A Horizontal Machining Center (HMC) is a sophisticated computer-controlled machine tool designed for precision manufacturing of complex parts. It features a horizontally oriented spindle that holds cutting tools, allowing for efficient machining of large, heavy workpieces from multiple angles. HMCs excel in high-volume production environments due to their ability to perform various operations like milling, drilling, boring, and tapping in a single setup.

The horizontal configuration offers improved chip evacuation, better coolant flow, and enhanced tool life compared to vertical machining centers. HMCs typically incorporate a pallet changer system, enabling continuous operation by swapping workpieces while the machine is running. This design maximizes productivity and reduces downtime. Advanced HMCs may include features such as multi-axis capabilities, automatic tool changers, and integrated quality control systems, making them ideal for industries like aerospace, automotive, and heavy equipment manufacturing where precision and efficiency are paramount.

What Does a Horizontal Machining Center Refer To?

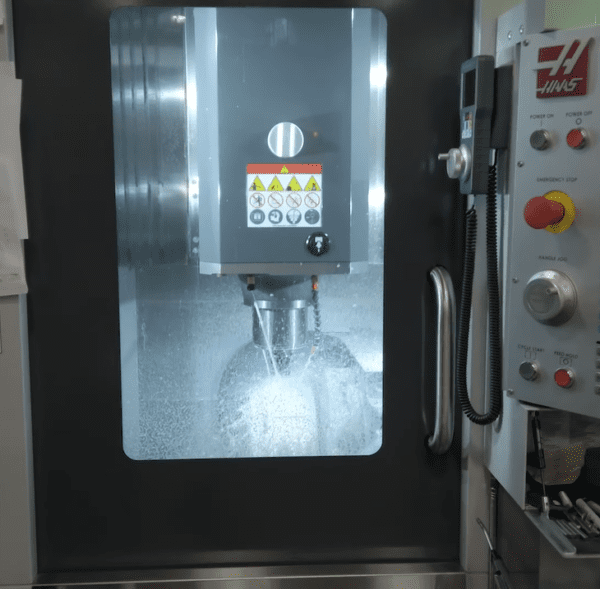

In horizontal milling, various cutting tools are used to extract metal from a workpiece. This process takes place on a horizontal machining center (HMC) where the spindle aligns parallel to both the worktable and the ground. In this setup, the tool protrudes from the side of the holder, machining the workpiece’s side. This allows the metal chips to fall freely, eliminating the need to clear them from the table.

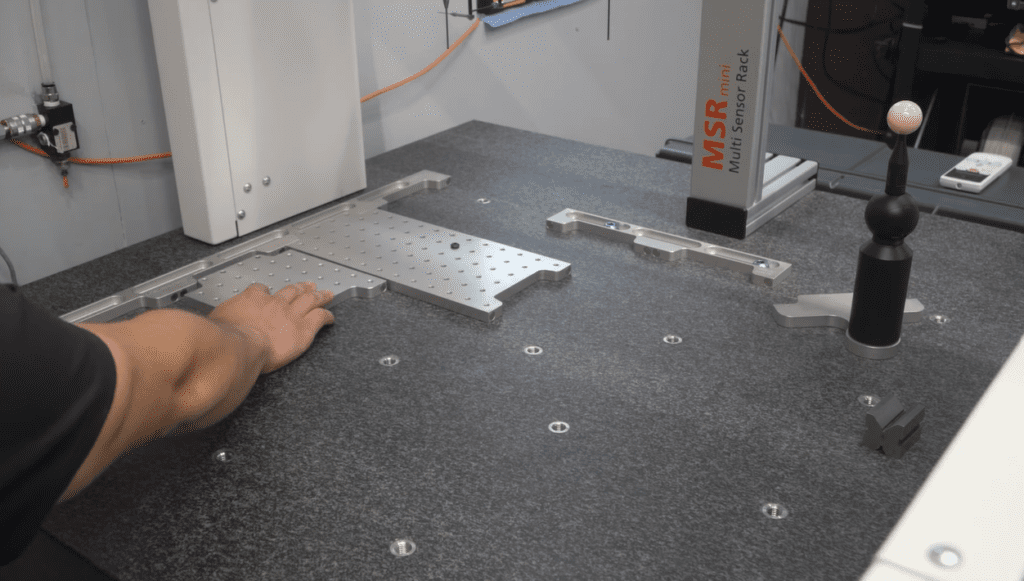

Additionally, horizontal machining centers come equipped with dual pallet changers, facilitating continuous production and decreasing part processing durations. This efficiency arises because while one pallet on the HMC is being machined, another is being prepared with a new workpiece. Once the current part is finished, the pallets rotate, setting up the subsequent piece for machining.

CNC Milling Machine Compared to CNC Machining Center

The machining center generally operates in the same way as other milling machines. Yet, what sets the CNC machining center apart is its automatic tool changer, which traditional milling machines lack. It’s steered by a CNC controller that manages the X, Y, and Z axes, enhancing efficiency with its tool-changing feature.

The horizontal machining center might not be as celebrated as its vertical counterpart, we’ll delve deeper into its attributes, explore its applications, examine its cost, and discuss why it could be a valuable addition to a machine or fabrication workshop.

How Do Horizontal Machining Centers Compare to Vertical Machining Centers?

Both are high-performance, multi-axis tools equipped with rapid spindle speeds, advanced coolant systems, and CNC control technology for optimized high-speed machining.

Vertical Machining Centers (VMCs) are generally more common for multiple reasons. They are more cost-effective compared to their counterparts and operate in a manner that most machinists find intuitive.

However, VMCs do have certain limitations. For instance, they offer only a single work plane, necessitating that the workpiece be repositioned five times to access five faces of a cubic block. This repositioning increases the time spent handling the piece and idle spindle time, necessitating a highly skilled operator.

In contrast, Horizontal Machining Centers (HMCs) are better equipped for projects that require multi-sided machining. These machines usually feature dual integrated pallets that can hold fixtures, allowing one workpiece to be set up while another is being machined. This approach maximizes spindle usage and significantly boosts productivity.

Additional benefits of HMCs include a greater tool storage capacity and improved chip flow, which directs debris away from the workspace. This eliminates the need for periodic machine stoppages for chip removal. Moreover, the option to add a rotary table provides the capability for a fourth axis.

When Should You Opt for a Horizontal Machining Center?

Job shops may not fully utilize the capabilities of an advanced horizontal machining center due to their potentially lower volume of parts production. However, for production shops with continuous, large-scale orders, HMCs are ideal for tasks such as:

- Slotting

- Gear shaping

- Grooving

- Detailed side work on components

- Multi-sided block machining

- Handling of large or weighty parts.

What Is a 5-Axis Horizontal Machining System?

5-axis machining centers have gained popularity, advancing from the conventional 3-axis horizontal systems. Beyond the standard X, Y, and Z axes, these centers incorporate two additional rotary axes, chosen from A, B, and C axes.

In five-axis machining, CNC tools navigate across five distinct axes simultaneously, resulting in a highly efficient and precise operation. By securing the workpiece just once, it undergoes comprehensive machining. This method is particularly suited for crafting intricate components found in aerospace, automotive, medical precision devices, and military sectors.

Notable manufacturers of 5-axis horizontal machining centers are Makino, Kitamura, Okuma, and Mazak. The dimensions of their machine pallets and working spaces can differ.

What is the Cost of a Modern Horizontal Machining Unit?

HMCs are efficient tools that can significantly enhance your business operations. However, they come with a substantial price tag. A Haas EC-630 four-axis horizontal machining center with a 50-tool capacity and dual pallets, for instance, begins at $350,000. Comparable five-axis units from brands like Okuma and Kitamura can exceed $500,000. Even lesser-known models from DMG Mori command prices in the high five figures.

Why Do Businesses Invest in Horizontal Machining Centers?

Certain businesses recognize the robust capabilities of heavy-duty Horizontal Machining Centers (HMCs) in facilitating quicker operational speeds and reduced production cycles. They see these HMCs as catalysts for expansion, as the versatility they offer unlocks new opportunities in work previously deemed unfeasible. Armed with these advanced machines, workshops can more aggressively price their services, confident that they can deliver superior components more quickly due to streamlined setups and automated processes.