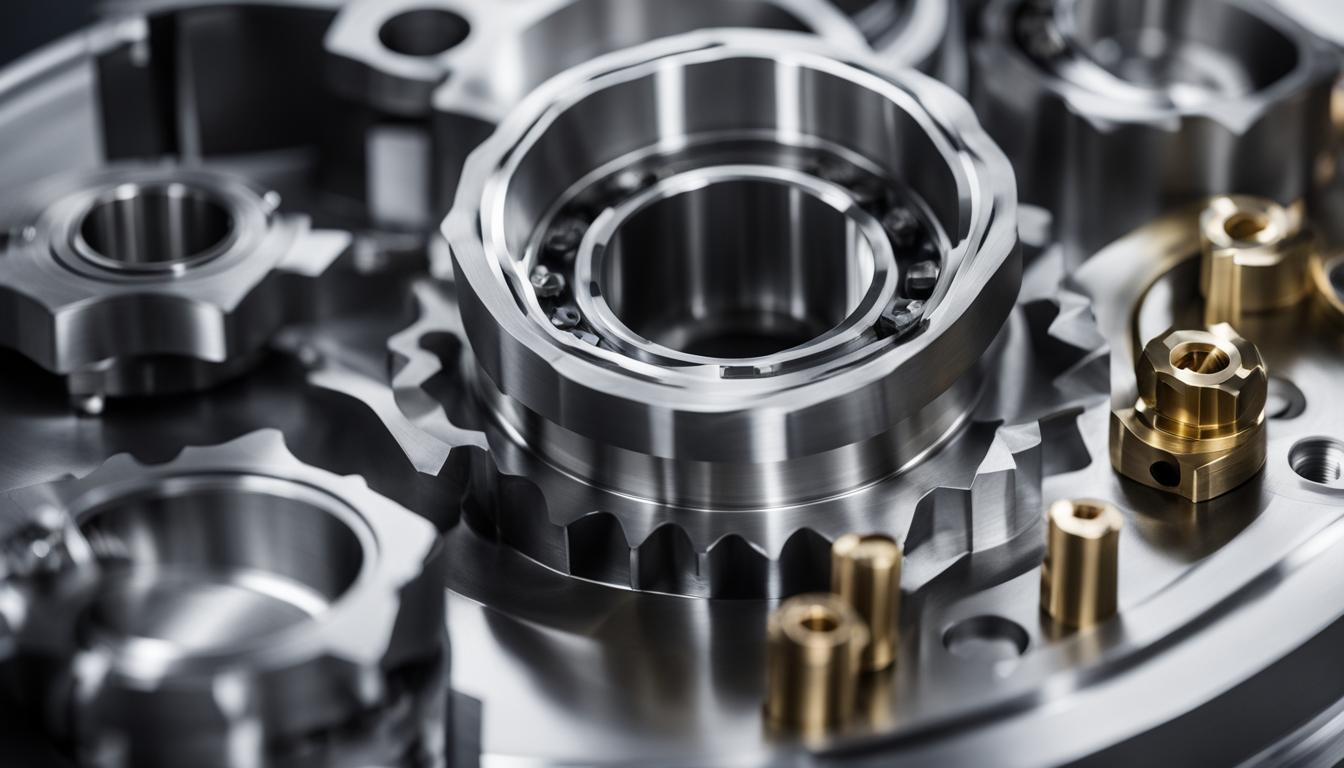

While cost reduction is a significant consideration in component manufacturing, it is essential to avoid solely focusing on low cost. Opting for low-quality components to save on expenses can lead to hidden costs that can severely impact businesses in the long run.

Low-quality components are more prone to issues such as increased downtime, frequent breakdowns, and the need for costly repairs or replacements. These expenses can quickly add up and outweigh any initial savings from choosing cheaper components. Therefore, it is crucial to prioritize quality over low cost to ensure the reliability and performance of the final product.

Industries where safety and reliability are paramount, such as automotive and aerospace, place great value on high-quality components. Quality components provide consistent performance and reduce the risk of failures or malfunctions. By investing in quality components, businesses can not only minimize long-term costs but also enhance their reputation and gain a competitive advantage in the market.

It is important for component manufacturers to consider the long-term implications of their choices. While low-cost alternatives may seem tempting initially, the potential consequences of compromised quality can outweigh any short-term benefits. By prioritizing quality in component manufacturing, businesses can deliver reliable products that meet customer expectations and stand the test of time.

Importance of Reliability and Long-Term Cost Savings

Investing in quality components not only ensures reliability but also leads to long-term cost savings. High-quality components are more durable and reliable, reducing maintenance expenses and extending the lifespan of products. By using reliable components, businesses can decrease the need for frequent replacements, further reducing costs over time.

Moreover, high-quality components provide a competitive advantage by enabling innovation. Manufacturers can explore new possibilities in product design and functionality by investing in components with unique features and improved materials, leading to innovative and high-performing products that stand out in the market.

Long-Term Cost Savings

Durable and reliable components contribute to long-term cost savings in several ways:

- Reduction in maintenance expenses: Quality components experience fewer failures, reducing the need for costly repairs or replacements.

- Extended product lifespans: Reliable components prolong the lifespan of products, allowing businesses to generate revenue from them for an extended period.

- Decreased need for replacements: High-quality components have a longer lifespan, minimizing the need for frequent replacements and associated costs.

Competitive Advantage through Innovation

High-quality components enable manufacturers to innovate and differentiate their products from competitors. By investing in components with unique features and improved materials, businesses can create innovative products that meet customer demands and preferences. Innovative products are often perceived as higher value, giving businesses a competitive edge in the market. Furthermore, innovation can open up new market opportunities and attract new customers, further enhancing a company’s competitive advantage.

| Benefits of Quality Components | Impact on Cost Savings and Competitive Advantage |

|---|---|

| Durable and reliable | Reduces maintenance expenses, extends product lifespans, and decreases the need for frequent replacements. |

| Enables innovation | Provides a competitive edge, attracts customers, and opens up new market opportunities. |

Considerations for Responsible Manufacturing

In the pursuit of cost reduction, businesses must not overlook the environmental and ethical implications of their manufacturing practices. Incorporating environmental sustainability and ethical practices into the production process is crucial for meeting customer expectations and contributing to a more sustainable future.

One way businesses can prioritize environmental sustainability is by using eco-friendly materials and processes in their manufacturing operations. Quality components that are produced using sustainable materials not only reduce the carbon footprint but also resonate with consumers who value responsible and sustainable products.

In addition to environmental considerations, it is important for businesses to ensure ethical practices in their supply chain. Responsible component manufacturers provide comprehensive documentation of material origins, ensuring traceability and avoiding materials sourced from conflict areas. This commitment to ethical sourcing demonstrates a commitment to integrity and social responsibility.

By embracing environmental sustainability and ethical practices, businesses can align their manufacturing processes with evolving customer expectations. This not only enhances their brand reputation but also positions them as leaders in responsible manufacturing. Ultimately, incorporating these considerations into their operations not only drives cost reduction but also contributes to a more sustainable and ethical future.